27CC 222/222C - CC 232/232C - CC 322 M222EN5

Regular inspection and maintenance are necessary to

ensure satisfactory long-term operation.

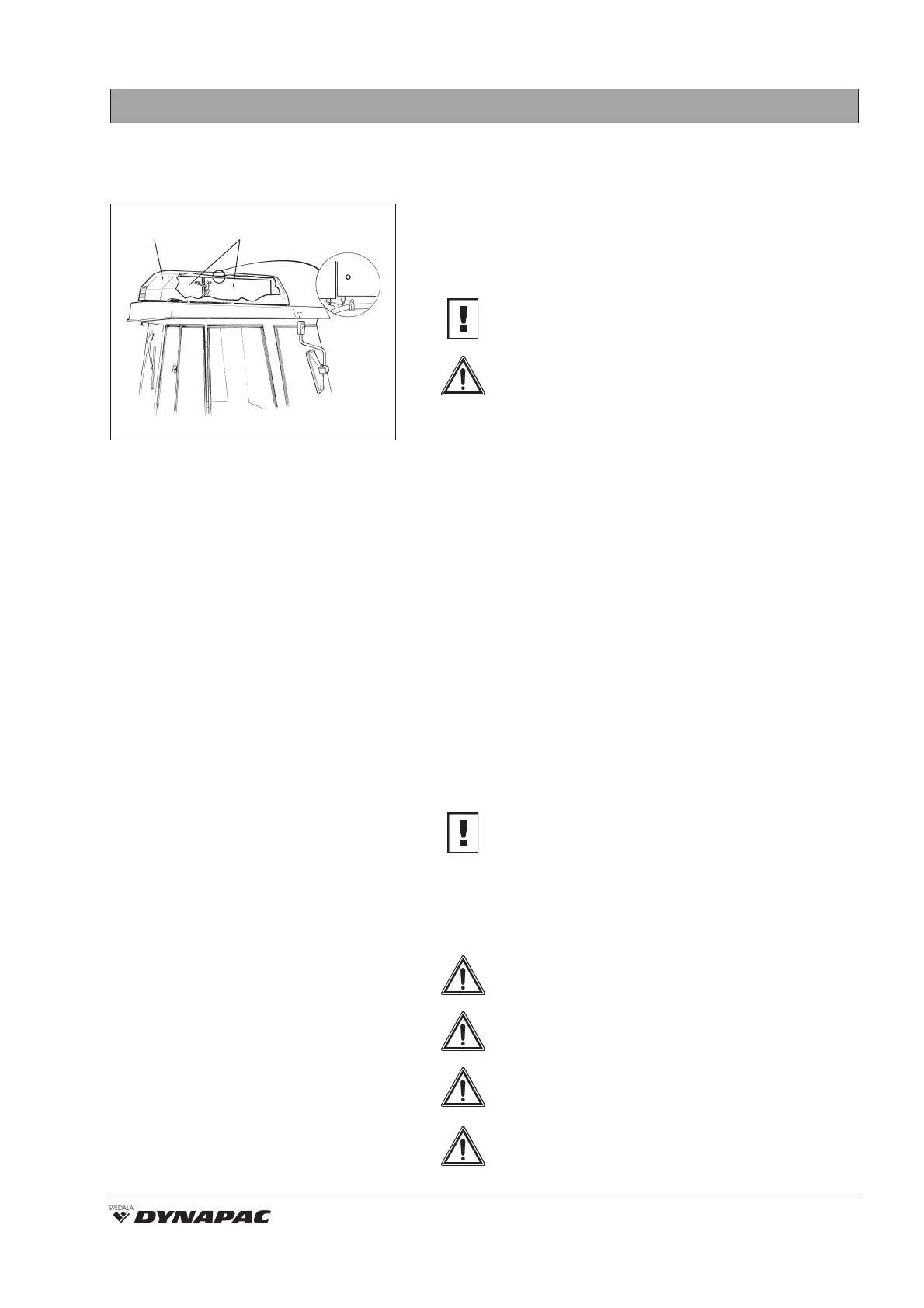

Lift off the fiberglass cover (1) and then screw loose the

two covers (2) from the unit.

Clean the condenser unit and the condenser elements

free from dust using compressed air.

The air jet could damage the flanges of the

elements if it is too powerful.

Wear protective goggles when working

with compressed air.

Inspect the fastening of the condenser element.

Clean the cooler unit and the cooling elements free from

dust using compressed air.

Inspect and shield the system’s hoses against chafing.

Inspect the fastening of the compressor motor and

hydraulic motor, and also the clearance of connecting

collars between the compressor and the hydraulic

motor. The axial clearance should be about 4–5 mm

(0.16-0.20 in) and the radial clearance about 1 mm (0.04 in).

Make sure that drainage from the cooling unit is unob-

structed so that no condensation accumulates inside

the unit.

Inspect suspension of the rubber dampers for the con-

denser unit. Check that they are not cracked and show

no sign of damage.

The unit should be run at least five minutes every week,

if possible, to ensure lubrication of rubber gaskets in the

system.

The air unit should not be run when the outdoor

temperature is below 0°C (32°F).

Inspect the sight glass on the unit (1), above the dryer

filter in the condenser. Bubbles should only be visible on

starting and stopping the compressor. An authorized

service company should be consulted for service if

many bubbles or milky fluid are observed.

The compressor will be damaged if the unit

is run with too little refrigerant.

Do not disconnect the hose coupling.

The cooling system is pressurized.

Incorrect handling can result in serious

personal injuries.

The system contains pressurized refriger-

ant. Releasing refrigerants into the air is

prohibited. The refrigerant circuit may only

be repaired by an authorized company.

EVERY 2000 HOURS OF OPERATION (Yearly)

Fig. 49 Air conditioning

1. Fiberglass cover

2. Cover

3. Sight glass

3

12

Air conditioning (Optional) -

Overhaul

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

Loading...

Loading...