DOOSAN SERVO

11

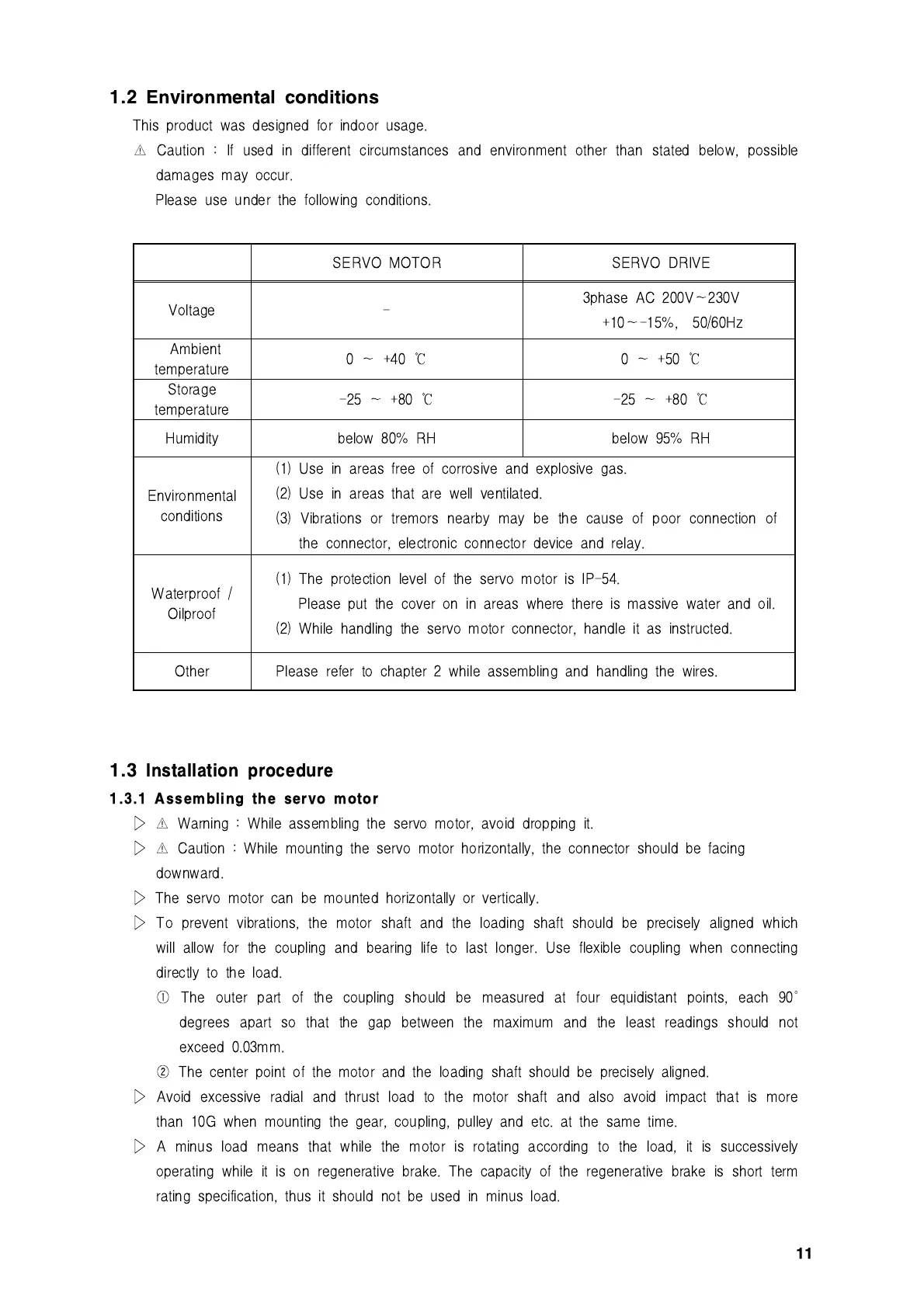

1.2 Environmental conditions

This product was designed for indoor usage.

Caution : If used in different circumstances and environment other than stated below, possible

damages may occur.

Please use under the following conditions.

(1) Use in areas free of corrosive and explosive gas.

(2) Use in areas that are well ventilated.

(3) Vibrations or tremors nearby may be the cause of poor connection of

the connector, electronic connector device and relay.

(1) The protection level of the servo motor is IP-54.

Please put the cover on in areas where there is massive water and oil.

(2) While handling the servo motor connector, handle it as instructed.

1.3

Installation procedure

1.3.1 Assembling the servo motor

▷

Warning : While assembling the servo motor, avoid dropping it.

▷

Caution : While mounting the servo motor horizontally, the connector should be facing

downward.

▷

The servo motor can be mounted horizontally or vertically.

▷

To prevent vibrations, the motor shaft and the loading shaft should be precisely aligned which

will allow for the coupling and bearing life to last longer. Use flexible coupling when connecting

directly to the load.

① The outer part of the coupling should be measured at four equidistant points, each 90

˚

degrees apart so that the gap between the maximum and the least readings should not

exceed 0.03mm.

② The center point of the motor and the loading shaft should be precisely aligned.

▷

Avoid excessive radial and thrust load to the motor shaft and also avoid impact that is more

than 10G when mounting the gear, coupling, pulley and etc. at the same time.

▷

A minus load means that while the motor is rotating according to the load, it is successively

operating while it is on regenerative brake. The capacity of the regenerative brake is short term

rating specification, thus it should not be used in minus load.

Loading...

Loading...