1592026020 XW60K GB R2.1 22.06.2012.doc XW60K 5/6

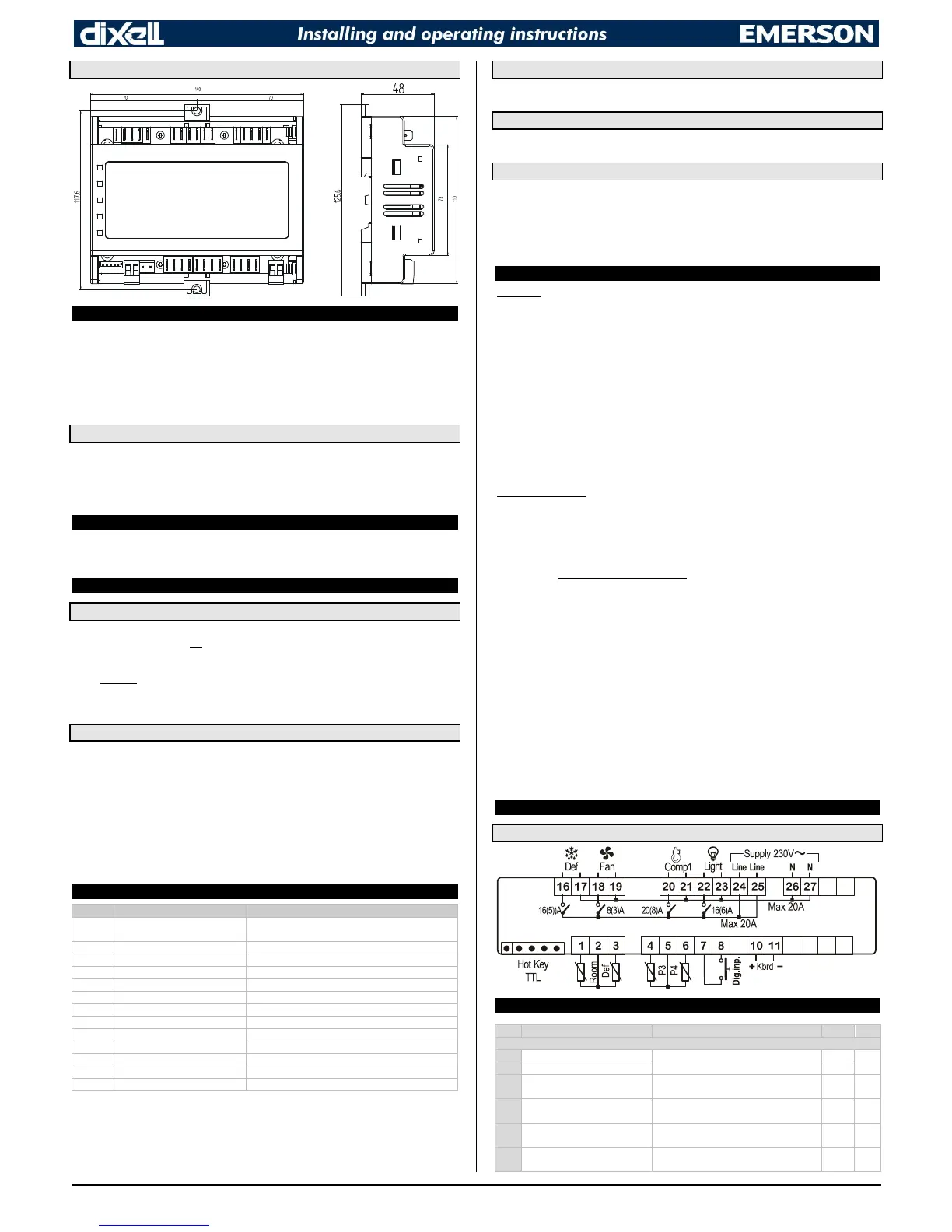

10.1 XW60K – 8 DIN CASE - DIMENSIONS

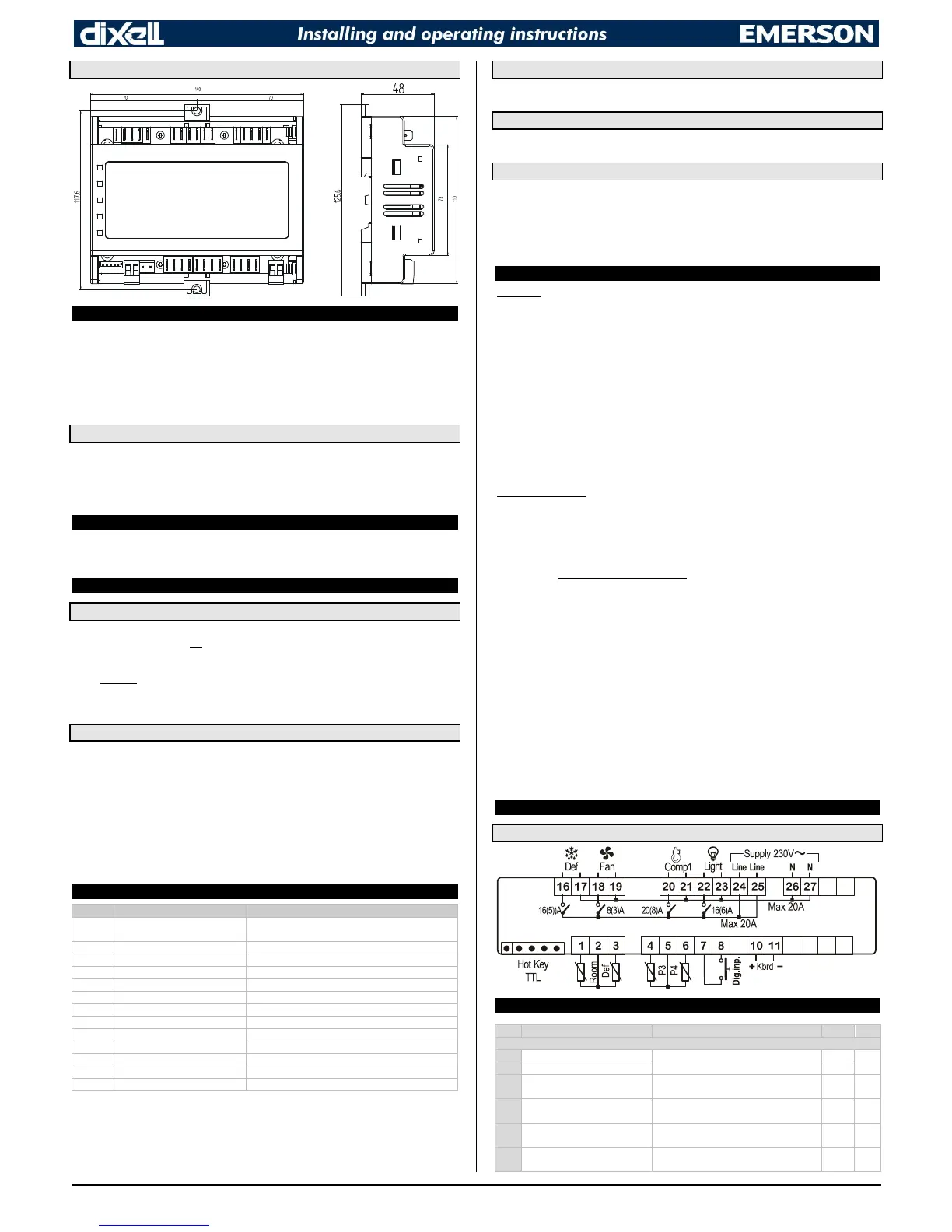

11 ELECTRICAL CONNECTIONS

XW60K is provided with screw terminal blocks to connect cables with a cross section up to 2.5 mm

2

for

the RS485 (optional) and the keyboard. To connect the other inputs, power supply and relays, XW60K

is provided with Faston connections (6.3mm). Heat-resistant cables have to be used. Before

connecting cables make sure the power supply complies with the instrument’s requirements. Separate

the probe cables from the power supply cables, from the outputs and the power connections. Do not

exceed the maximum current allowed on each relay, in case of heavier loads use a suitable external

relay.

NOTE: the maximum current allowed for all the loads is 20A.

11.1 PROBE CONNECTIONS

The probes shall be mounted with the bulb upwards to prevent damages due to casual liquid

infiltration. It is recommended to place the thermostat probe away from air streams to correctly

measure the average room temperature. Place the defrost termination probe among the evaporator

fins in the coldest place, where most ice is formed, far from heaters or from the warmest place during

defrost, to prevent premature defrost termination.

12 TTL/RS485 SERIAL LINE

The TTL connector allows, by means of the external module TTL/RS485 (XJ485CX), to connect the

unit to a network line ModBUS-RTU compatible as the dIXEL monitoring system. The same TTL

connector is used to upload and download the parameter list of the “HOT-KEY”.

13 HOW TO: USE OF THE PROGRAMMING “HOT KEY”

13.1 PROGRAM A HOT-KEY FROM AN INSTRUMENT (UPLOAD)

1. Program one controller with the front keypad.

2. When the controller is ON, insert the “HOT-KEY” and push UP button; the “uPL” message

appears followed a by a flashing “End” label.

3. Push SET button and the “End” will stop flashing.

4. Turn OFF the instrument, remove the “HOT-KEY” and then turn it ON again.

NOTE: the “Err” message appears in case of a failed programming operation. In this case push again

button if you want to restart the upload again or remove the “HOT-KEY” to abort the operation.

13.2 PROGRAM AN INSTRUMENT BY USING A HOT-KEY (DOWNLOAD)

1. Turn OFF the instrument.

2. Insert a pre-programmed “HOT-KEY” into the 5-PIN receptacle and then turn the Controller

ON.

3. The parameter list of the “HOT-KEY” will be automatically downloaded into the Controller

memory. The “doL” message will blink followed a by a flashing “End” label.

4. After 10 seconds the instrument will restart working with the new parameters.

5. Remove the “HOT-KEY”.

NOTE: the message “Err” is displayed for failed programming. In this case turn the unit off and then on

if you want to restart the download again or remove the “HOT-KEY” to abort the operation.

14 ALARM SIGNALS

Message

parameters Con and CoF.

P2 Evaporator probe failure Alarm output ON; Other outputs unchanged

P3 Probe 3 probe failure Alarm output ON; Other outputs unchanged

P4 Probe 4 probe failure Alarm output ON; Other outputs unchanged

HA Maximum temperature alarm Alarm output ON; Other outputs unchanged

LA Minimum temperature alarm Alarm output ON; Other outputs unchanged

HA2 Condenser high temperature It depends on the AC2 parameter

LA2 Condenser low temperature It depends on the bLL parameter

dA Door open Compressor and fans restarts

EA External alarm Output unchanged.

CA Serious external alarm (i1F=bAL) All outputs OFF.

CA Pressure switch alarm (i1F=PAL) All outputs OFF

EE Data or memory failure Alarm output ON; Other outputs unchanged

The alarm message is displayed until the alarm condition is recovery.

All the alarm messages are showed alternating with the room temperature except for the “P1” which is

flashing.

To reset the “EE” alarm and restart the normal functioning press any key, the “rSt” message is

displayed for about 3 sec.

14.1 SILENCING BUZZER

Once the alarm signal is detected the buzzer can be silenced by pressing any key. Buzzer is mounted

in the keyboard and it is an option.

14.2 “EE” ALARM

The dIXEL instruments are provided with an internal check for the data integrity. The “EE” alarm

flashes when a failure in the memory data occurs. In such cases the alarm output is enabled.

14.3 ALARM RECOVERY

Probe alarms: “P1” (probe1 faulty), “P2”, “P3” and “P4”; they automatically stop 10 sec after the probe

restarts normal operation. Check connections before replacing the probe.

Temperature alarms “HA”, “LA” “HA2” and “LA2” automatically stop as soon as the temperature

returns to normal values.

Alarms “EA” and “CA” (with i1F=bAL) recover as soon as the digital input is disabled.

Alarm “CA” (with i1F=PAL) recovers only by switching off and on the instrument.

15 Technical data

Keyboards

Housing: self extinguishing ABS

Case: T620 and T620T: facia 38x185 mm; depth 23mm

V620: facia 72x56 mm; depth 23mm

CX620: facia 75x36 mm; depth 23mm

Mounting: T620T panel mounting in a 150x31 mm panel cut-out with the 2 metal brackets supplied.

T620: panel mounting in a 150x31 mm panel cut-out with two screws. 3 x 2mm. Distance

between the holes 165mm

V620: panel mounting in a 56x72 mm panel cut-out with two screws. 3x2mm. Distance

between the holes 40mm

CX620: panel mounting in a 71x29mm panel cut-out

Protection: IP20; Frontal protection: IP65 with frontal gasket

Connections: Screw terminal block 2.5 mm

2

Power supply: from XW60K power module

Display: 3 digits, red LED, 14.2 mm high

Optional output: buzzer.

Power module XW60K

Case: 8 DN: 140X176X148

Connections: Screw terminal block 2.5 mm

2

heat-resistant wiring and 6.3mm Faston

Power supply: 230Vac or. 110Vac 10% or 24Vac

Power absorption: 10VA max

Inputs: 4 NTC or PTC probes

Digital inputs: 1 free voltage

Relay outputs: Total current on loads MAX. 20A

Compressor: relay SPST 20(8) A, 250Vac

Fan: relay SPST 8(3) A, 250Vac

Defrost: relay SPST 16(5) A, 250Vac

Light (oA3): relay SPST 16(5) A, 250Vac

Serial output: TTL standard

Communication protocol: Modbus - RTU

Data storing: on the non-volatile memory (EEPROM)

Kind of action: 1B

Pollution degree: normal

Software class: A

Operating temperature: 0 to 60°C (32 to 140°F)

Storage temperature: -25 to 60°C (-13 to 140°F)

Relative humidity: 20 to 85% (no condensing)

Measuring and regulation range:

NTC probe: -40 to 110°C (-58 to 230°F)

PTC probe: -50 to 150°C (-58 to 302°F)

Resolution: 0.1°C or 1°C or 1°F (selectable)

Accuracy (ambient temp. 25°C): ±0.5°C ±1 digit

16 CONNECTIONS

16.1 XW60K

17 Default setting values

Label

Loading...

Loading...