15CC102/C/122/C/132/142/C M102EN4

2 3

14

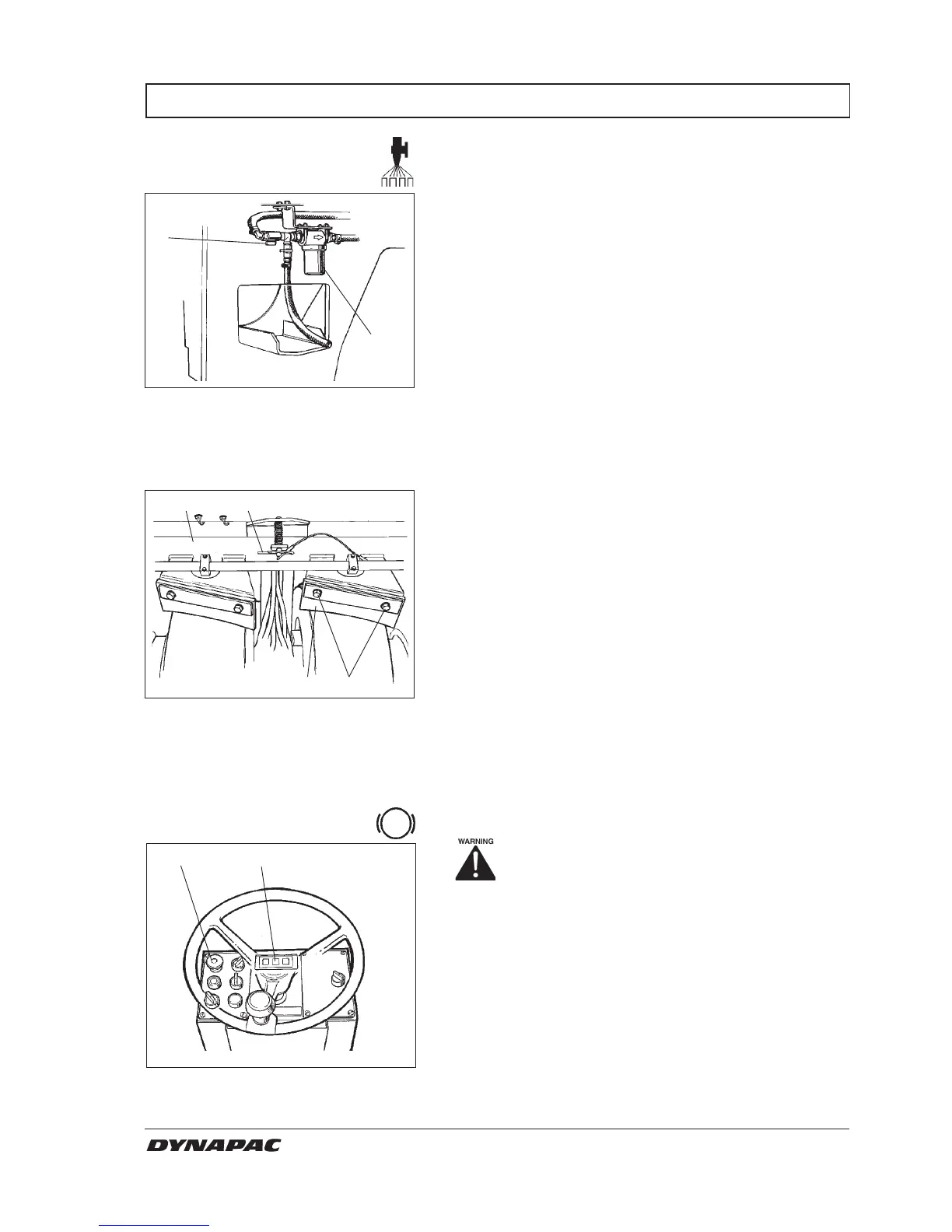

Scrapers – Checking – Setting

Fig. 15 Wheel scrapers

1. Scraper

2. Scraper beam

3. Cotter pin

4. Adjusting screws

Make sure that the scraper (1) lies against the tire

when compacting asphalt compounds.

The scrapers must hang freely from the tires during

transport driving. Lift up the scraper beam (2) by

moving up the cotter (3) to the uppermost hole.

To adjust the scraper’s angle of contact to the tire,

loosen the screws (4), set the scraper and then tighten

the screws.

Pump system/Tires

Checking – Cleaning

2

1

Fig. 14 Left step

1. Filter housing

2. Loader

When cleaning, close the stopcock (2). Release the

filter housing (1). Clean the insert and the filter housing.

Listen to or put your hand on the water pump to check

that it is working.

EVERY 10 HOURS OF OPERATION (Daily)

69

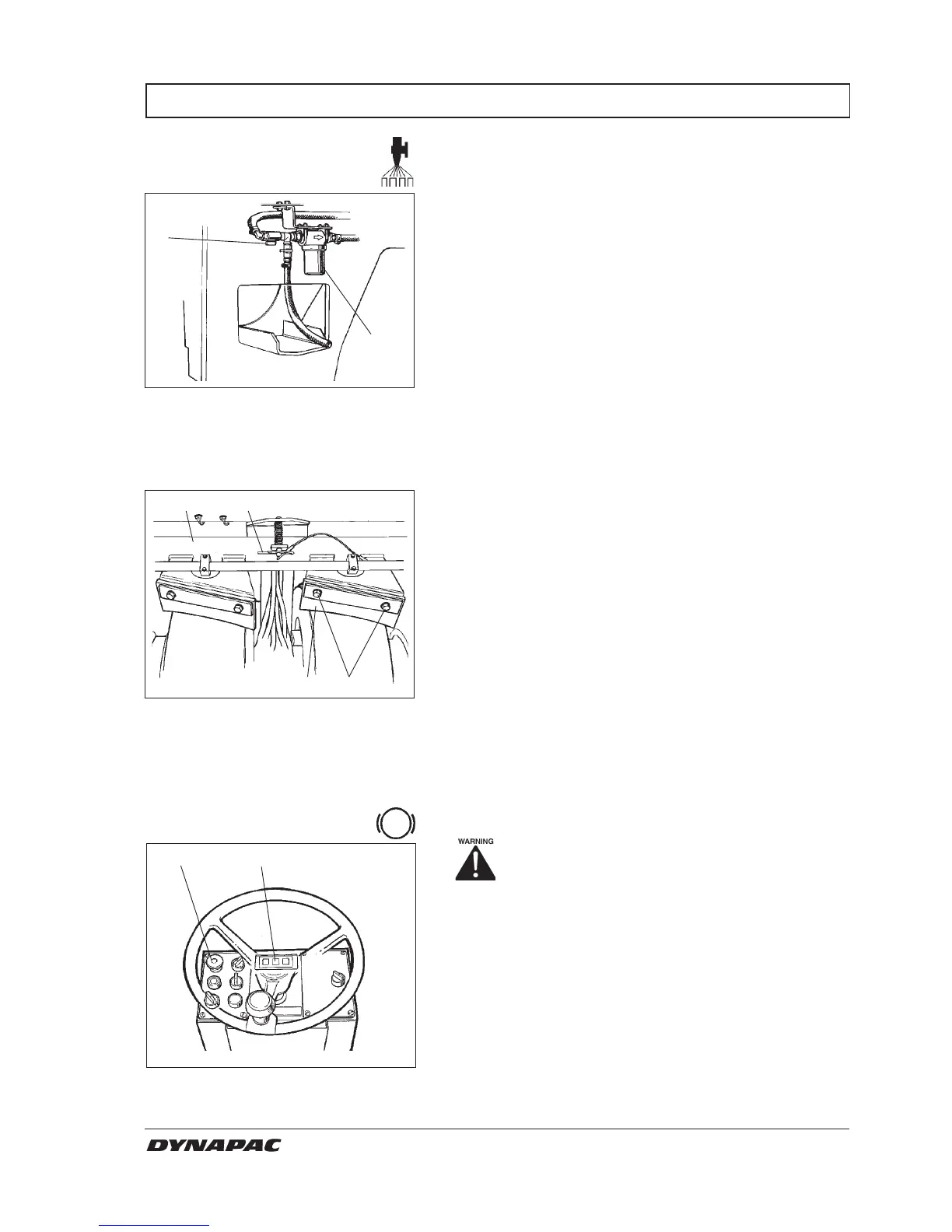

Fig. 16 Instrument panel

6. Reserve/parking brake knob

9. Brake warning lamp

Brakes – Check

Check operation of the brakes as follows:

Drive the roller slowly forward.

Push in the reserve/parking brake knob (6).

The brake warning lamp (9) on the instrument panel

should light and the roller should stop.

After testing the brakes, set the forward/reverse lever

in neutral.

Pull up the reserve/parking brake knob.

The roller is now ready for operation.

Loading...

Loading...