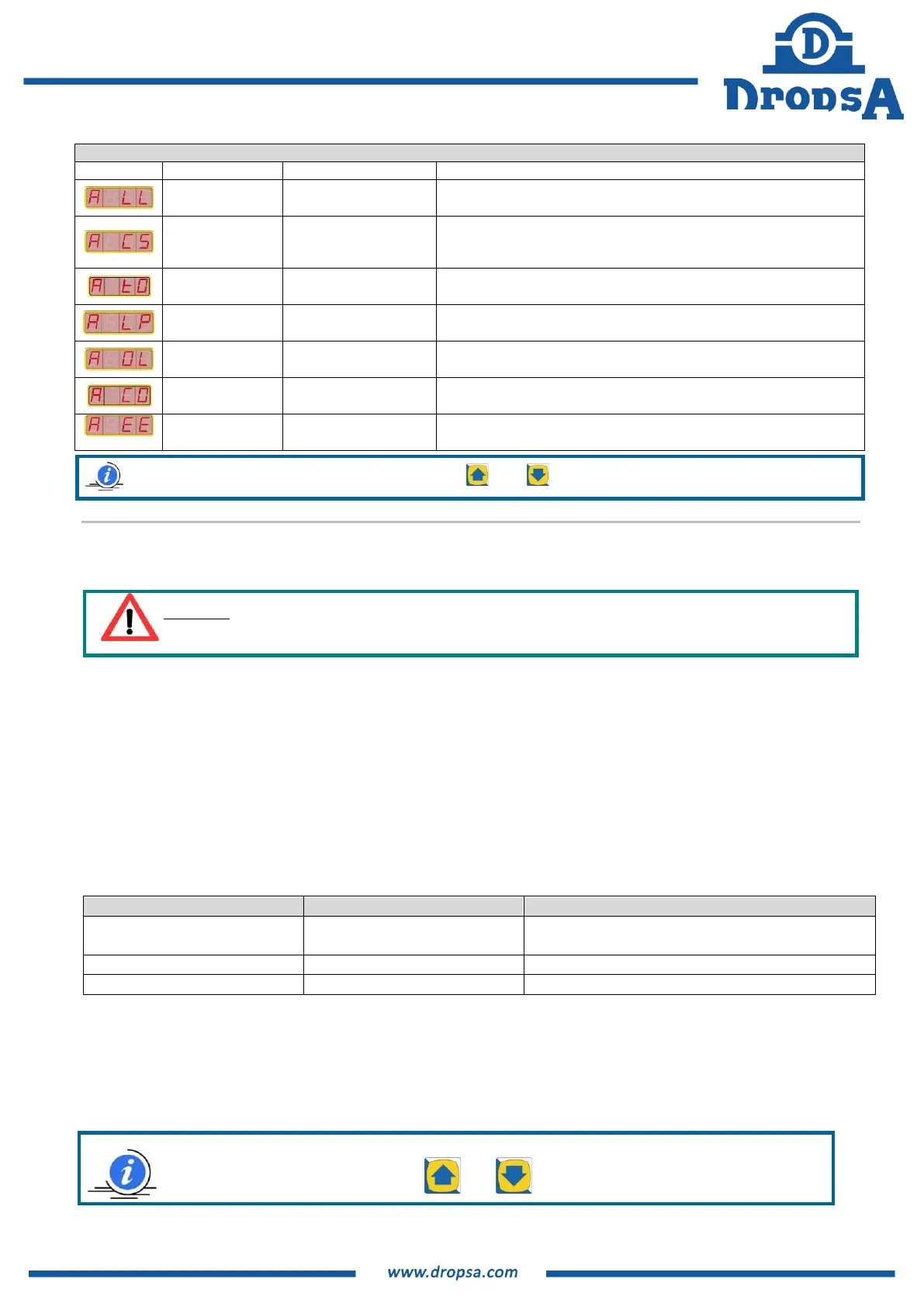

18

Low lubricant level in

reservoir

Refill with clean lubricant.

The cycle sensor was not received within the specified time. Ensure

Timer overlong is set to approriate value and that there is no problem

on the lubrication circuit.

Verify input pause sensor

Allow system to cool, if the problem still goes on go on, replace the

motor unit.

C.COU pulses counter in

Pulse Mode

Electronic Board memory error. Board requires replacement.

9. MAINTENANCE PROCEDURE

The Bravo pump does not necessitate any special tool for operation and maintenance. When working with the Bravo

pump it is nonetheless recommended that personal health and safety equipment is used as is normal for any operation in

an industrial or similar workplace to best safeguard the user from harm.

The Bravo pump has been designed and built as to require minimal maintenance and operate in diverse and challenging

operating environment. It is recommend that the unit is inspected and kept clean to ensure long life and trouble free

operation. It is important to check all tubing on the system to ensure that it is always tight and leak free.

9.1 Programmed and operational Maintenance

The following operations should be performed on the pump.

Integrity of tubing and system

After initial 500 hours.

Every1500 hours.

Check fittings and tubing secured.

Verify components are correctly fixed to machine.

Top up level with clean lubricant.

As needed, or once per year.

Check and replace as necessary.

10. DISPOSAL

During maintenance or disposal of the machine care should be taken to properly dispose of environmentally sensitive

items such as oils or other lubricants. Refer to local regulations in force in your area. When disposing of this unit,it is

important to ensure that the identification label and all the other relative documents are also destroyed.

NOTE: To cancel alarm message push buttons and together

NOTE:

To cancel an error message press and .

WARNING: Before carrying out any maintenance operation, ensure that power and hydraulic system are

disconnected.

Loading...

Loading...