Power Train Disassembly & Assembly

Brakes

Disassemble Brakes

Remove Wheel Components

To prevent serious eye injury, always wear safe

eye protection when performing maintenance or

service.

Do not work under a vehicle supported only by

jacks. Jacks can slip or fall over and cause serious

personal injury.

1. Use a jack under the axle being serviced to raise

the vehicle.

2. Install jack stands under each corner of the vehicle

to hold it in position.

When you work on a spring chamber, carefully

follow the service instructions of the chamber

manufacturer. Sudden release of a compressed

spring can cause serious personal injury.

3. If the brake has spring chambers, carefully cage

and lock the spring so that the spring cannot

actuate during disassembly.

4. Fully release the slack adjusters so that the shoes

retract and the drums will clear the linings.

5. Use standard procedures to remove the wheels

and drums from the axle.

Remove Brake Shoes

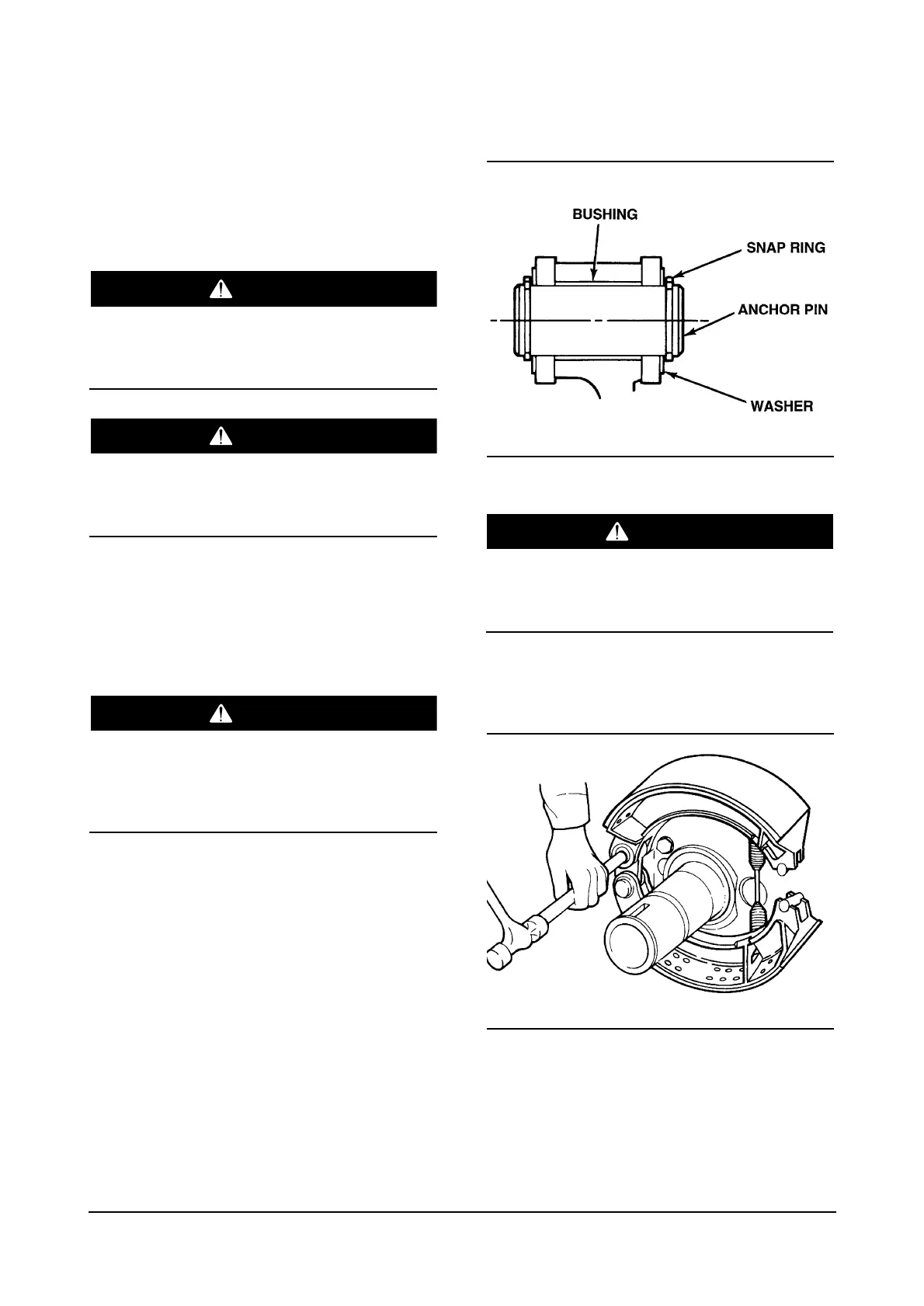

Wear safe eye protection. Do not hit steel parts

with a steel hammer. Pieces can break off and

cause serious personal injury.

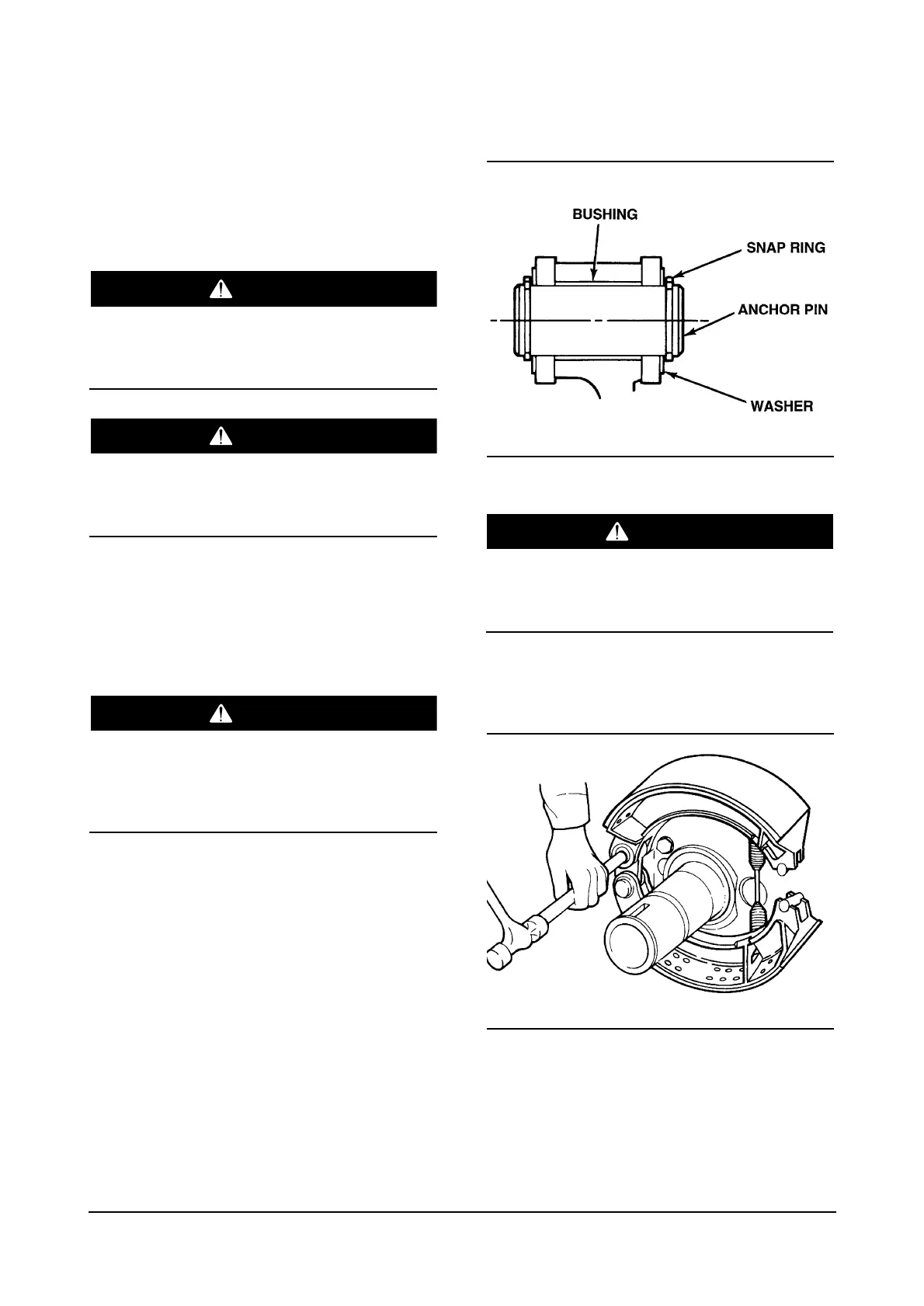

1. Remove any anchor pin snap rings, washers,

retainers, felts, seals or set screws, as needed.

2. Remove the top anchor pin with a brass drift.

Loading...

Loading...