5.3 Lower thread

Look out! Danger of injury!

Turn off main switch!

The l ower thread may only be threaded with the sewing

machine switched off.

Threading the lower thread (hook thread)

–

Place the thread spool on its column.

–

Pass the lower thread through the thread guide on the take-up arm and alternately

through the guide of the pre-tensioner 1.

–

Pass the thread anti-clockwise round tensioner 1 and once more through the thread

guide.

–

Carefully wind a few turns of thread anti-clockwise onto the spool by hand and

place the spool on its column.

–

Swivel the bobbin winder 4 against the empty s pool.

The thread is wound onto the spool during sewing.

When spool 3 is full, winding-on is halted by the bobbin-winder lever 4.

–

Adjusting tension 1.

The thread should be wound on at minimum tension.

Threading the lower thread

–

Raise flap 5 and remove the empty spool with a magnet or tweezers.

–

Insert spool 6 in such a way that when the thread is unwound from it moves in the

opposite direction to the hook.

–

Pass the thread through slit 7 and below spring 10.

–

Pass the thread through slit 8 and pull about 3 cm through.

–

Close flap 5 and pass the thread through the flap’s guide 9.

Adjusting the lower-thread tension

The lower-thread tension should be s et in accordance with the type of seam required.

Adjust the tension with screw 11.

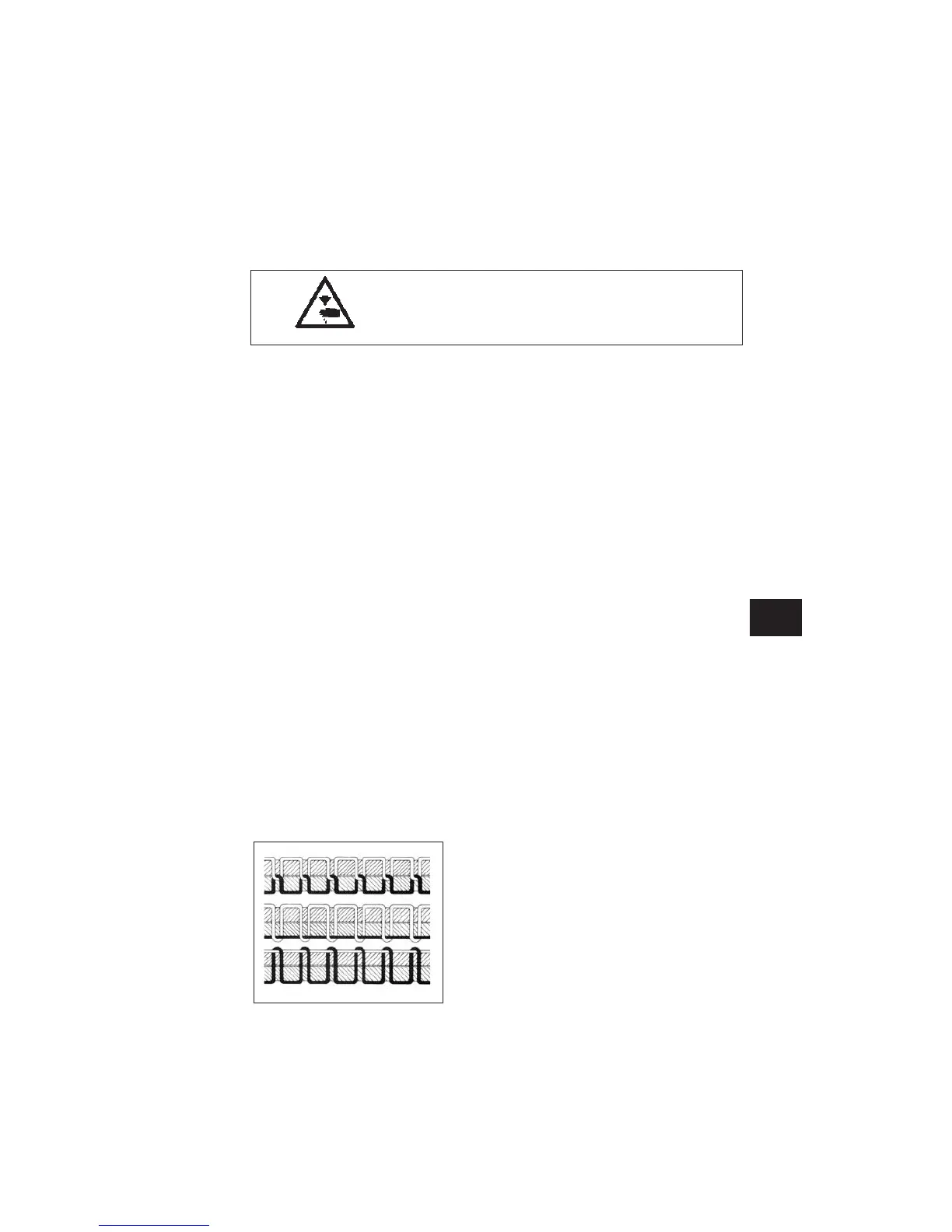

Fig. a: correct thread interlacing in the centre of

the material

Fig. b: needle-thread tension too low

or looper-thread tension too great

Fig. c: needle-thread tension too great

or looper-thread tension too low

13

GB

Loading...

Loading...