19

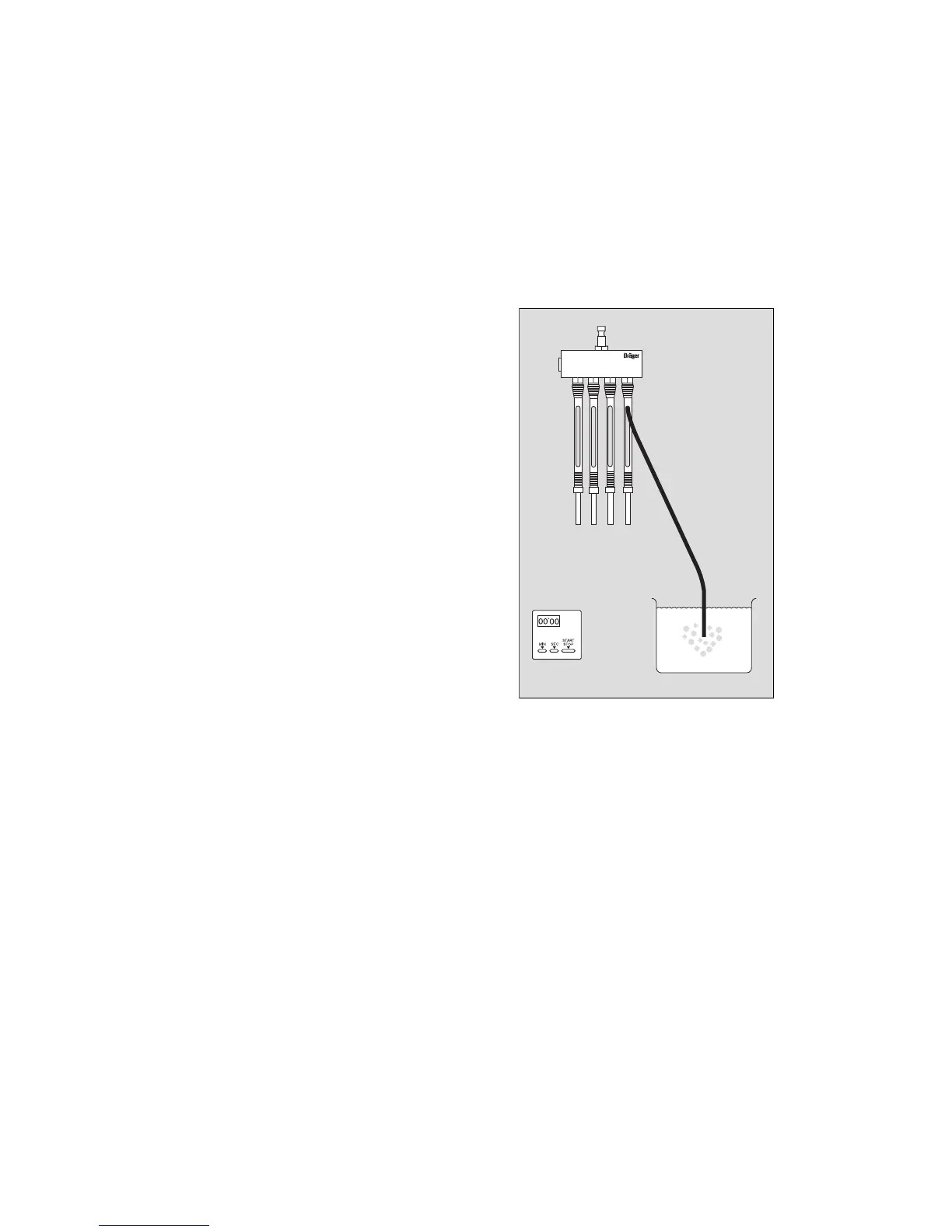

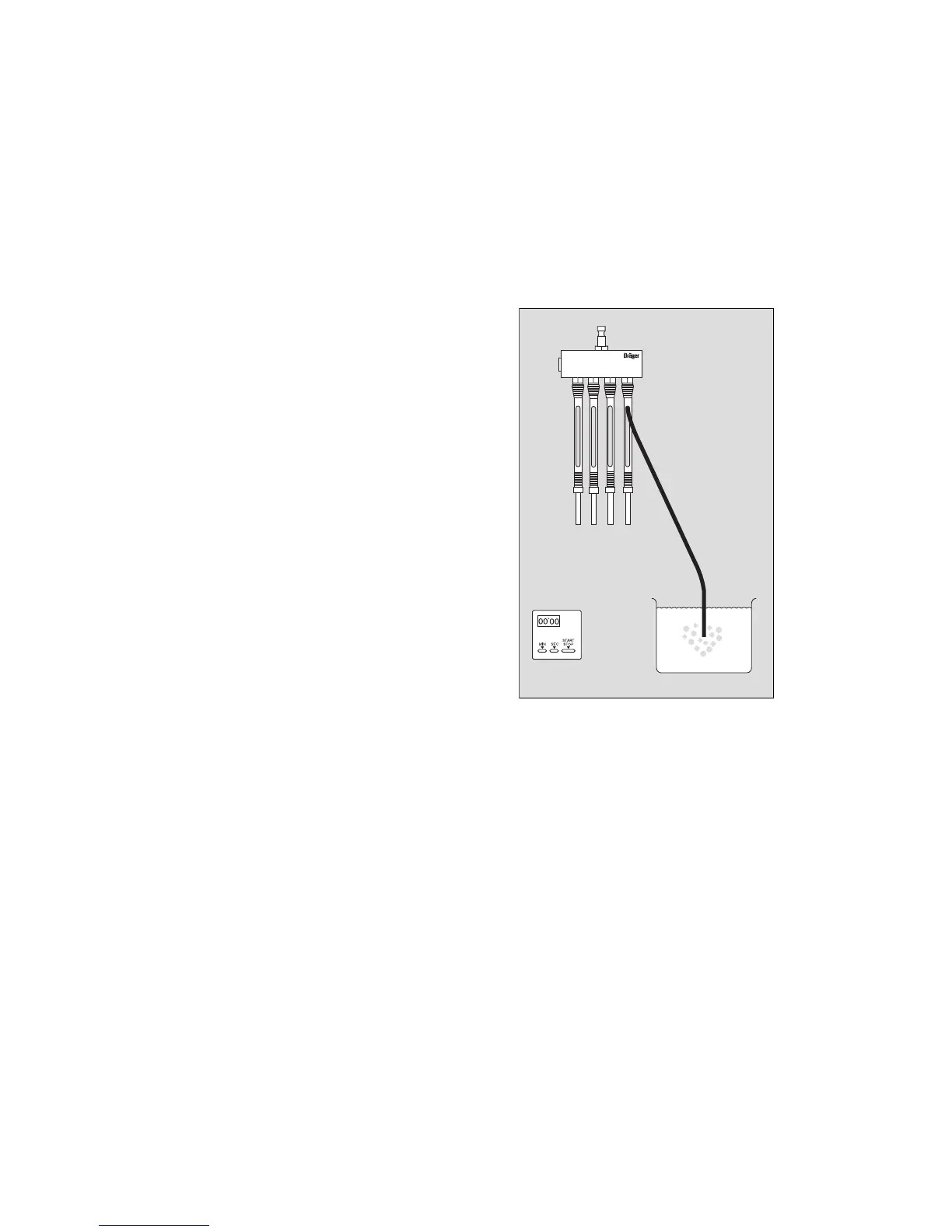

Bubble Test

The bubble test is used for the control of the measuring unit, see

“Maintenance Intervals” on page 24. It is tested whether volumetric

flow rate is guaranteed within the measure or a pollution and/or blok-

kage is available.

1 To this is the delivered bubble test hose plugged into the to be te-

sted connection of the measuring unit.

2 The other end of the bubble test hose is dipped into a water filled

receptacle.

3 With assistance of the timer, the ascending bubbles are counted:

CO

2

and CO connection, countable blistering

(e.g. 40 blow in 15 sec.).

Oil and H

2

O connection, large blistering (not countable).

Storage

Store all parts dry, free of deformation, in a cool and dust-free place.

Protect against direct light and heat sources.

Strictly follow the “Guidelines for the storage, maintenance and

cleaning of rubber products“.

00221437.e

s

Oil CO H

2

OCO

2

1

2

3

Loading...

Loading...