D I V E R S I T E C H O M - G F C M

3.2 - Compressed Air Installation

NOTE: Only dry compressed air is to be used with the machine. The unit requires a minimum

of 80 CFM at 90 PSI to operate properly.

Connect compressed air (90 PSI) to the ½” inlet fitting located on the back of the unit. It is

recommended to install a cut-off valve on the line for safety purposes. A regulator will be

necessary to step down the supply air if the shop pressure is above 100 PSI. NOT complying

may result in damage to the unit’s components and reduce performance. A 1/2” NPT supply

line is required.

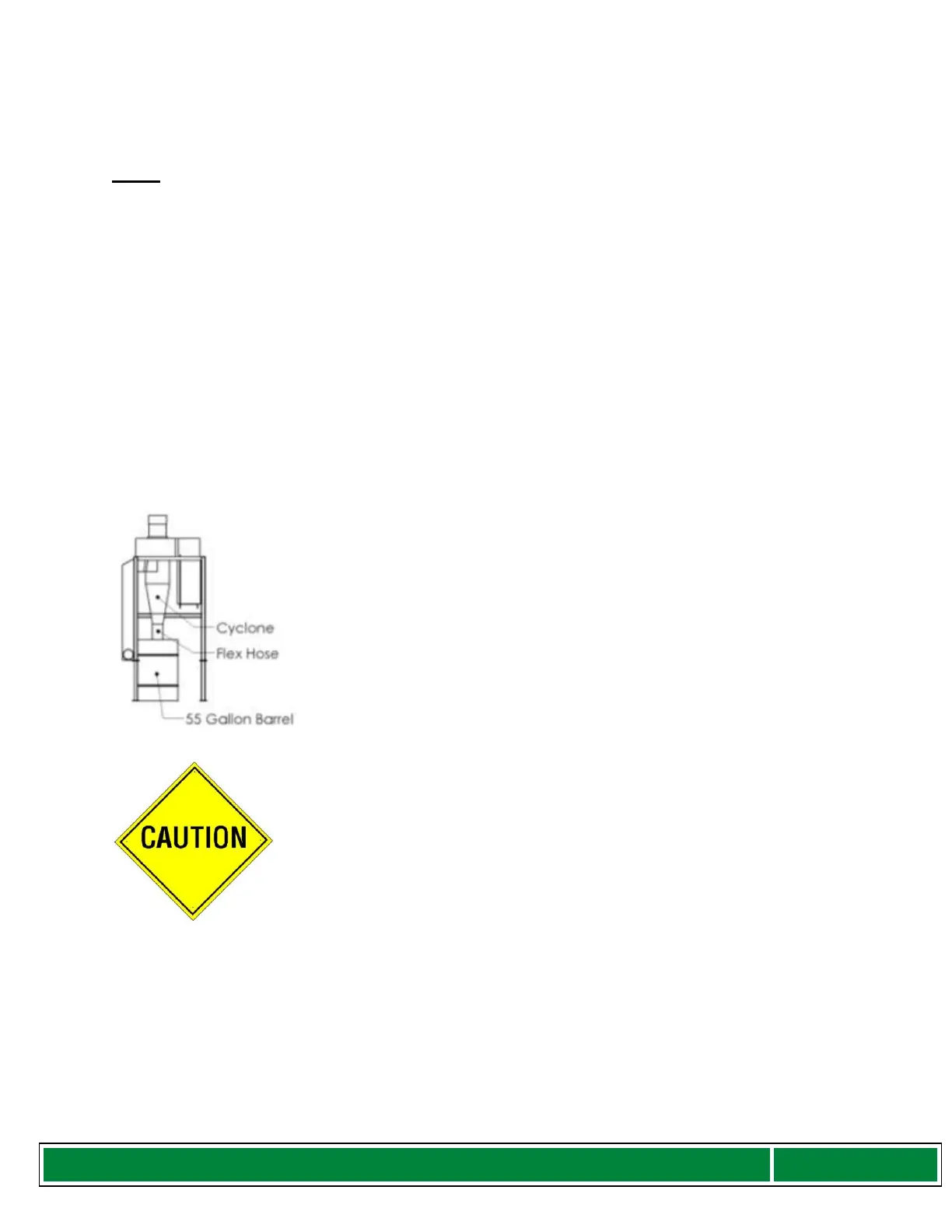

3.3 - Installation of the Barrel

Step 1: Slide barrel under cyclone cone.

Step 2: Apply liberal amounts of silicone sealant to the barrel inlet collar.

Step 3: Slide the flexible hose over the collar.

Step 4: Fasten the flexible hose to the collar using the provided hose clamp.

If Cyclone to Barrel connection is not fully sealed, the cyclone will not

operate properly.

Loading...

Loading...