29CC102/C/122/C/132/142/C M102EN4

It is easiest to clean the tank when it is almost empty.

Pump out any bottom sediment with a suitable

pump, such as an oil emptying pump. Save

the oil in a can and deposit it in an approved

manner.

Remember the danger of fire when hand-

ling fuel.

The fuel tank is made of recyclable plastic

(polyethylene).

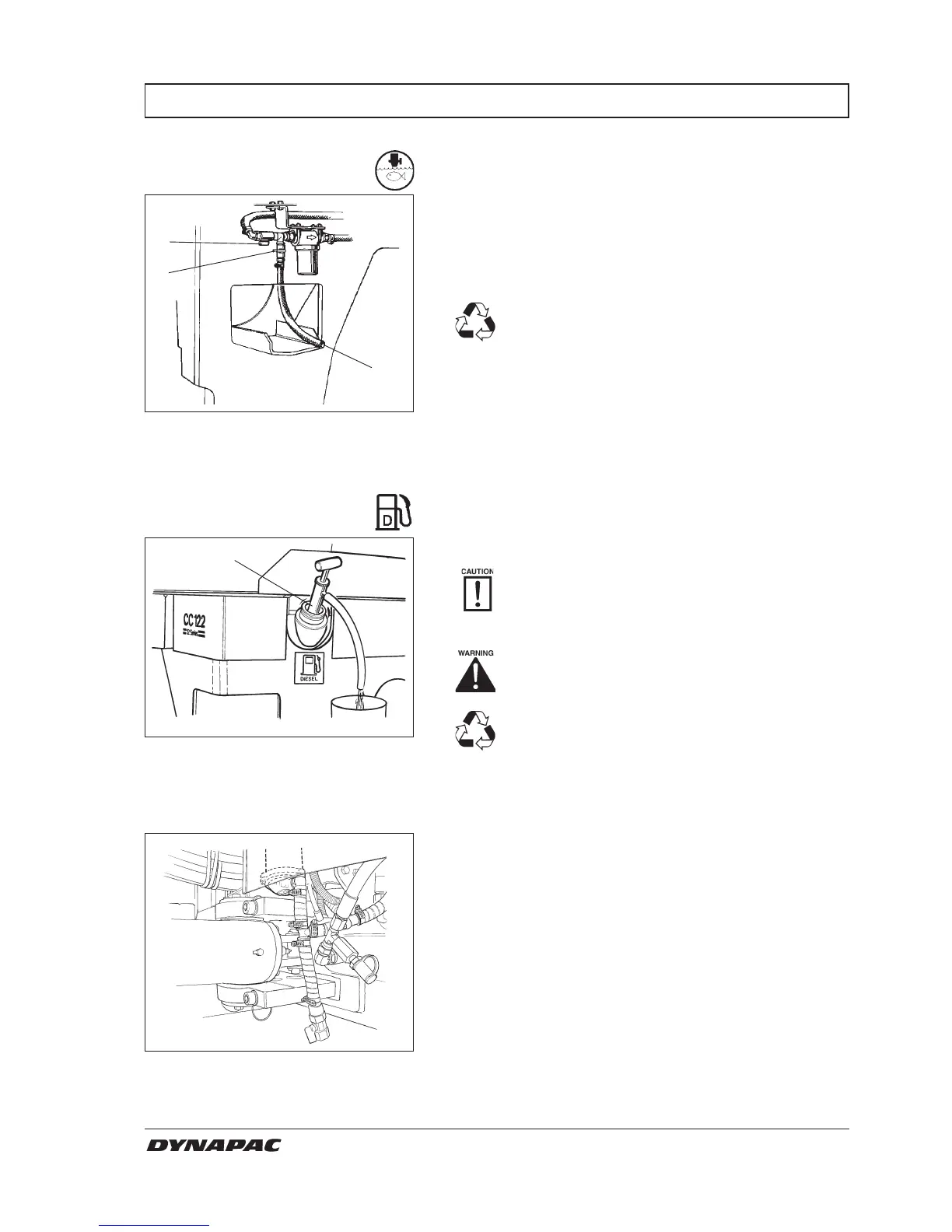

Open the cock (1) and the drain cock (2), which is

located in the left step. The hose (3) facilitates draining

the emulsion fluid into a suitable receptacle.

For cleaning the tank, see Water tank – Cleaning.

The emulsion tank is made of recyclable

plastic (polyethylene).

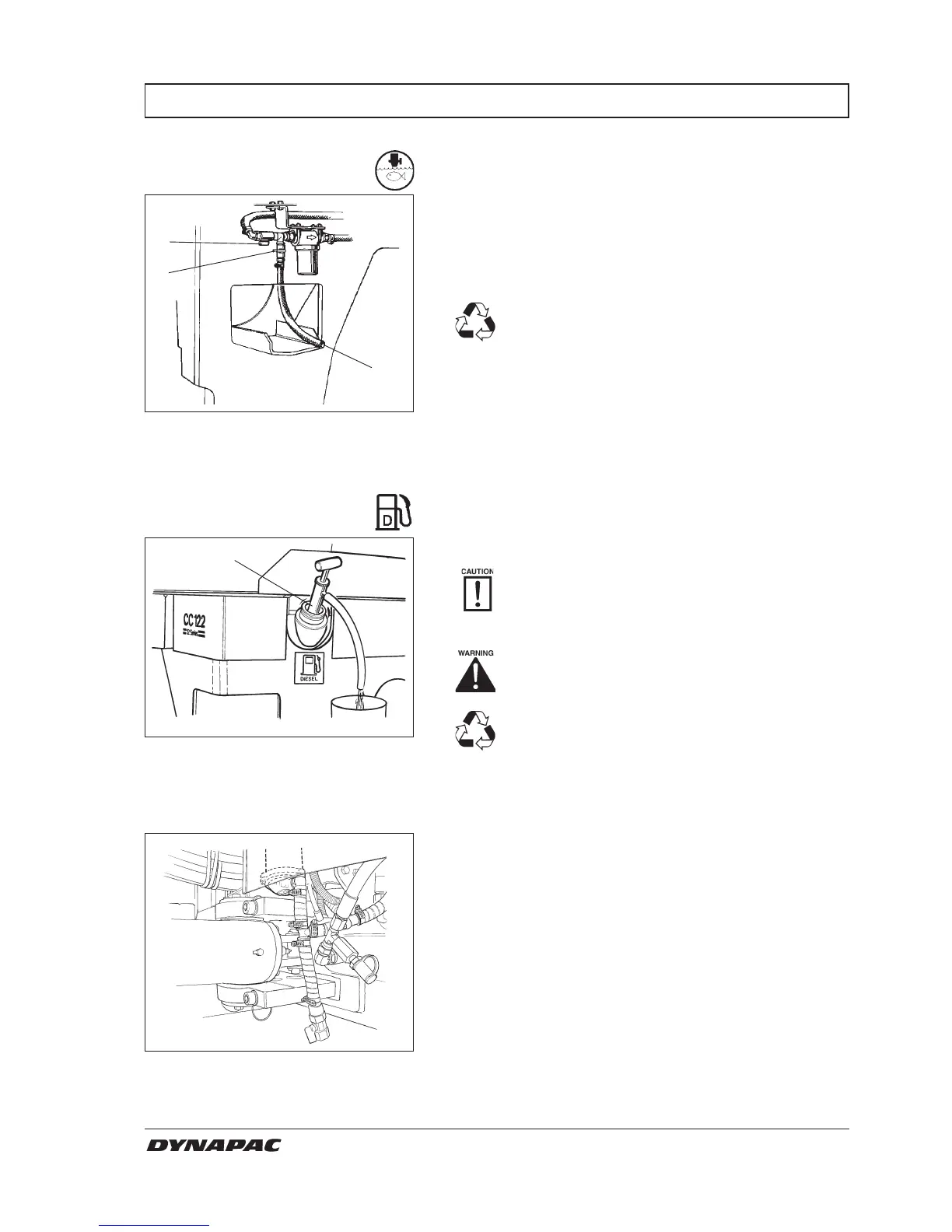

Fig. 50 Fuel tank

1. Oil emptying pump

Fig. 49 Pump system

1. Stopcock

2. Drain cock

3. Drain hose

3

1

2

1

Fuel tank – Cleaning

Emulsion tank

– Draining

EVERY 2000 HOURS OF OPERATION (Yearly)

Steering joint – Check

Inspect the steering joint to detect any damage or

cracks.

Check and correct any loose bolts.

Check also for any stiffness and play.

Fig. 51 Steering joint

Loading...

Loading...