ww w.drilldoctor.com 17

Identifying Correctly Sharpened Drill Bits

(and what to do with those that aren’t!)

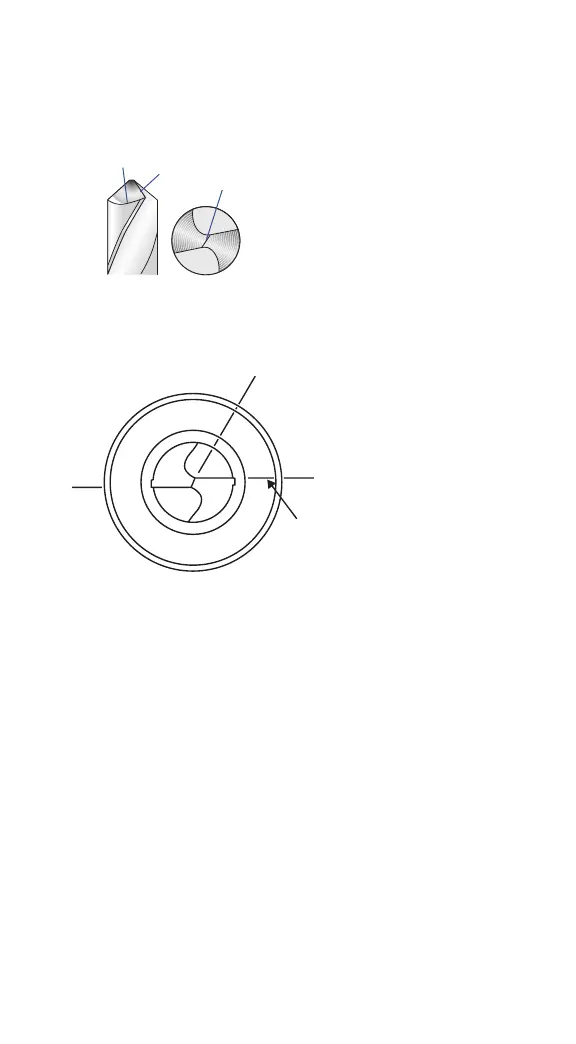

Correctly Sharpened Bits

The entire surface from the Cutting

Edge to the Heel will have a nely

ground surface without ridges or

indentations. The Heel will always be

lower than the Cutting Edge (positive

relief).

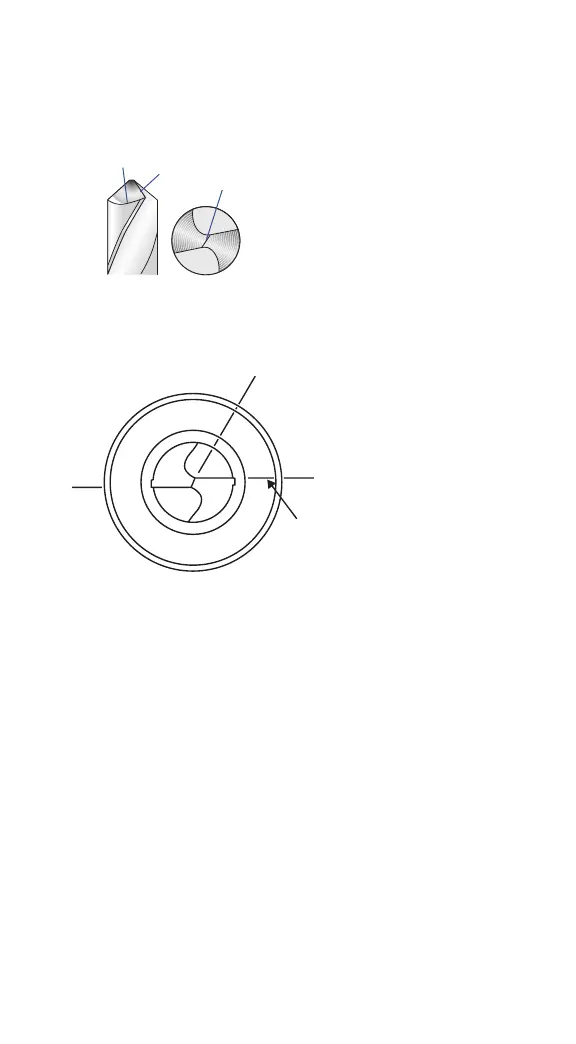

Once you have reached spark-out (no more grinding noise at all)

take a look at your drill bit. The chisel angle should be at 1 o’clock

or 1:30.

Heel

Cutting

Edge

Chisel

Point

3:00

1:00

scribe

line

Look at the bit: Hold

the bit up and look at it

with the cutting edges

in line with the horizon

(or parallel with the

9:00 and 3:00 position

imagining a clock’s

face).

2:00 is too far advanced,

and if the chisel gets too

close to 12:00, the relief

will be negative.

Too much relief will cause an oversized hole diameter and rapid

bit wear. Too little relief will limit feed rates, slowing down the

drilling operation or in extreme cases cause the drill not to

perform at all.

If chisel angle looks to be about 2 o’clock, align bit 1-2 ticks on

the minus direction.

If chisel angle is up to about 2:30, align 2-3 ticks minus.

If chisel is about 12:45, it’s at the low end of chisel and relief,

align 1 tick to positive.

Loading...

Loading...