20 CC102/C/122/C/132/142/C M102EN4

Place the roller on a level base. The engine

must be switched off and the reserve/par-

king brake knob pushed in for all checking

and adjustments on the roller unless other-

wise specified.

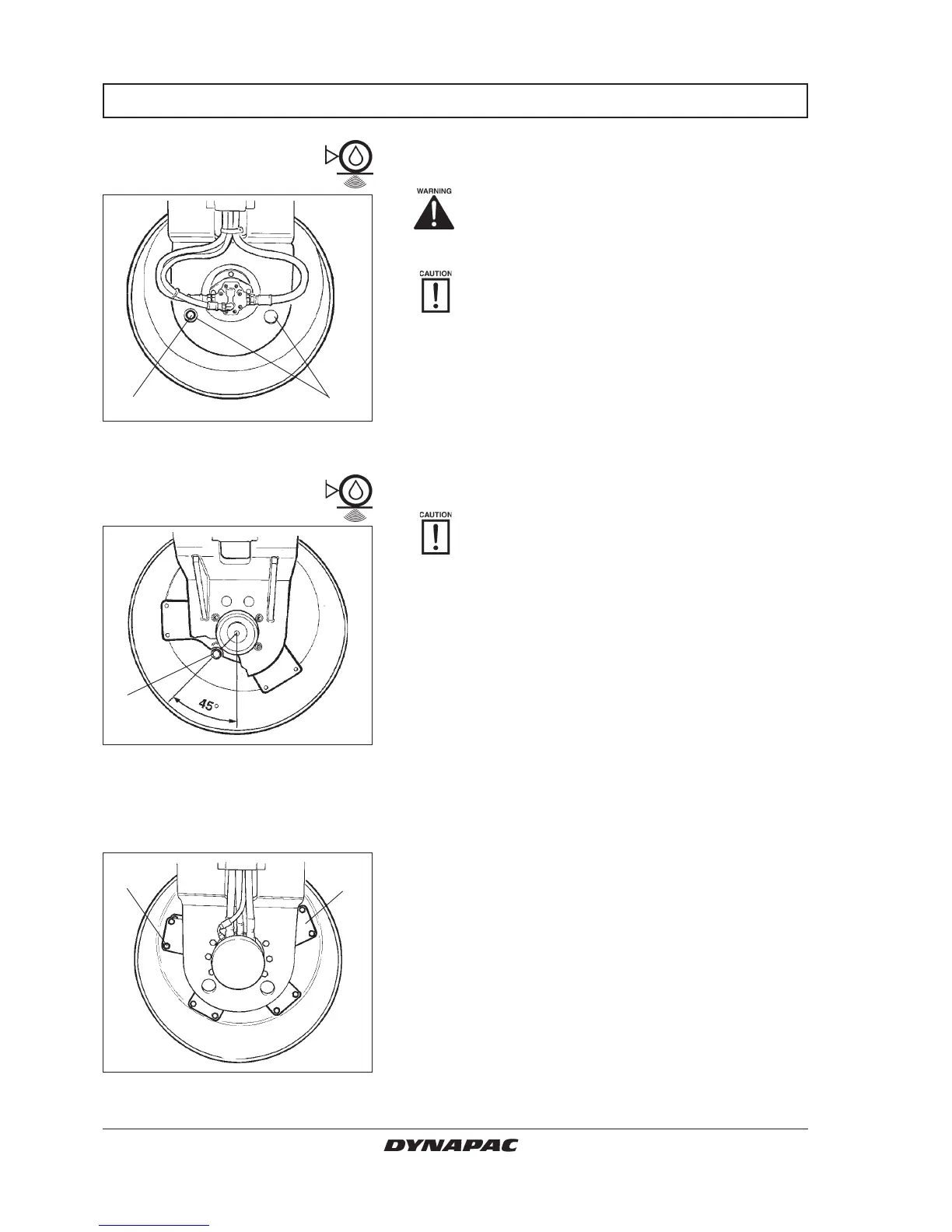

Drum – Oil level – Check

– Filling

This inspection applies to the CC102/122.

Drive the roller slowly until the oil plug (1) is aligned

with one of the check holes (2).

Remove the plug and check that the oil level reaches

the lower edge of the plug hole. Top off with fresh,

clean oil if necessary. Use oil according to the lubricant

specification.

Clean the magnetic oil plug (1) from any metal particles

before refitting it.

12

Fig. 26 Drum, vibration side

1. Oil plug

2. Check hole

Drum

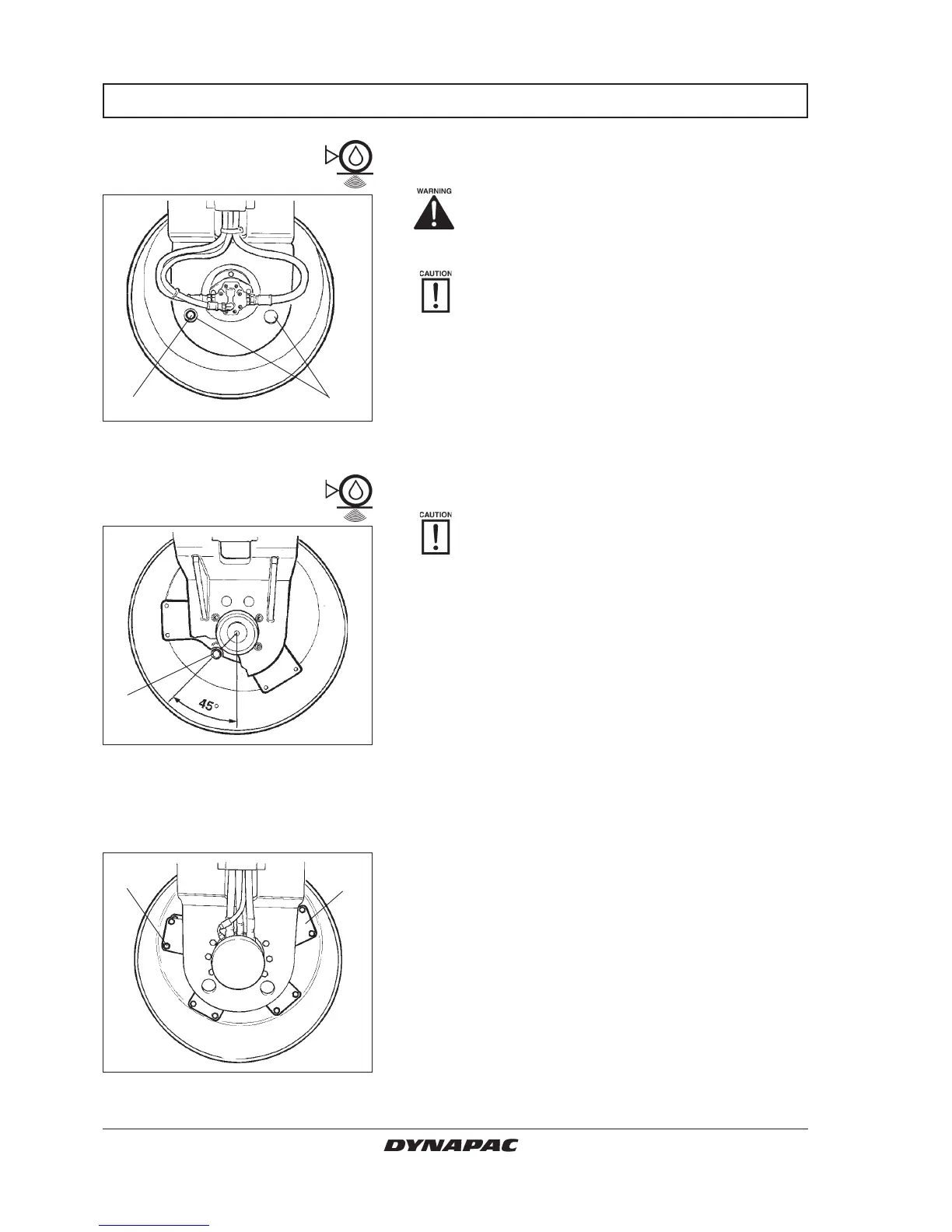

– Checking the oil level

This inspection applies to the CC132/142.

Drive the roller slowly until the oil plug (1) is aligned

with the semicircular recess in the drum suspension.

Remove the plug and check that oil level reaches the

lower edge of the plug hole. Top off with fresh, clean oil

if necessary. Use oil according to the lubricant

specification.

Clean the magnetic oil plug (1) from any metal particles

before refitting it.

1

Fig. 27 Drum, drive side

1. Oil plug

EVERY 500 HOURS OF OPERATION (Every three months)

Fig. 28 Drum suspension

1. Rubber element

2. Fastening screws

1

2

Rubber elements and fastening

screws – Check

Check all rubber elements (1). Replace all of the

elements if more than 25% of them on one side of the

drum are cracked deeper than 10-15 mm (3/8–5/16").

Use the blade of a knife or pointed object to assist

when checking.

Make sure that the fastening screws (2) are tightened.

Loading...

Loading...