1

Introduction

The Diamond Wire Technology Millennium Capstan Saws are designed to make a series of

programmed cuts in a variety of materials. Slicing saws are designed to allow you to make up to

100 cuts (50 cuts with the Dicing Option) from a single program. Furthermore, each cut can be

programmed to a different width if desired. With the Dicing option, you can make up to 24 cuts

each in up to 4 different rotational positions from a single program. Furthermore, each dicing cut

can be programmed to a different width if desired. This flexibility permits the operator to cut

consistent slices, squares, and even complex polygons.

The cutting action is similar to that of a coping saw. A diamond-impregnated wire is tensioned

between pulleys above the part to be cut. The wire moves down through the material at a velocity

specified by the operator, or at a velocity that is automatically calculated based on wire bow.

Due to the small diameter and flexibility of diamond wire, a small angle forms between the part

and the pulleys as cutting proceeds. It is, in fact, this wire bow that imparts the necessary force

upon the specimen and allows cutting to occur. The saws incorporate a Bow Sensor which

continuously monitors wire deflection and automatically adjusts the velocity of the yoke drive to

maintain a constant bow, and hence a constant cutting force.

Please read the entire manual prior to undertaking any cutting operation. The manual contains a

considerable amount of interrelated information. A thorough understanding will translate into better

results.

Mechanical Setup

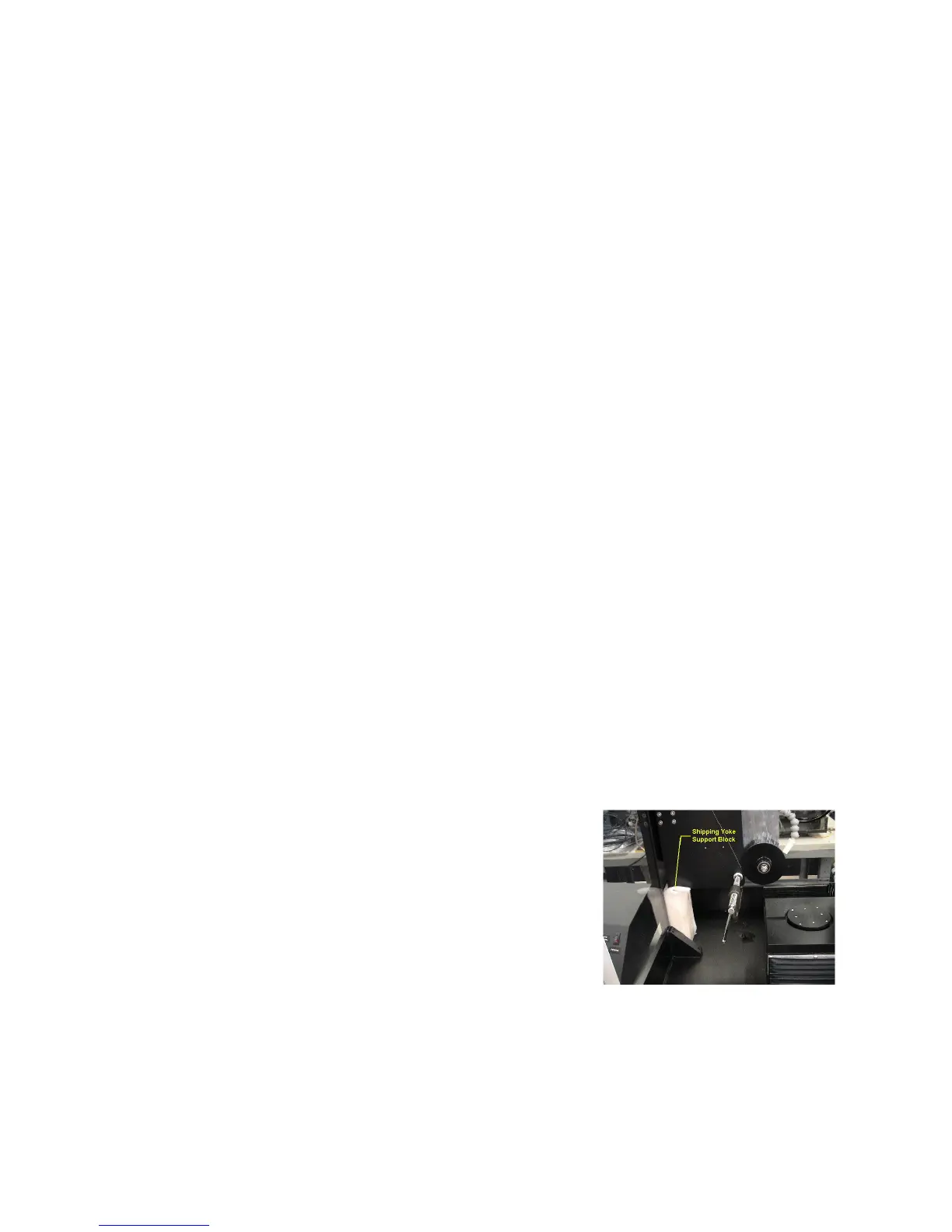

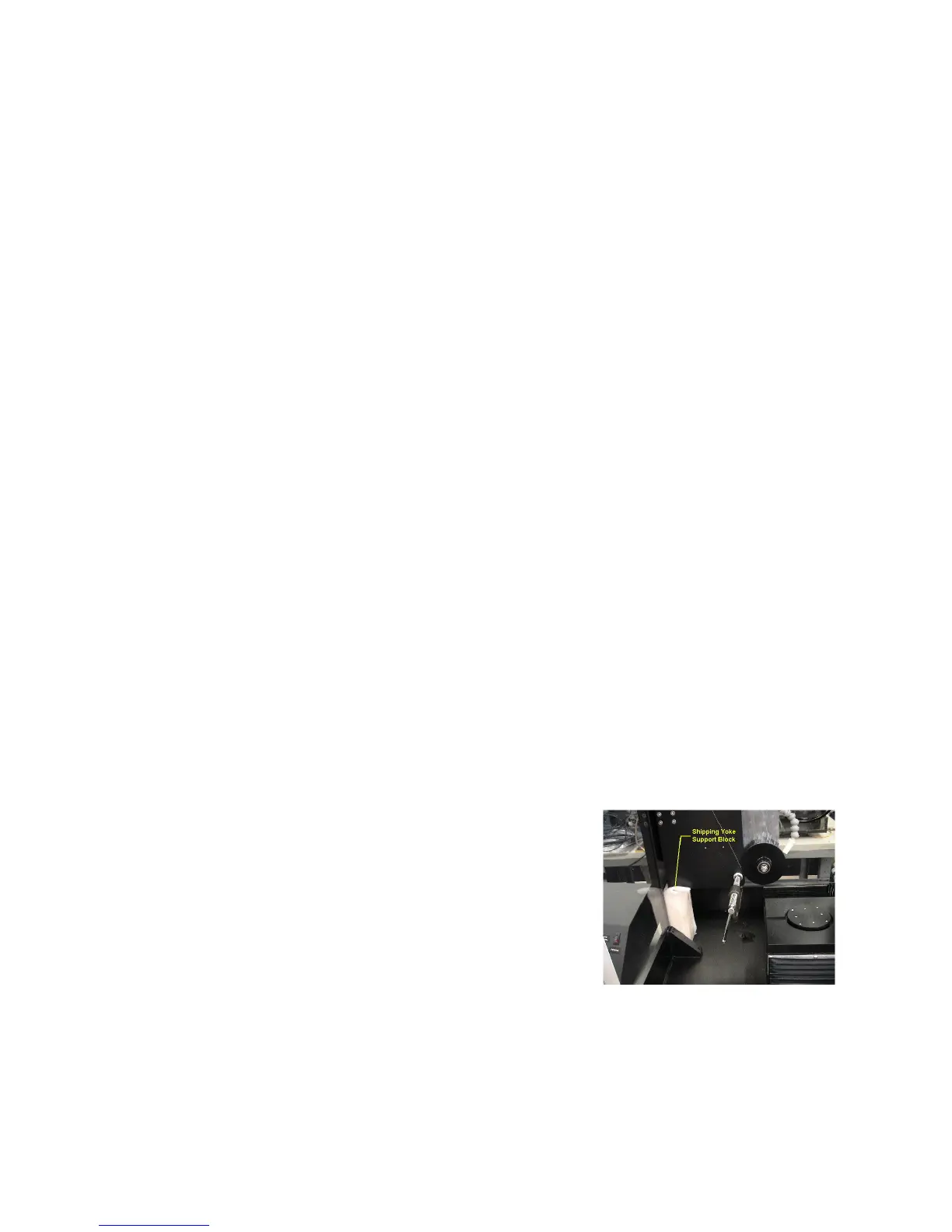

Shipping Considerations

Remove the yoke support block. To do this, jog the yoke up

until the block can be easily removed. Refer to the section,

Jogging the Actuators on page 7.

Air pressure is required to maintain wire tension. Since the saw is pre-

wired, the tensioner pulleys have been held in their outward position

with packing material to provide wire tension during shipping.

DO

NOT REMOVE THE PACKING MATERIAL HOLDING THE

TENSIONER PULLEYS UNTIL AFTER AIR AND POWER HAVE

BEEN APPLIED TO THE SAW.

Loading...

Loading...