3

1. INTRODUCTION

This operation and maintenance manual refers to the Bravo lubrication pump, and includes essential information

regarding correct operating and safety procedures design to ensure safe and reliable operation of the unit.

You can obtain the latest release of this document by contacting a Dropsa sales office or distributor or by visiting us on the

World Wide Web at http://www.dropsa.com.

It is important that this document is read and maintained in a place that anyone operating the Bravo is able to consult it if

necessary.

2. GENERAL DESCRIPTION

2.1 CENTRALIZED LUBRICATION – GENERAL OPERATING INFORMATION

Centralized lubrication systems are designed to provide oil or grease for lubricating fiction points on industrial and mobile

machinery. Such systems considerably reduce the cost of maintaining machinery on which they are installed, eliminating

machinery downtime caused by poor lubrication as well as prolonging the life of the machinery in general. Additionally, a

centralized lubrication system allows difficult to reach lubrication points to be

lubricated at frequent intervals that would otherwise be hard to access under normal

conditions.

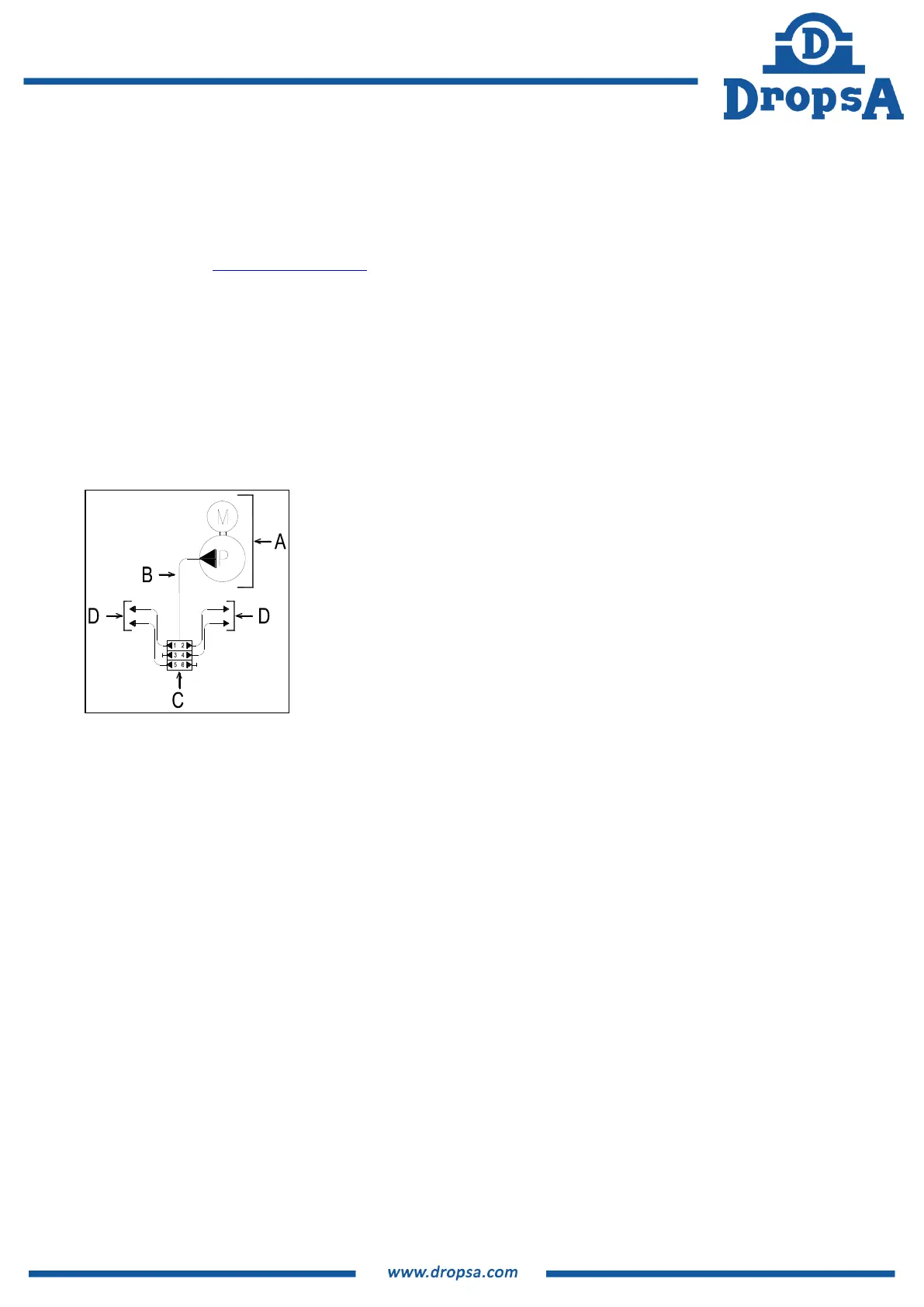

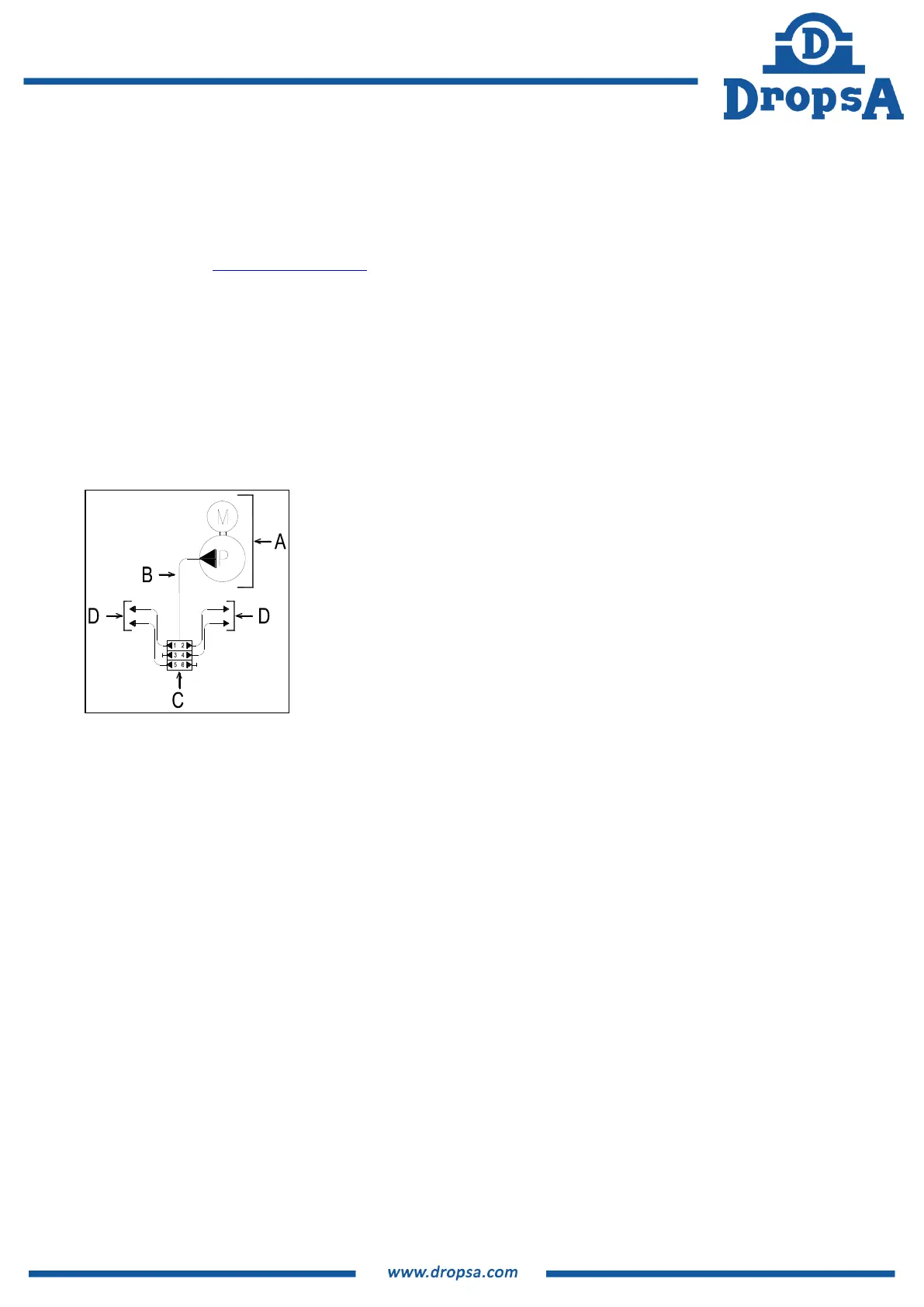

The diagram on the left shows a typical schematic of a simple centralized lubrication

system.

The main components are:

A – Electric Pump with Reservoir (eg. Bravo Pump).

B – Primary lubrication line for distributing grease.

C – Distributor elements that meters grease into a number of points.

D – Secondary tubing that delivers grease to the lube point.

The pump feeds a distributor element that shares and doses the ratio of grease between the several friction points.

Bravo Pump has been designed to provide the pumping solution for such systems used in industrial and mobile

applications for greases up to NLGI 2 consistency and Oils with minimum 46cSt.

2.2 BRAVO ELECTRIC GREASE PUMP

BRAVO is an electric piston pump with the pumping element operated from a camshaft connected to a reducing gearbox.

It can be fitting with up to 3 pumping elements (1 standard) which are available with or without an integrate pre-set

bypass (pressure safety valve).

The Bravo also has a modular build reservoir that can be supplied in 2, 5, 8 litre capacity. Additionally a minimum level

sensing device is fitted as standard at the base of the unit. As an optional accessory, a remote button with light is

available.

Bravo is available as both with an integrated automatic control board that controls and monitors the pump and lubrication

cycle or a manual version where the pump motor is controller externally by applying and removing power.

The main body of the pump is made from high performance robust plastic and is compact in size designed to withstand

tough environments.

The grease version of the Bravo includes a stirrer device with a reservoir wiper that help to eliminate air present in the

grease and facilitate pumping even at lower temperatures.

The direct-current geared motor drive arrangement, is controlled remotely in the manual version or via the built in control

system in the automatic version. There are three operating modes for the controller version. (Refer to 5.1 paragraph)

3. PRODUCT IDENTIFICATION

On the side of the pump there is a label that indicates part number of the product, operating voltage and basic

characteristics.

Loading...

Loading...