Power Train Disassembly & Assembly

Remove the Spindle and Brake

Spider

To prevent serious personal injury and possible

damage to components, be very careful when

using lifting devices during service and

maintenance procedures.

•

Inspect to make sure that neither lifting strap is

damaged.

•

Do not subject lifting loops or lifting straps to any

shock or drop loading.

Removal of the capscrews allows the spindle and

brake assembly to separate. They can fall from the

planetary axle housing and cause damage to

components and serious personal injury.

1. To prevent the spindle (29) and the brake spider

from falling after all the mounting capscrews (27)

are removed, use one of the following procedures:

a. Use a lifting device to support the spindle during

disassembly.

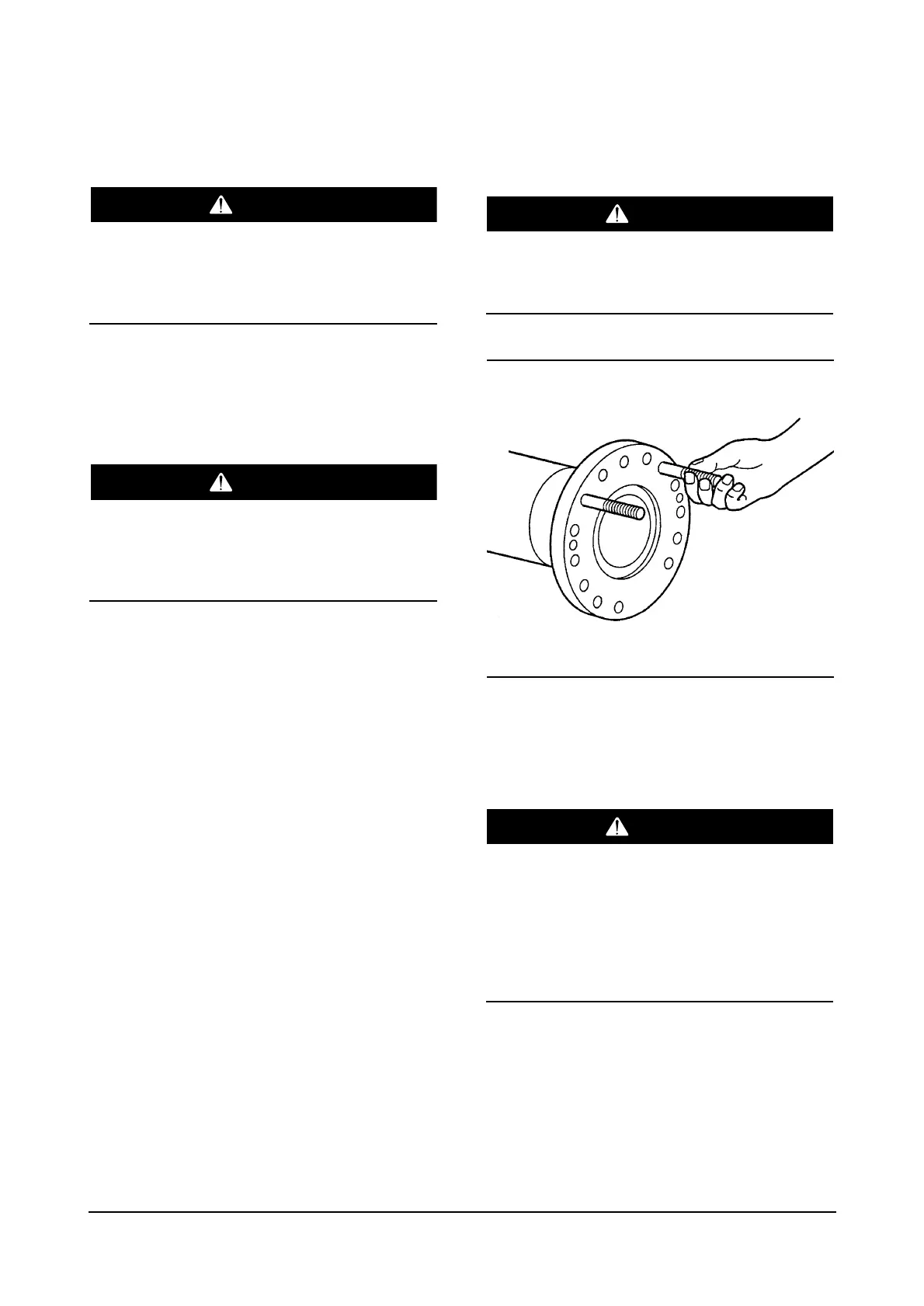

b. Remove only two capscrews. Replace them

with two temporary 0.75 inch-10 UNC thread

studs 4 inches (102 mm) long before the

remaining capscrews are removed.

– Install one stud at the 11 o’clock position.

– Install one stud at the one o’clock position.

2. Remove the two capscrews and washers that

mount the clamp around the brake camshaft

housing tube to the axle housing.

3. Remove the capscrews (27) and washers (28) that

mount the brake spider and spindle (29) to the

axle housing.

4. Remove the brake spider and air chamber

assembly from the spindle (29).

5. Remove the spindle (29) from the axle housing. If

necessary, tap lightly on the spindle to loosen the

pilot fit and to overcome the adhesion due to cured

gasket material in the flange joint.

Assemble the Spindle, Brake

Spider and Brake

To prevent serious eye injury, always wear safe

eye protection when you perform vehicle

maintenance or service.

1. Install two temporary studs (0.75 inch-10 threads,

approximately 4 inches long) into the axle housing

flange. Install the studs at the 11 o’clock and 1

o’clock positions.

When you apply some silicone gasket materials,

small amounts of acid vapor are present. To

prevent possible serious injury, the work area

must be well-ventilated. If the silicone gasket

material gets into your eyes, flush them with water

for 15 minutes. Have your eyes checked by a

doctor as soon as possible.

Loading...

Loading...