D I V E R S I T E C H O M - G F C M

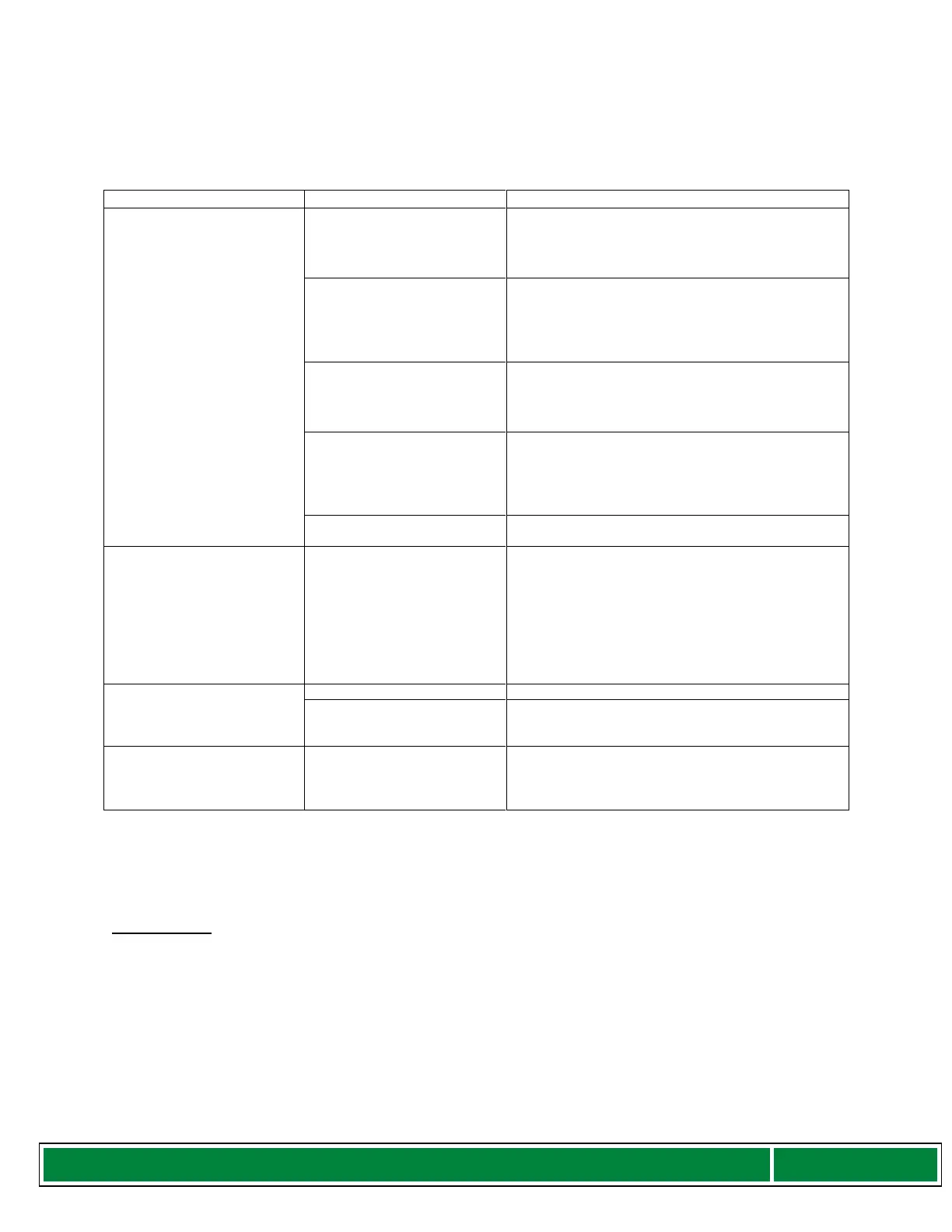

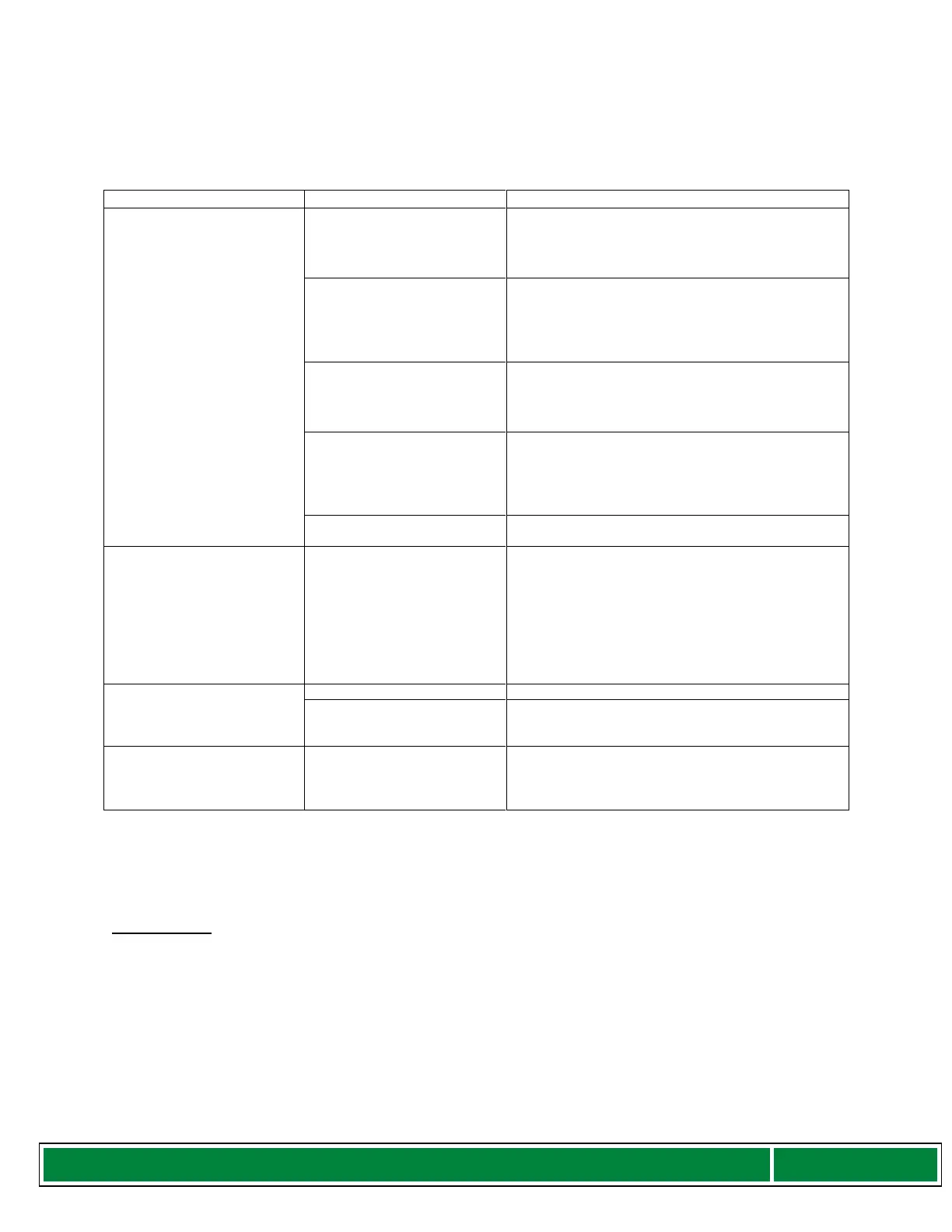

5.0 - Troubleshooting List for Injection Cleaning System

Power is not supplied to PC board.

Ensure the unit is plugged in; ensure there is no loose or short

wiring between primary & secondary of transformer and the

24VAC power inlets of PC Board.

Filter is not sealed properly

Check the compression mechanism on top of the inner chamber

lid. Insert appropriate Spacer. (Refer to Filter Spacer Chart)

Loose connection between PC board

and motor.

Check motor connection. When the “UP” light is ON, the motor

should be rotating the nozzle upwards; and downwards when

the “DOWN” light is ON. (Refer to the electrical diagram)

This could be a result of the nozzle

being jammed, or of something

restricting free movement of the

nozzle.

Locate and repair the cause of the physical restriction before

operating the system.

Limit switch needs alignment

Push limit switch forward or backwards to align with the Nozzle

Assembly switch disc

System is NOT turning and no air

comes out of the nozzle.

Upon a cleaning cycle, the “SOLN1” light turns ON indicating

power is being supplied to the solenoid.

Check the wiring between the PC board and the solenoid for

any possible bad connections.

Check if solenoid is operational. This can be done by jumping

the solenoid leads to the secondary side of the transformer.

(24VAC)

If both wiring and solenoid are in order, the PC board might

need to be changed.

System turns but no air comes out

of the nozzle.

Ensure that air pressure is 80-100psi and Minimum 80CFM

The nozzle is blocked by dirt or

other contaminant.

Remove blockage from the nozzle.

Check if pneumatic filter is filtering air properly. Its filter unit

might need to be replaced.

Not enough air coming out of the

nozzle.

There is an air leak in the pneumatic

system.

Verify pneumatic system for leaks and tighten or change hose

clamps or hoses.

For any other inquiry, please contact Diversi-tech at 1-800-361-3733.

5.1 - Debugging

Things to check

When the machine is first plugged in, the mechanism will move to a “home” position. Once the nozzle is at home

position, the system is ready. The cleaning cycle is controlled by a microprocessor based PC board located in the

control box. The microprocessor has been programmed to turn on the cleaning system once the start button is

pressed and released, and the filter is sealed. The nozzle will travel from its home position (located at the bottom)

through the top and back down to home. The home and top positions are sensed by Limit Switch and Proximity

Sensor respectively. Simultaneously, when the gear motor is engaged, an in-line solenoid opens and allows

compressed air to reach the nozzle or the pneumatic vibrator motor. If for some reason the lid is open before the

cleaning system has had a chance to terminate the cycle, the system will shut itself and the unit will resume from

where it left off once the Cabinet lid is closed.

Loading...

Loading...