Power Train Disassembly & Assembly

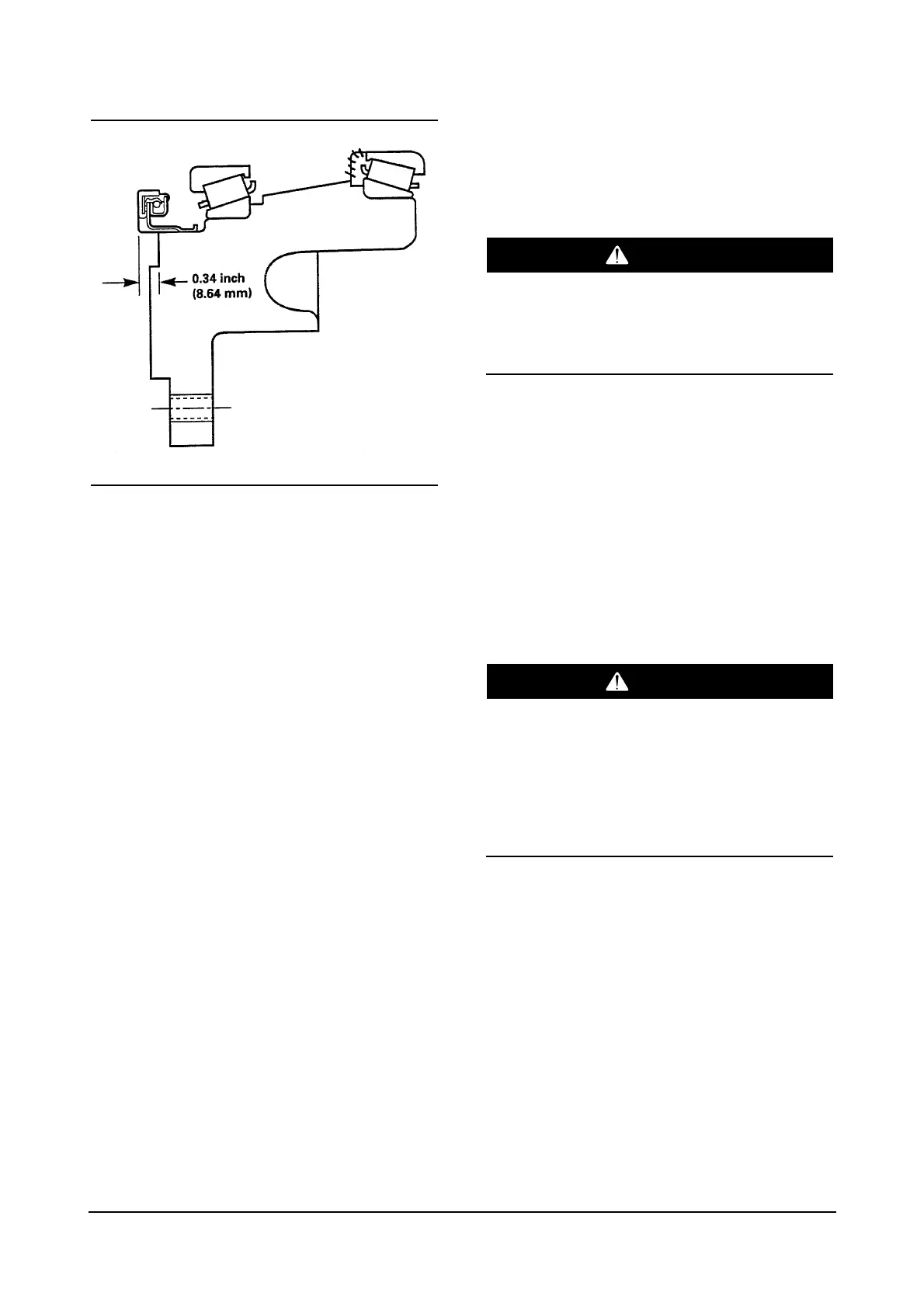

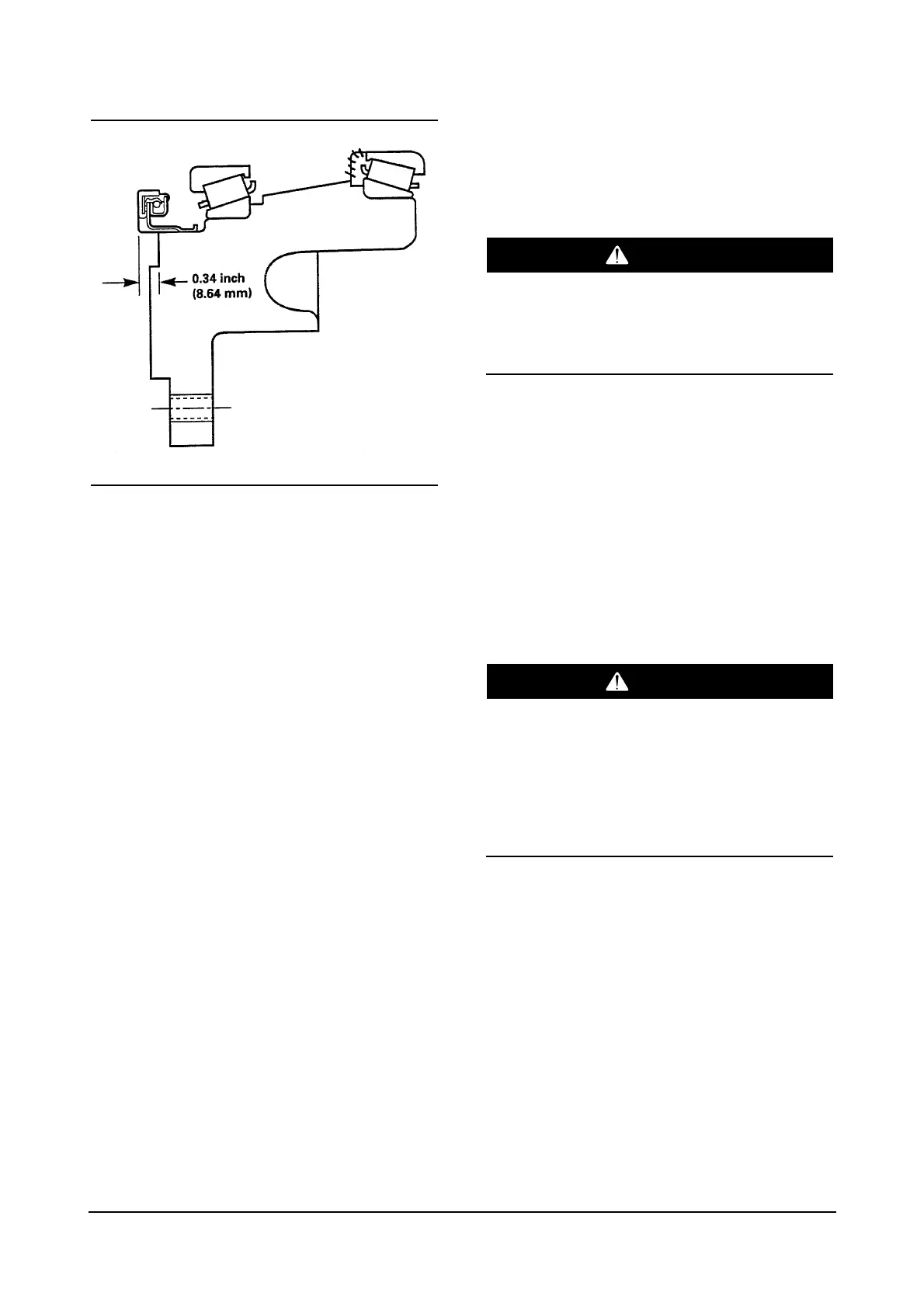

4. Use the correct oil seal driver to install the wheel

hub oil seal (26). Press the seal into the hub until

the standout from the hub machined face is 0.34

inch (8.64 mm).

5. Apply a light film of axle lubricant to the hub oil

seal (26) rubber ribs in the oil seal bore.

6. Install the wheel hub, inner bearing and oil seal

assembly onto the spindle (29). Keep the hub

assembly aligned with the spindle.

7. Apply axle lubricant to the outer bearing cone (18)

rollers. Install the outer bearing cone into the

wheel hub (23).

8. Install the wheel bearing adjusting nut (17). The

dowel pin in the nut must face OUTWARD.

Adjust the wheel Bearing Preload

NOTE : To adjust the wheel bearing preload, the

bearings must be seated and the rollers in proper

alignment.

Use a brass or leather mallet for assembly and

disassembly procedures. Do not hit steel parts

with a steel hammer. Pieces of a part can break off

and cause serious personal injury.

1. Install the wheel bearing adjusting nut (17).

Tighten the nut 400 lb•ft (542 N•m).

2. Rotate the hub (23) in both directions. At the same

time, rap the hub several times with a brass or

plastic mallet.

3. Tighten the nut to 400 lb•ft (542 N•m) again.

4. Back off the nut approximately 1/4 turn to relieve

the preload produced in Step 3.

5. Tighten the nut to 200 lb•ft (271 N•m).

Do not back-off the adjusting nut. The adjusting

nut dowel pin must be carefully aligned within a

ring gear tooth spline to avoid damage to the pin.

A damaged dowel pin will cause the adjusting nut

to back-off and loosen a wheel during vehicle

operation. This can result in serious personal

injury.

6. Carefully align the adjusting nut dowel pin (16)

within a ring gear (15) tooth spline to avoid

damage to the dowel pin. Tighten the adjusting nut

to produce the proper alignment. Do not back-off

the adjusting nut.

7. Install the planetary ring gear (15) onto the spindle

(29). The dowel pin in the adjusting nut (17) must

engage the hole in the ring gear face to allow the

ring gear to seat against the adjusting nut.

8. Apply a thin layer of axle grease to the face of the

sun gear thrust washer (14).

Loading...

Loading...