5CC 222/222C - CC 232/232C - CC 322 M222EN5

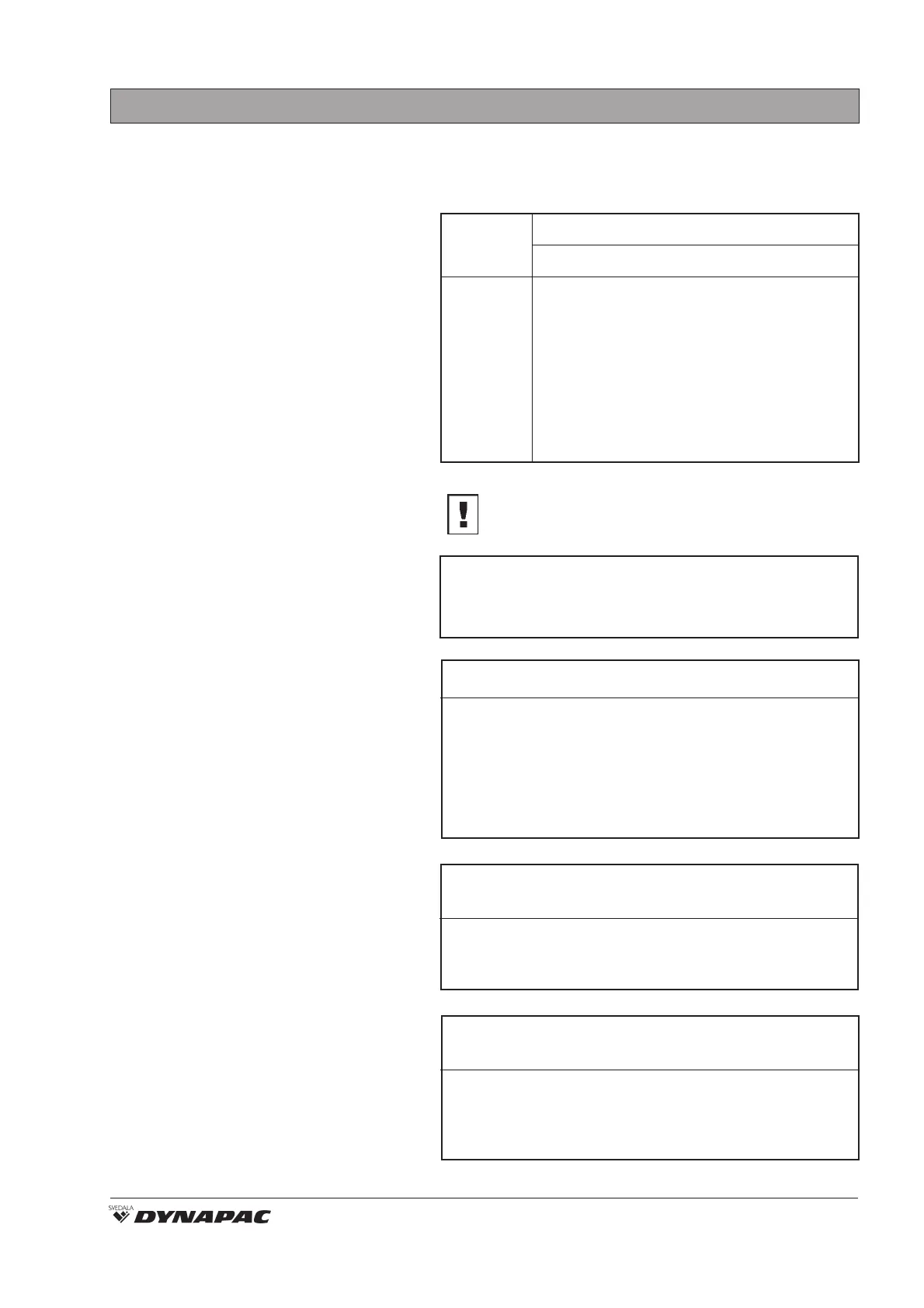

Opening pressure MPa CC 222/322 CC 232

Drive system 42,0 42,0

Supply system 2,0 2,0

Vibration system 35,0 35,0

Control systems 20,0 20,0

Brake release 1,5 1,5

TECHNICAL SPECIFICATIONS (contd.)

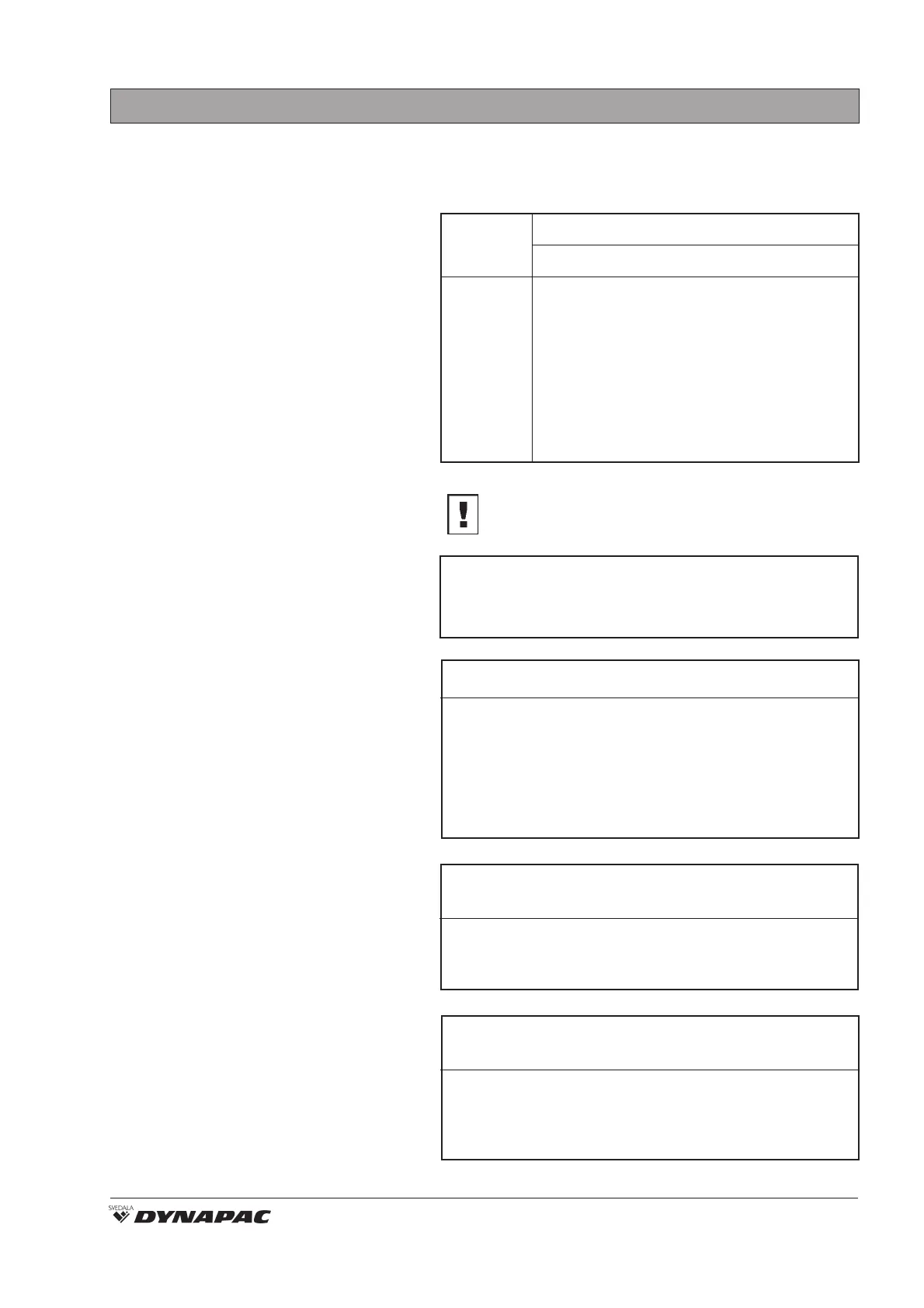

Tightening torque

M STRENGTH CLASS

thread 8.8 10.9 12.9

M6 8,4 (6.2) 12 (8.9) 14,6 (10.8)

M8 21 (15.5) 28 (20.7) 34 (21.1)

M10 40 (15.5) 56 (41.3) 68 (25.1)

M12 70 (51.6) 98 (72.3) 117 (86.3)

M16 169 (124.7) 240 (177) 290 (213.9)

M20 330 (243.4) 470 (346.7) 560 (413.1)

M24 570 (420.4) 800 (590.1) 960 (708.1)

M30 1130 (833.5) 1580 (1165.4) 1900 (1401.4)

M36 1960 (1445.7) 2800 (2065.3) –

Tightening torque in Nm (lbf.ft) for oiled, bright

galvanized bolts tightened with a torque wrench.

Hydraulic system

Bolt size: M24 (P/N 90 37 92)

Strength class: 10,9

Tightening torque: 800 Nm (Dacromet treated)

ROPS

Measured with vibration switched ON and on a

foam-rubber mat, standard roller

Vibration on the operator’s seat is 0,4 m/s

2

Vibration on the floor of the operator’s station is 0,2 m/s

2

The limit value is 0,5 m/s

2

Vibration - Operator’s station

(ISO 2631)

Always make sure the ROPS bolts are dry

before you torque-tighten them.

Noise level - Operator’s station

(ISO 6394)

Noise levels with vibration switched OFF (dBA)

Measured on hard surface, standard roller

Operator’s station, (with cab) LpA: 74 dB(A)

Operator’s station, (without cab) LpA: 84 dB(A)

Seven meters from the machine LpA: 73 dB(A)

CAUTION

Loading...

Loading...