18 CC102/C/122/C/132/142/C M102EN4

Place the roller on a level base. The engine

must be switched off and the reserve/par-

king brake knob pushed in for all checking

and adjustments on the roller unless other-

wise specified.

Battery

Checking the electrolyte level

Never use an open flame when checking

the electrolyte level. Explosive gas is gene-

rated when the alternator is charging.

Fully open the engine hood.

Wipe the top of the battery dry.

Wear safety goggles. The battery contains

acid. Rinse with water if electrolyte comes

into contact with the body.

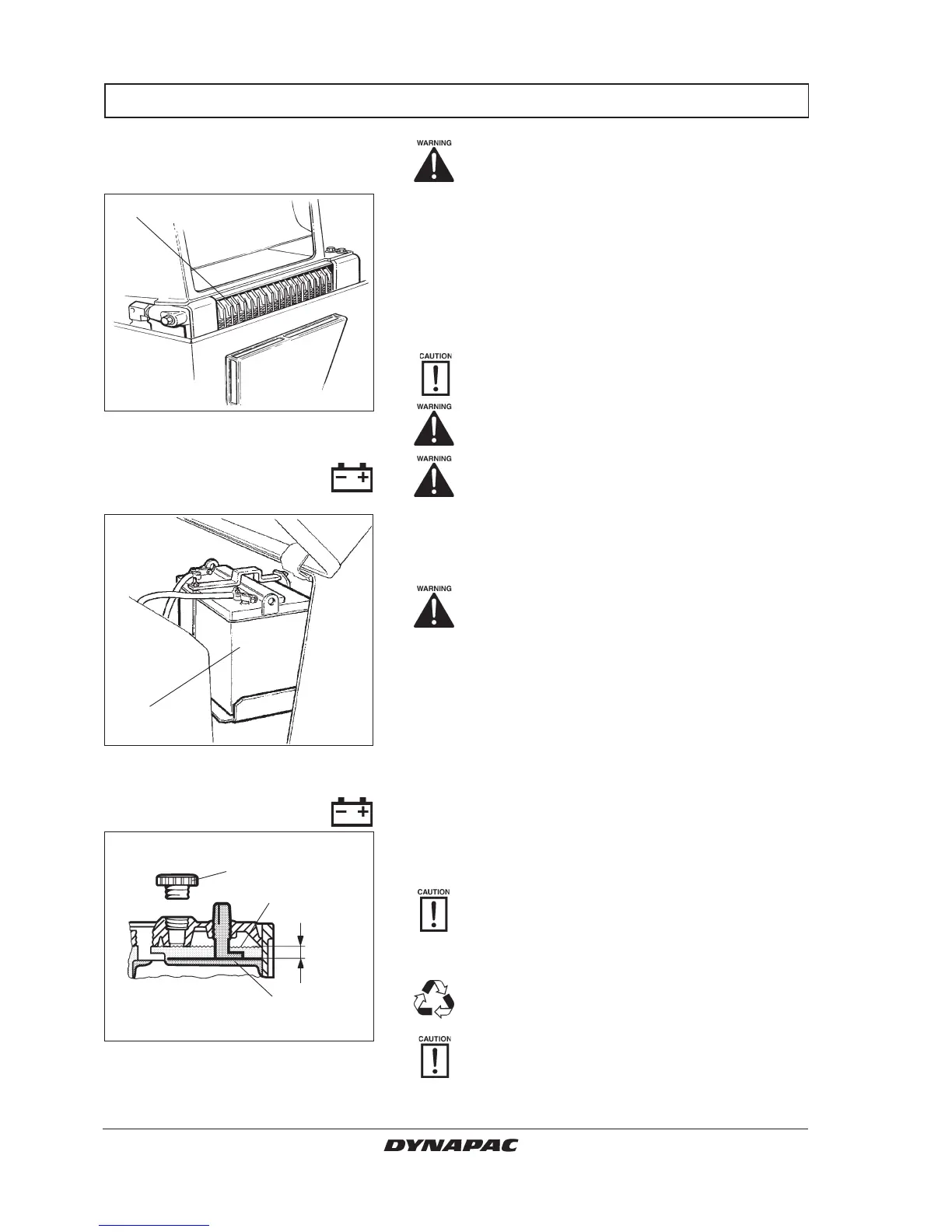

Take off the cell caps and ensure that electrolyte is

about 10 mm (3/8") above the plates. Check the level of

all cells. Top off with distilled water to the right level if

the level is low. Let the engine run for a while before

topping off with distilled water if the ambient tempera-

ture is below freezing. Otherwise electrolyte might

freeze.

Make sure that ventilation holes in the cell cover are not

clogged. Then put the cover back on.

The cable shoes should be clean and well tightened.

Clean corroded cable shoes and grease them with

acid-free Vaseline.

When disconnecting the battery, always

disconnect the negative cable first.

When connecting the battery, always connect

the positive cable first.

Dispose of used batteries properly. Batteries

contain lead, which is harmful to the

environment.

Before doing any electric welding on the

machine, disconnect the battery ground cable

and then all electrical connections to the

alternator.

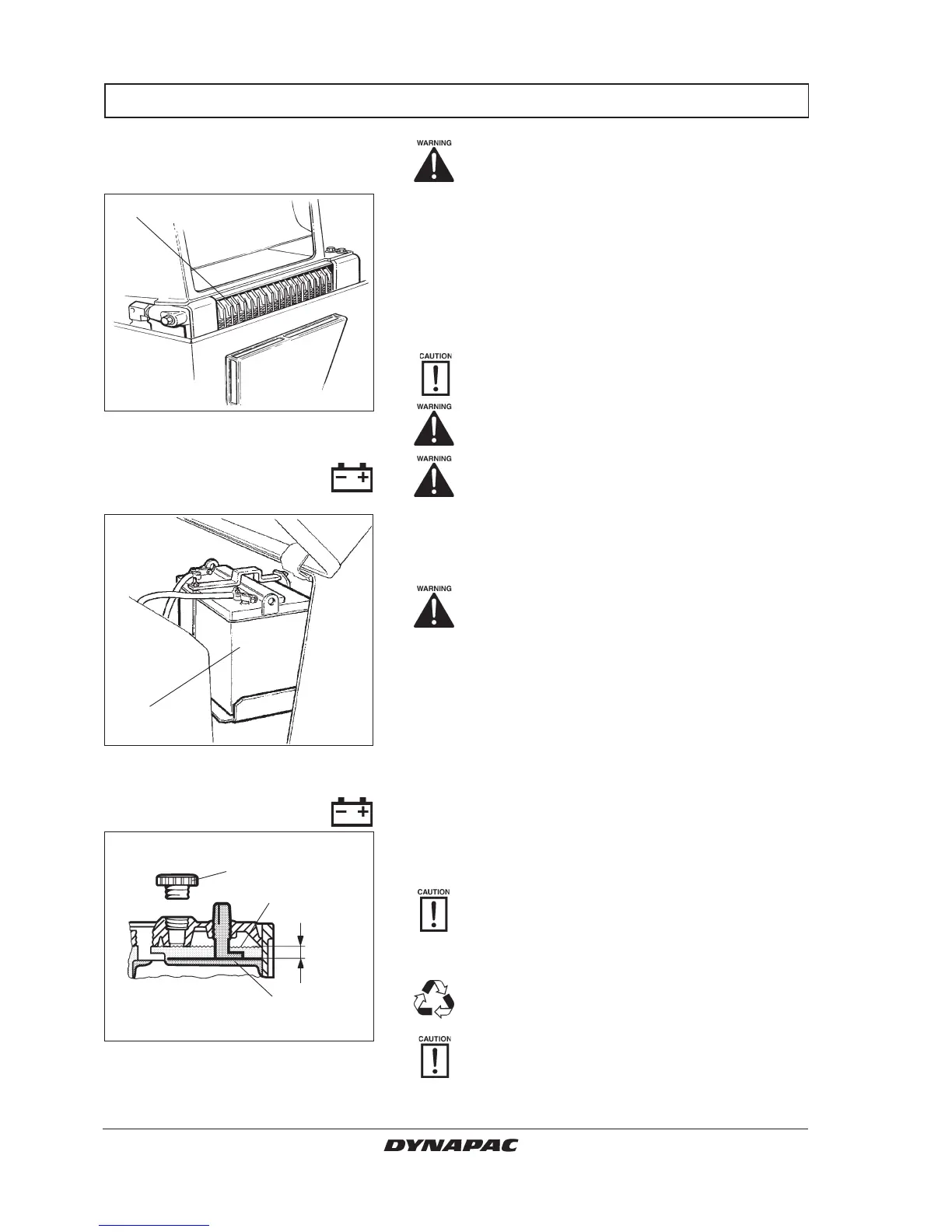

Make sure that the flow of air through the cooler is

unobstructed.

Clean a dirty cooler with compressed air or high-

pressure water cleaning.

Blow or wash the cooler in the opposite direction to that

of the cooling air.

Take care when using a high-pressure water

jet; do not hold the nozzle too near the cooler.

Wear protective goggles when working

with compressed air.

Fig. 22 Engine compartment

1. Hydraulic fluid cooler

1

Hydraulic fluid cooler

Checking – Cleaning

Battery cell

1

Fig. 23 Battery shelf

1. Battery

Fig. 24 Electrolyte level in battery

1.Cell cap

2.Electrolyte level

3.Plate

EVERY 250 HOURS OF OPERATION (Monthly)

1

2

3

10 mm

Loading...

Loading...