3

RZ50e

Rev. 3

April 2005

Testing

Before starting up for the first time and whenever

the apparatus has been serviced.

Testing the BG 4 with built-in CO2 absorber:

The function test can be carried out four times

during the one-year storage period. The tests

should not take longer than 15 minutes each. They

must be noted on the housing of the CO

2 absorber

with indication of the month and year and initialled

by the tester.

If the breathing circuit is opened for more than 5

minutes in exceptional cases, the ports of the CO

2

absorber must be hermetically sealed with the three

polyethylene plugs.

Test equipment and accessories

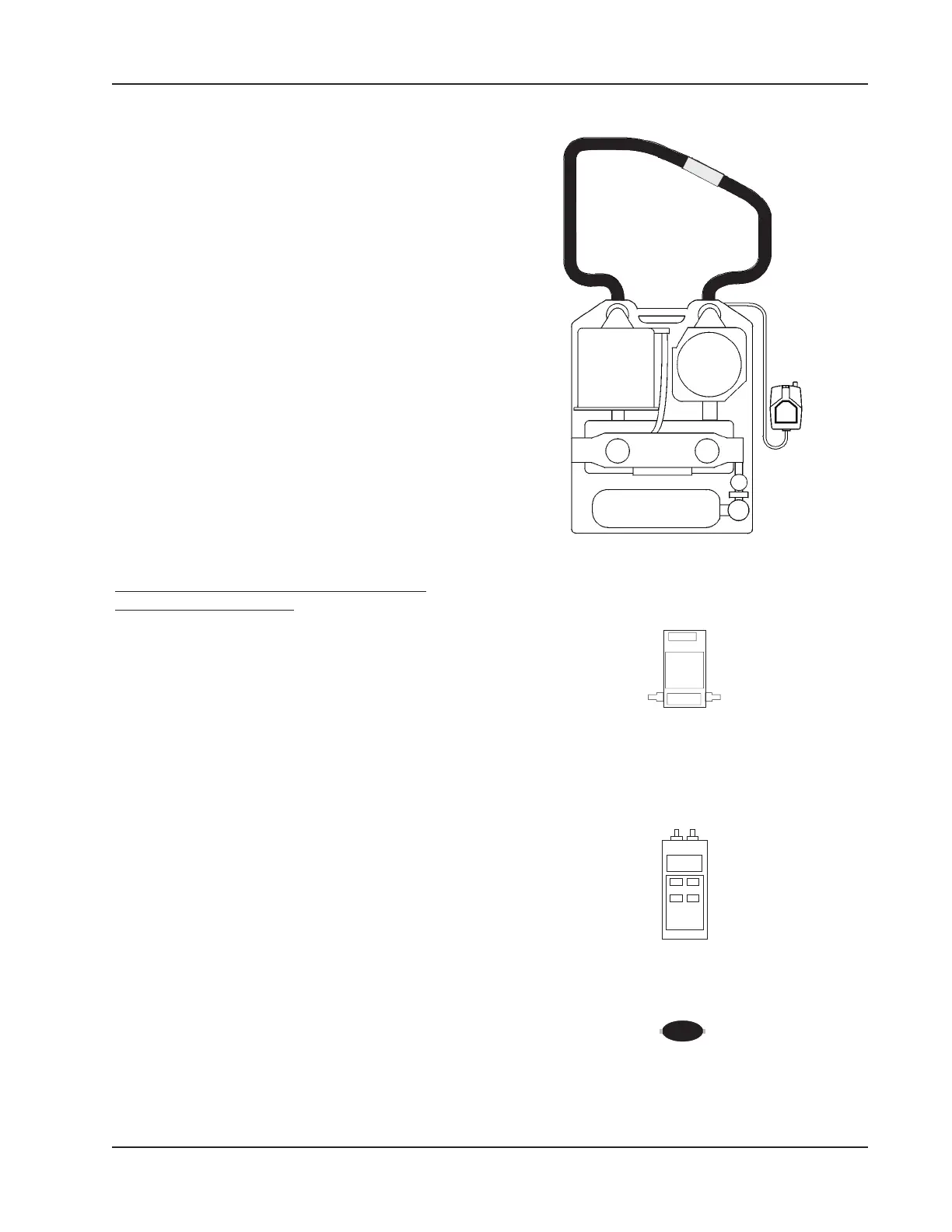

Test unit RZ50e

Sealing cap R 22 086

Additional test equipment by Dräger:

Quaestor E 12 490

Preparing for Tests

Ensure flow meter is powered and allowed to

stabilize to display ± 0.02

Align zero point of Flow Meter if necessary.

Pressure Gauge Preparation

• Connect battery to digital pressure gauge.

• Apply power to gauge, ensure gauge mode is set

to “mbar”.

• Depress “zero” button if display does not read

0.00mbar.

Tubing Connection

• Connect the small clear tubing to the left input of

the electronic pressure gauge.

• Connect the tubing with the clamp to the squeeze

bulb (positive side).

• Connect the female test adapter to the remaining

tube.

System Leak Test

• Adjust bulb flow restrictor closed (clockwise).

• Crimp tube end connected to female adapter.

• Apply positive pressure > 10 mbar.

• Close tube restrictor.

• Observe pressure gauge does not drop to zero

within 15 seconds.

Flow Meter

Pressure Gauge

Squeeze Bulb

(white band is negative)

Draeger Training 11/16 rev 1

Loading...

Loading...