- 140 -

LP Engine G430(3.0L) Base Engine Service Procedure

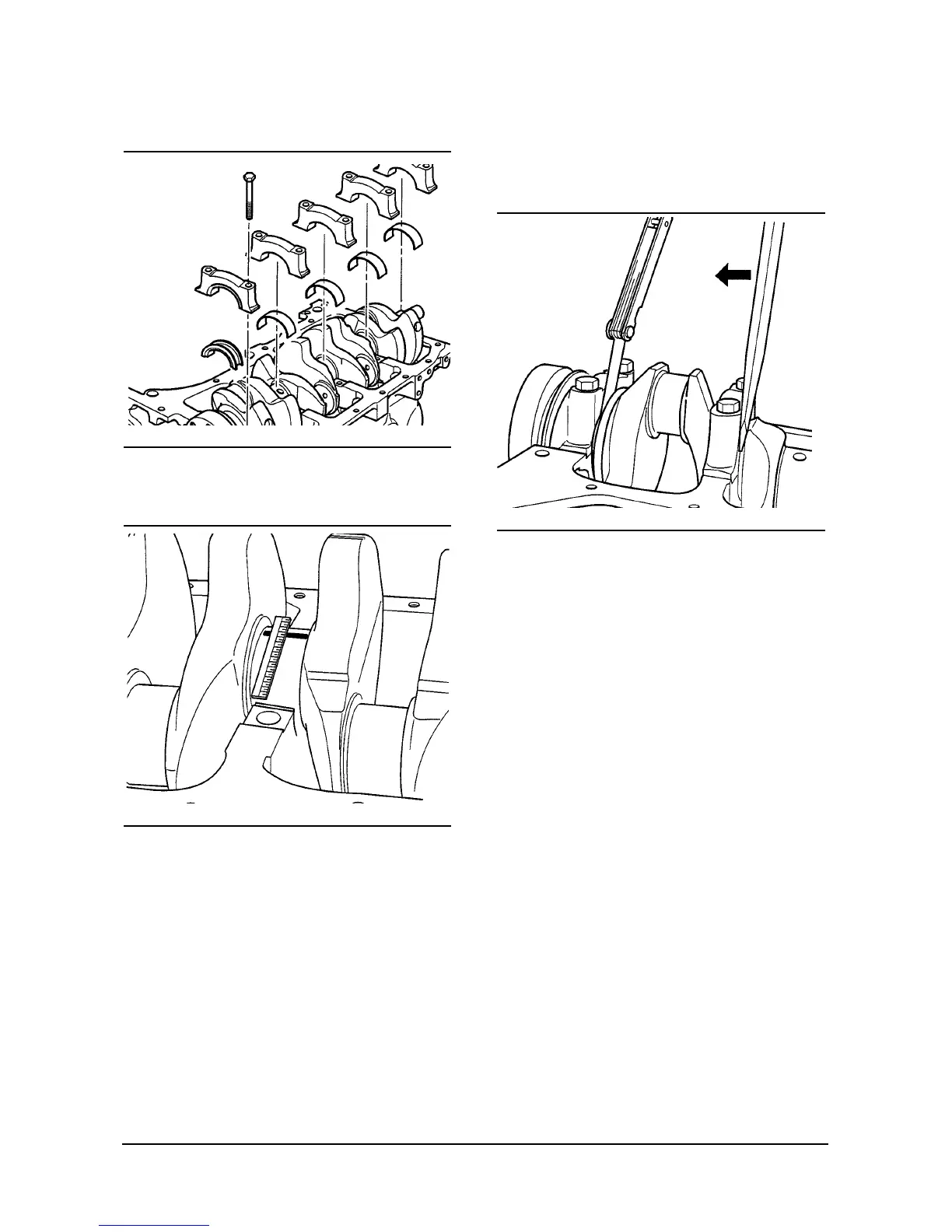

5. Remove the crankshaft bearing cap bolts.

6. Remove the crankshaft bearing caps.

7. Measure the gauging plastic at its widest area using

the scale supplied with the plastic gauging kit.

8. Compare the measurements to Engine Mechanical

Specifications.

• If the gauging plastic shows irregularity in the

journal exceeding 0.025 mm (0.001 in), remove

the crankshaft and measure the journal with a

micrometer.

• If the clearance is greater than Engine Mechanical

Specifications, select and install an undersized

bearing set. Measure the clearance with gauging

plastic.

• If clearance cannot be brought to specifications,

grind the crankshaft for use with the next

undersized bearing.

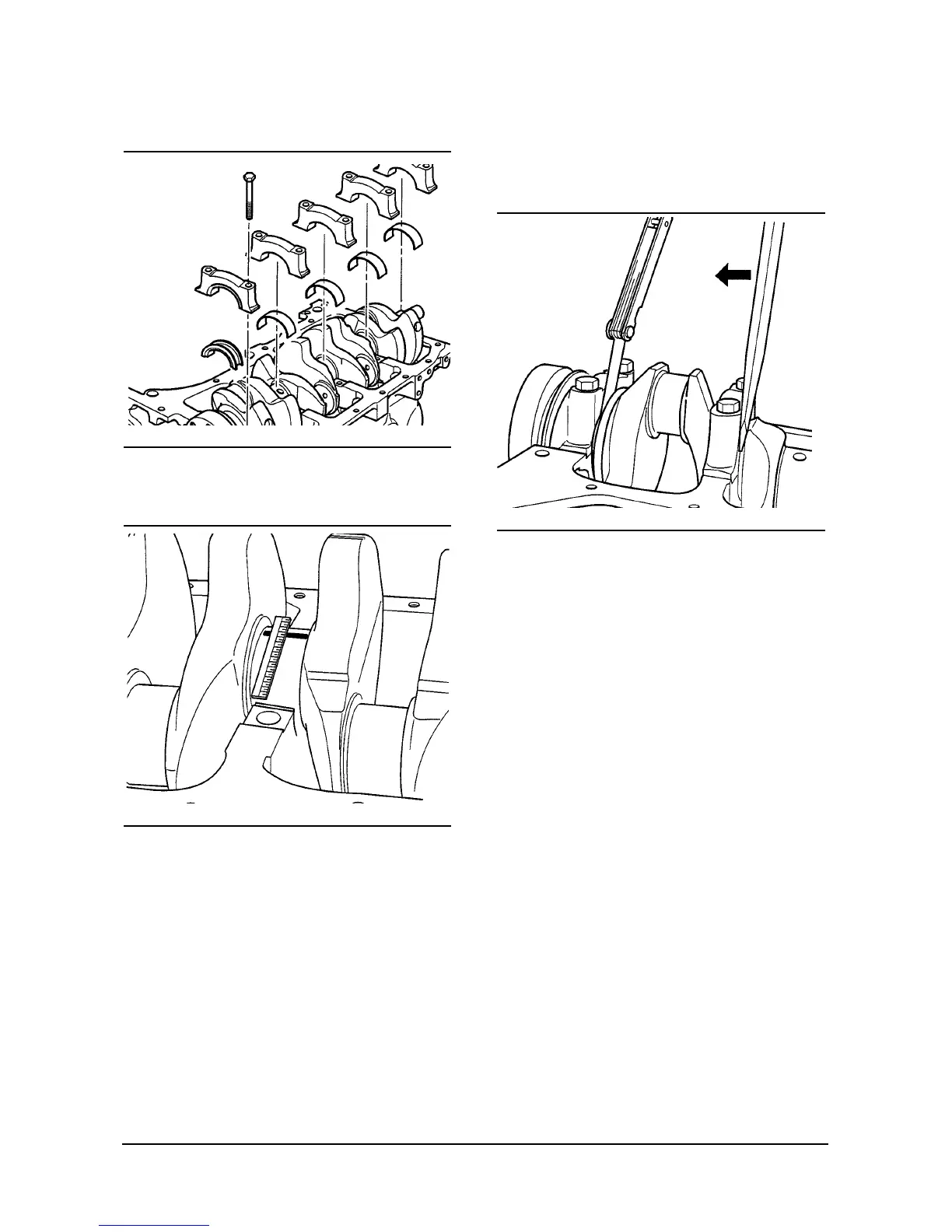

9. Use a dial indicator or feeler gauge in order to

measure end play between the front of the rear of

the crankshaft bearing cap and the crankshaft

thrust surface in order to determine the crankshaft

end play.

10. If you use a feeler gauge, measure between the

thrust surface of the crankshaft bearing and the

crankshaft.

Refer to Engine Mechanical Specifications.

VE053-3L

VE052-3L

VE045-3L

Loading...

Loading...