E

edwardsamandaAug 10, 2025

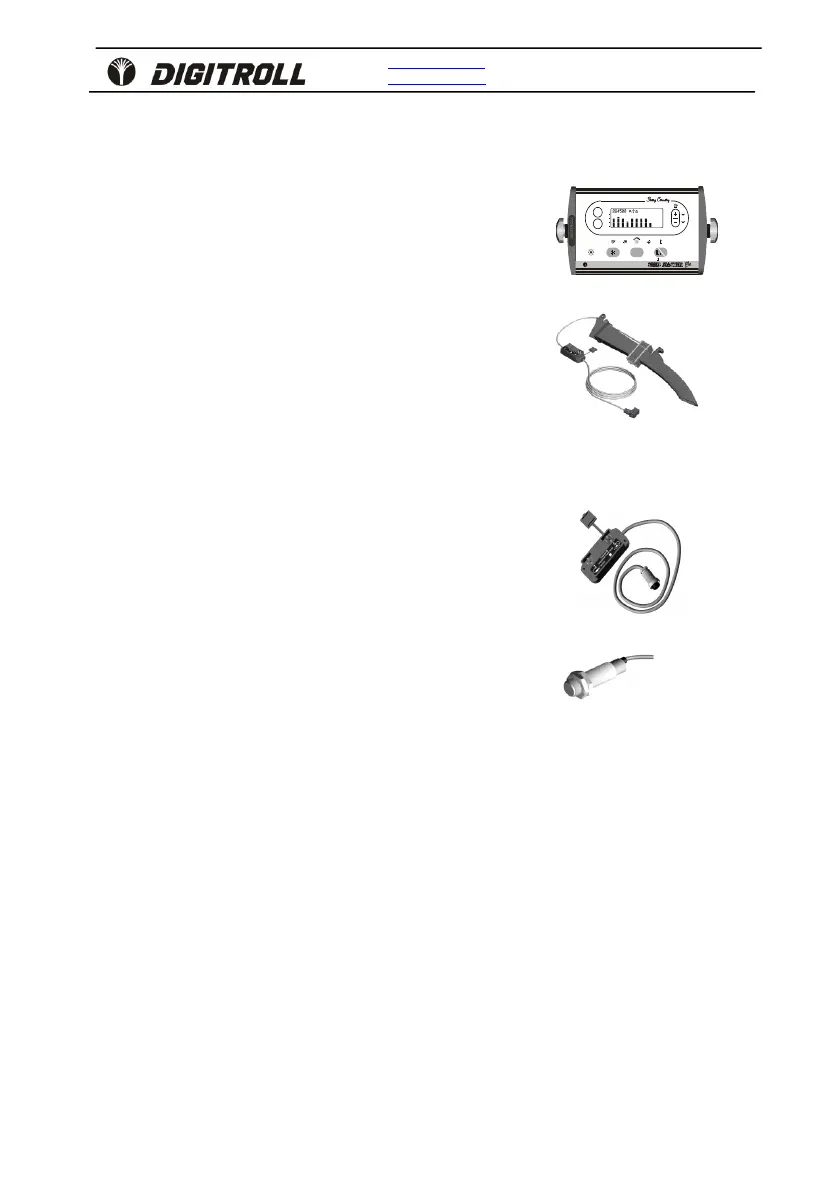

What to do if the 'Power Out' LED on my Digitroll SEED MASTER Plus monitor doesn't light up or blinks?

- RRonald FerrellAug 10, 2025

If the 'Power Out' LED on your Digitroll Control Systems monitor is not lighting up or is blinking, it could be due to an external short circuit, a cable pinch, or a defective seed module. First, disconnect the modules from the monitor. If that doesn't work, systematically disconnect the modules starting from the monitor side. If the LED lights up, reconnect and disconnect the next connector until you find the short circuit area. This disconnection process can also help you identify a defective unit causing the short circuit.