16 Dräger PSS BG 4 plus

Maintenance

4 Maintenance

Maintenance is carried out in the following order:

1. Disassemble the closed-circuit breathing apparatus and

replace faulty parts (see chapter 4.2 on page 17).

2. Clean, disinfect and dry the closed-circuit breathing

apparatus (see chapter 4.3 on page 20).

3. Assemble the closed-circuit breathing apparatus

(see chapter 4.4 on page 21).

4. Test the closed-circuit breathing apparatus (see chapter 4.5

on page 25).

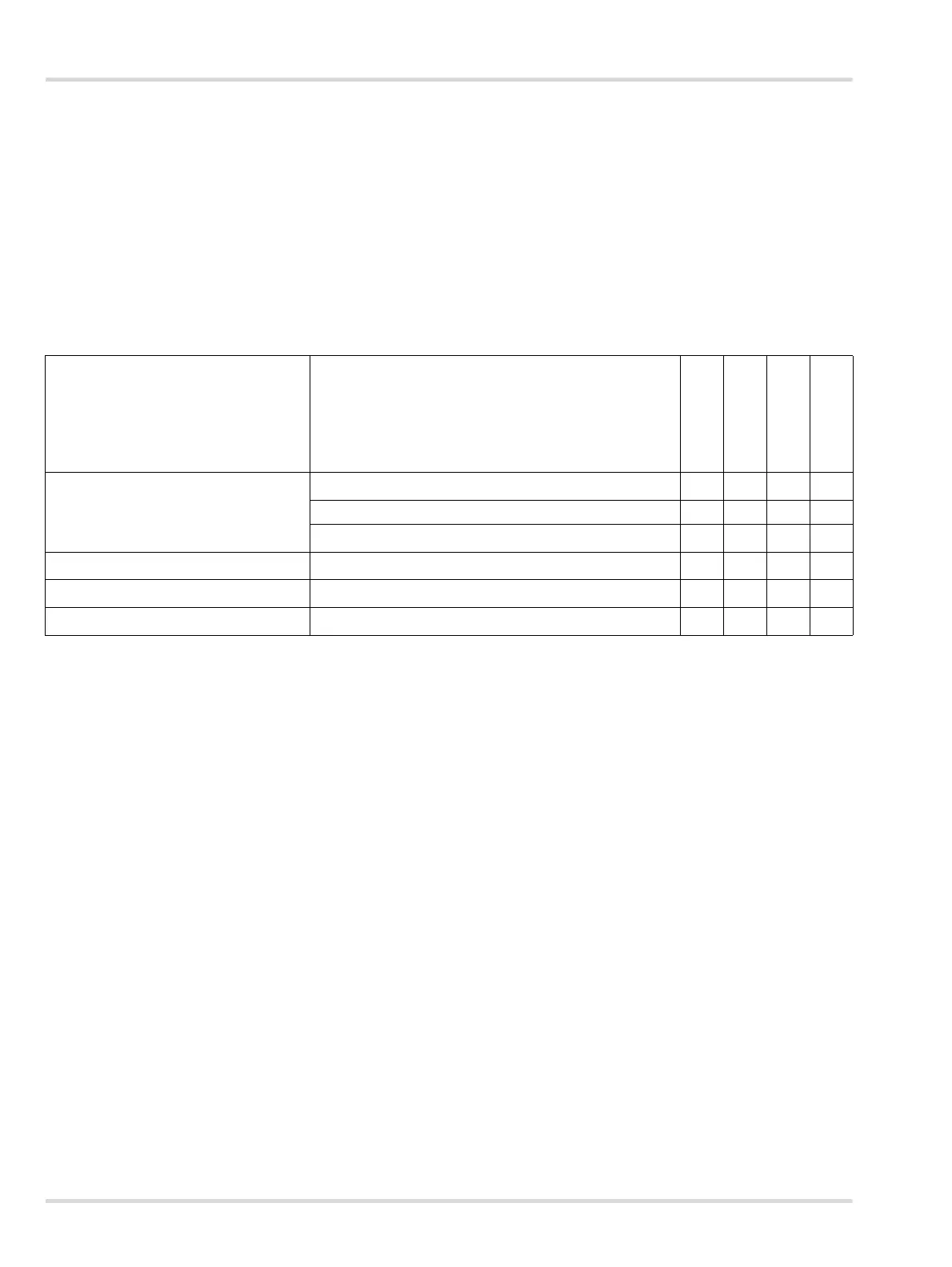

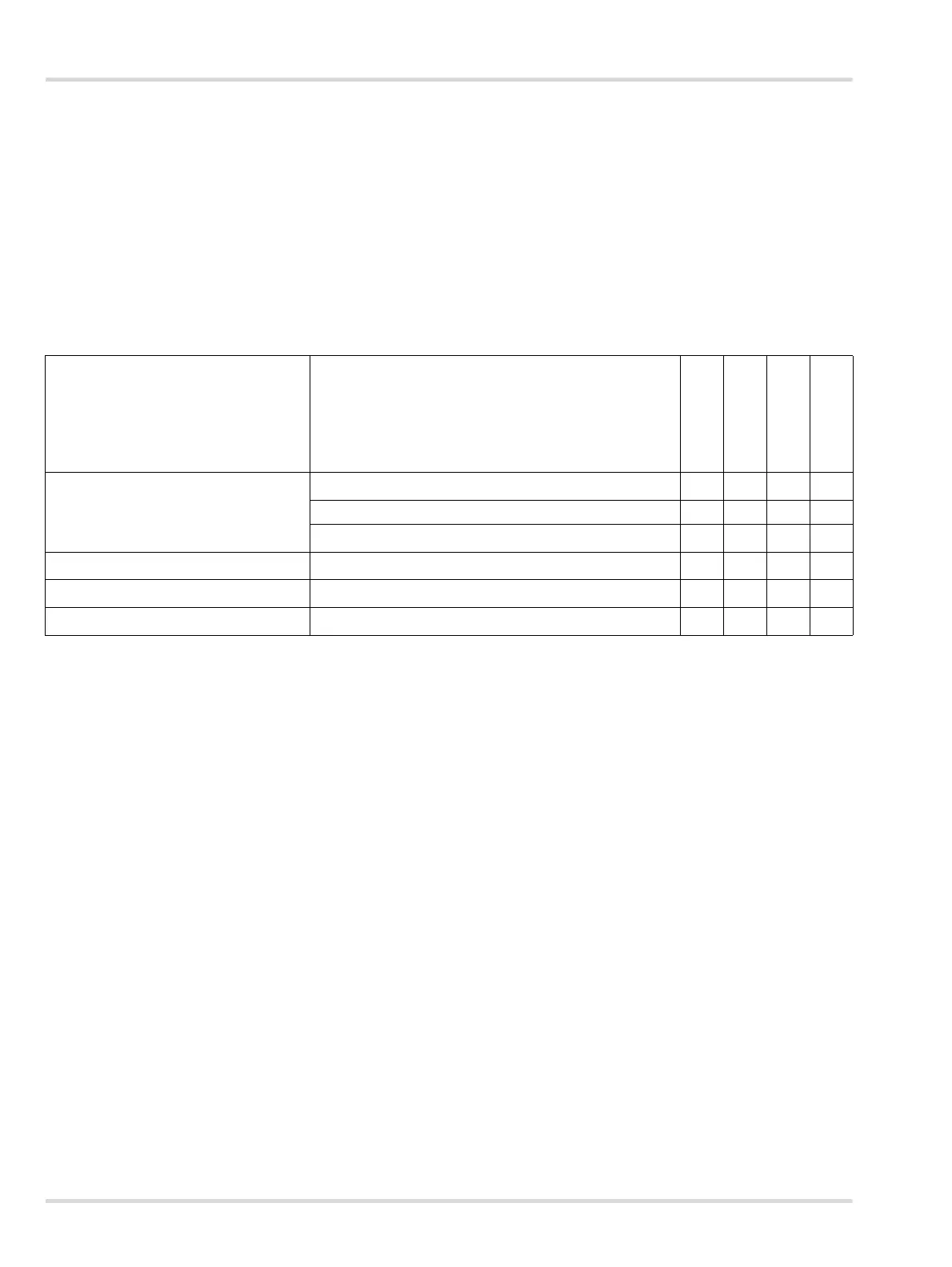

4.1 Maintenance intervals

Component Work to do

Every 6 months

Annually

Every 5 years

Every 6 years

Closed-circuit breathing apparatus Visual inspection, test function and sealing

X

1

X

2

Clean and disinfect AFTER EVERY USE

Major overhaul

3

X

CO

2

absorber (disposable cartridge) Replace

X

4

CO

2

absorber (refillable cartridge) Refill

X

4

Compressed oxygen cylinder

U.S.DOT

5

X

6

1 Applies to closed-circuit breathing apparatus that is constantly in use

2 Applies to reserve stocks

3 Only performed by expert personnel. Send the pressure reducer to Dräger for major over

haul.

4 Applies to CO

2

absorbers in closed-circuit breathing apparatus that are stored on vehicles or in the depot, tested in accordance with

chapter 4.5 on page 25 and the connecting piece of which is sealed with the corresponding protective cap.

5 Hydro-testing in accordance with the local requirements.

6 Composite cylinder: Life cycle = 15 years from date of manufacture.

Draeger Training 11/16 rev 1

Loading...

Loading...