9

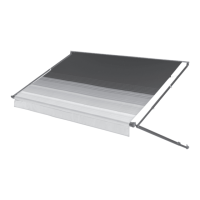

FIG. 16

Wall

Up

90°

Bumper

(Anti-Billow Stop)

#10 Screw

(Self Drilling)

#10 Screw

(Self Drilling)

End Cap

LH Arm

FIG. 17

Anti-Billow Stop

#10 Screw

(Self Drilling)

Anti-Billow Bracket

End Cap

Edge

Protector

45°

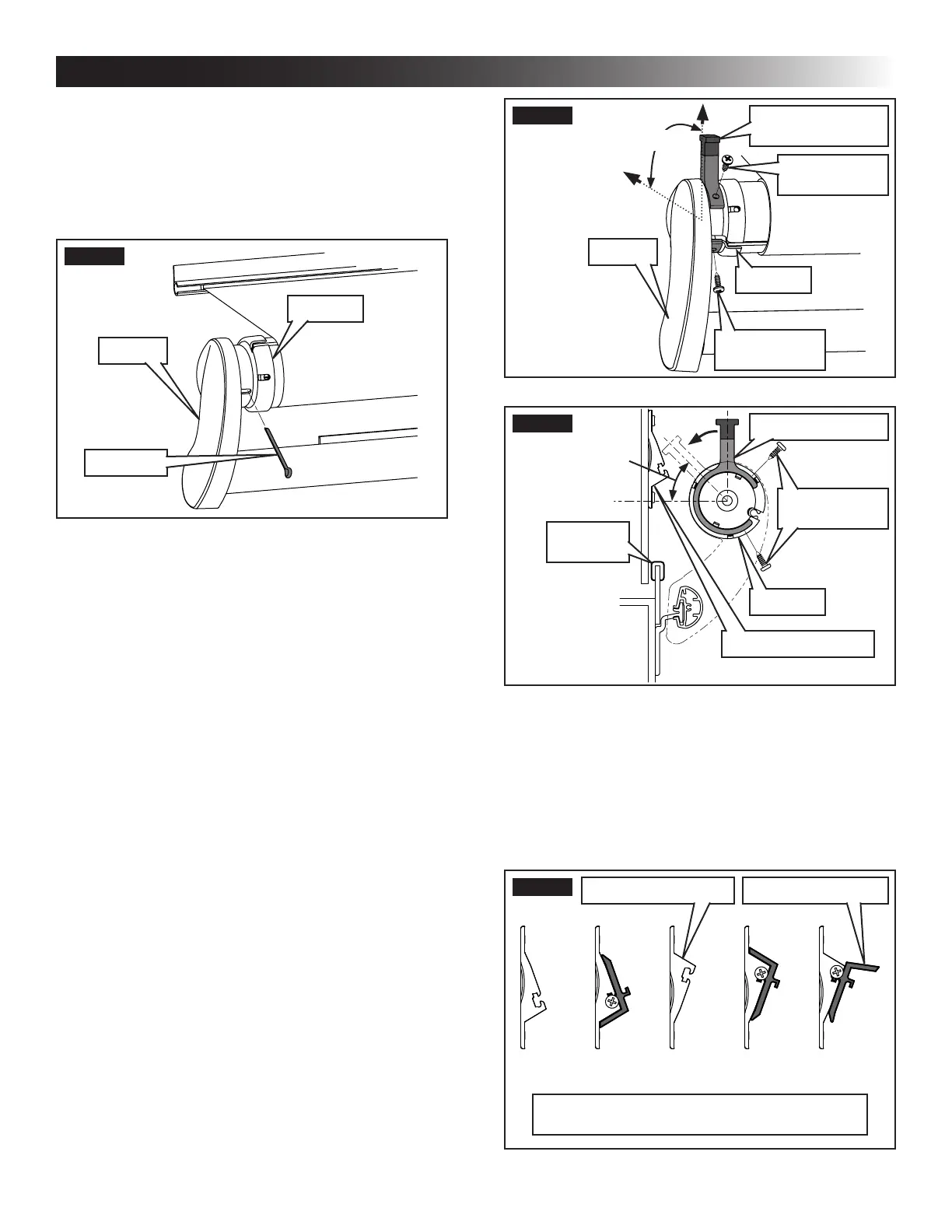

2. Determine required conguration of anti-billow

bracket and spacer (spacing from RV wall) to

ensure anti-billow stop will NOT rotate past a

45° angle (toward RV wall). See (FIG. 17) &

(FIG. 18).

The anti-billow bracket and anti-billow

spacer can be congured for a spacing

range of 5/16″ to 1 1/2″.

FIG. 18

3/4″ 1″ 1 1/2″1/2″5/16″

Anti-Billow Bracket / Spacer Conguration

(Spacing From RV Wall)

Anti-Billow SpacerAnti-Billow Bracket

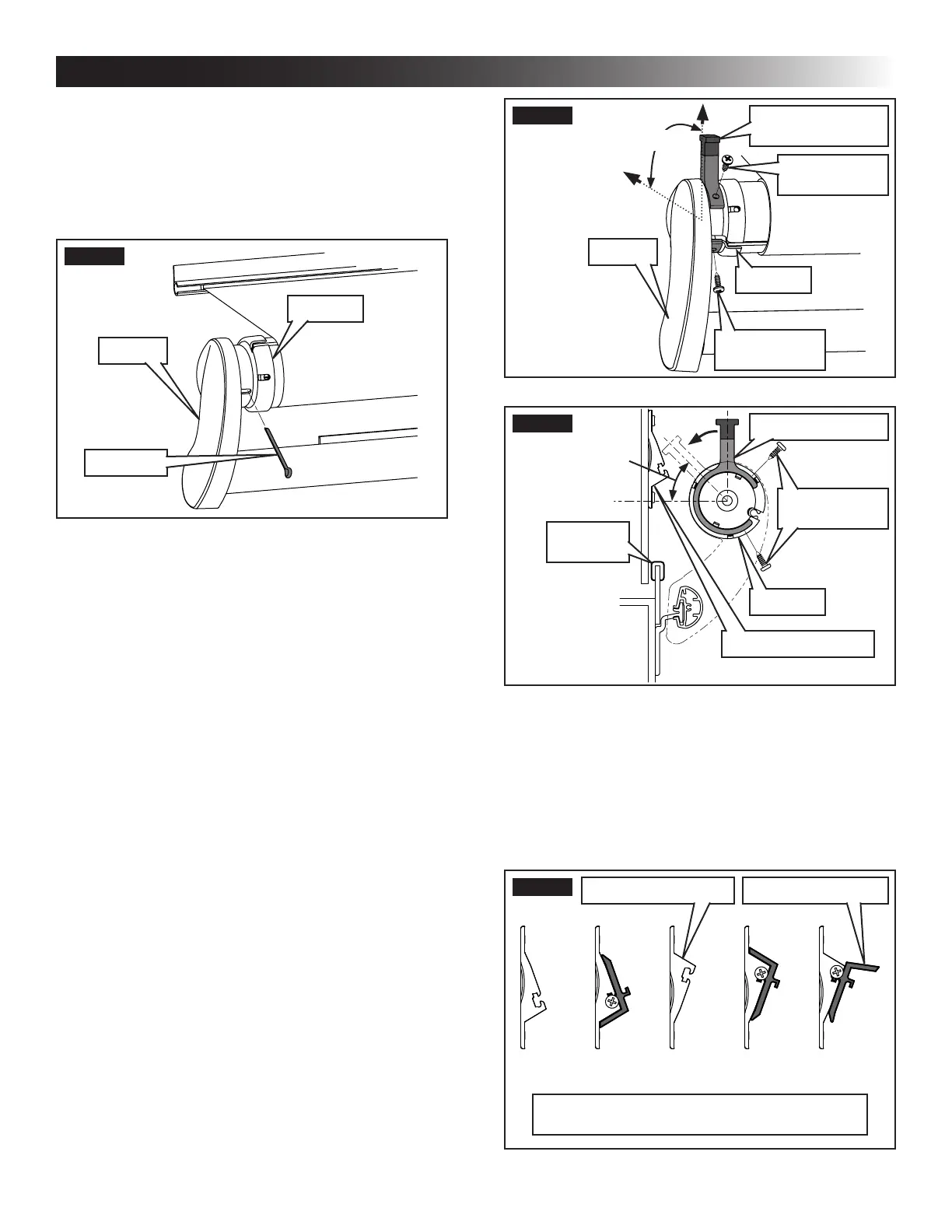

plicable) from LH torsion rod (at LH end cap).

See (FIG. 15).

Removing cotter pin will release factory

preset tension. To facilitate removal, ro-

tate the fabric roller tube (as if unrolling

awning) by pulling bottom of tube toward

you while pulling on cotter pin.

FIG. 15

End Cap

LH Arm

Cotter Pin

10. Repeat step (9) for RH end.

D. Install Anti-Billow Stop

1. Cotter pins MUST be removed

from Slide Topper end caps BEFORE operating

slide out room. Otherwise, damage to the Slide

Topper and/or slide out room will occur.

With slide out room (and awning) still closed,

place anti-billow stop on end cap. See (FIG. 16)

& (FIG. 17).

a. Determine onto which end cap anti-billow

stop will be installed.

Slide Toppers 198″ or wider REQUIRE

an anti-billow stop (and bracket) at

BOTH end caps, and a cradle kit for

center support. See “B. Optional Com-

ponents & Kits” on page (4) to or-

der.

b. Place anti-billow stop on desired end cap

with opening facing AWAY from awning rail

(when bumper is pointed straight up).

c. Position anti-billow stop with bumper pointed

straight up (vertical). Then tape in place.

If either screw hole (in anti-billow stop)

interferes with existing holes or open-

ings in end cap, rotate anti-billow stop

away from RV wall (no more than 30°

from vertical position) before taping.

INSTALLATION

Loading...

Loading...