- 138 -

LP Engine G430(3.0L) Base Engine Service Procedure

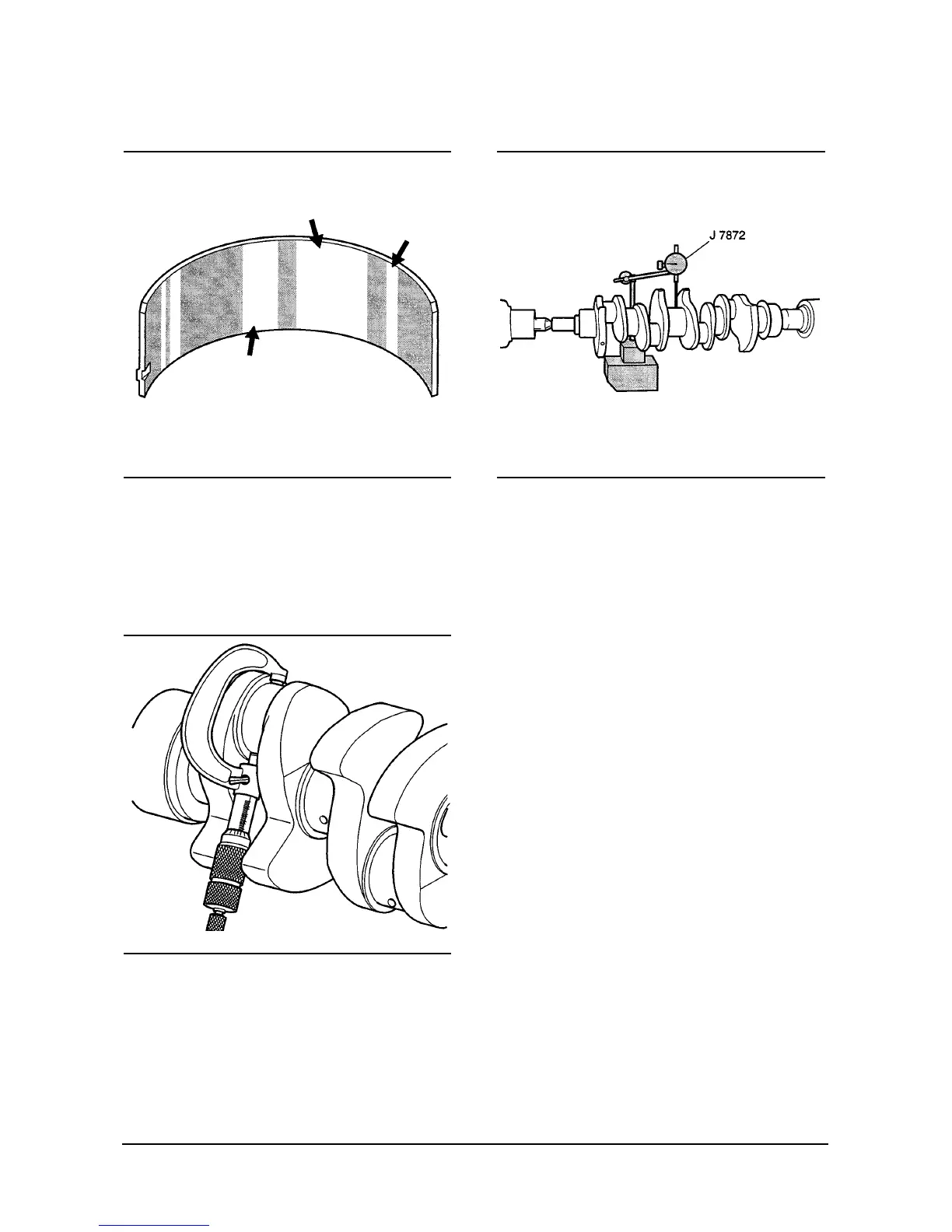

8. Inspect the crankshaft bearings for improper

seating indicated by bright, polished sections of the

bearing.

• If the lower half of the bearing is worn or

damaged, both the upper and lower halves must

be replaced.

9. Measure the crankpins for out-of-round, taper or

undersize with a micrometer. Refer to Engine

Mechanical Specifications.

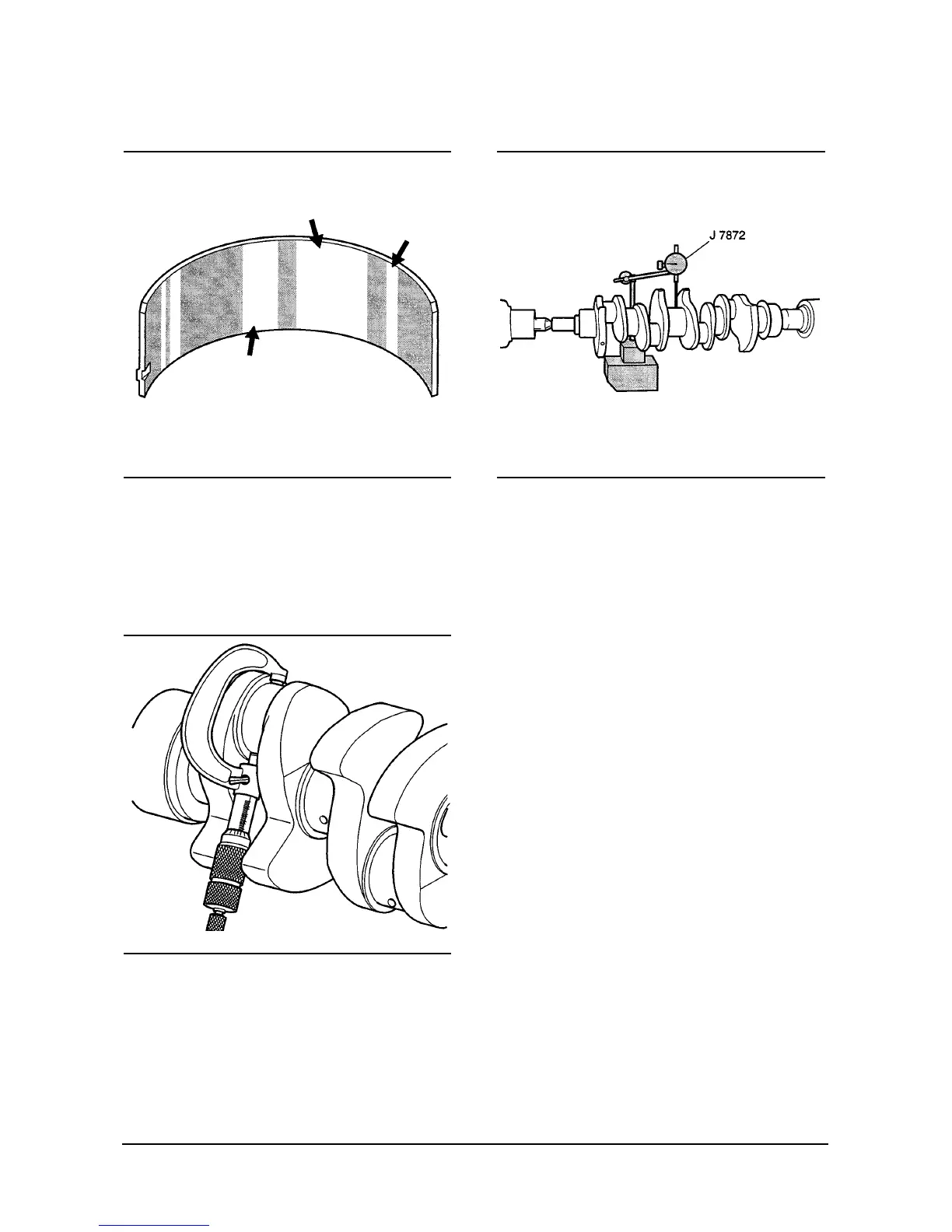

10. Support the crankshaft front and rear journals on

V-blocks.

11. Measure the crankshaft run-out at front and rear

intermediate journals with J 7872. Refer to Engine

Mechanical Specifications.

12. Replace or recondition crankshaft if measurements

are not within specifications.

VE050-3L

VE049-3L

VE048-3L

Loading...

Loading...