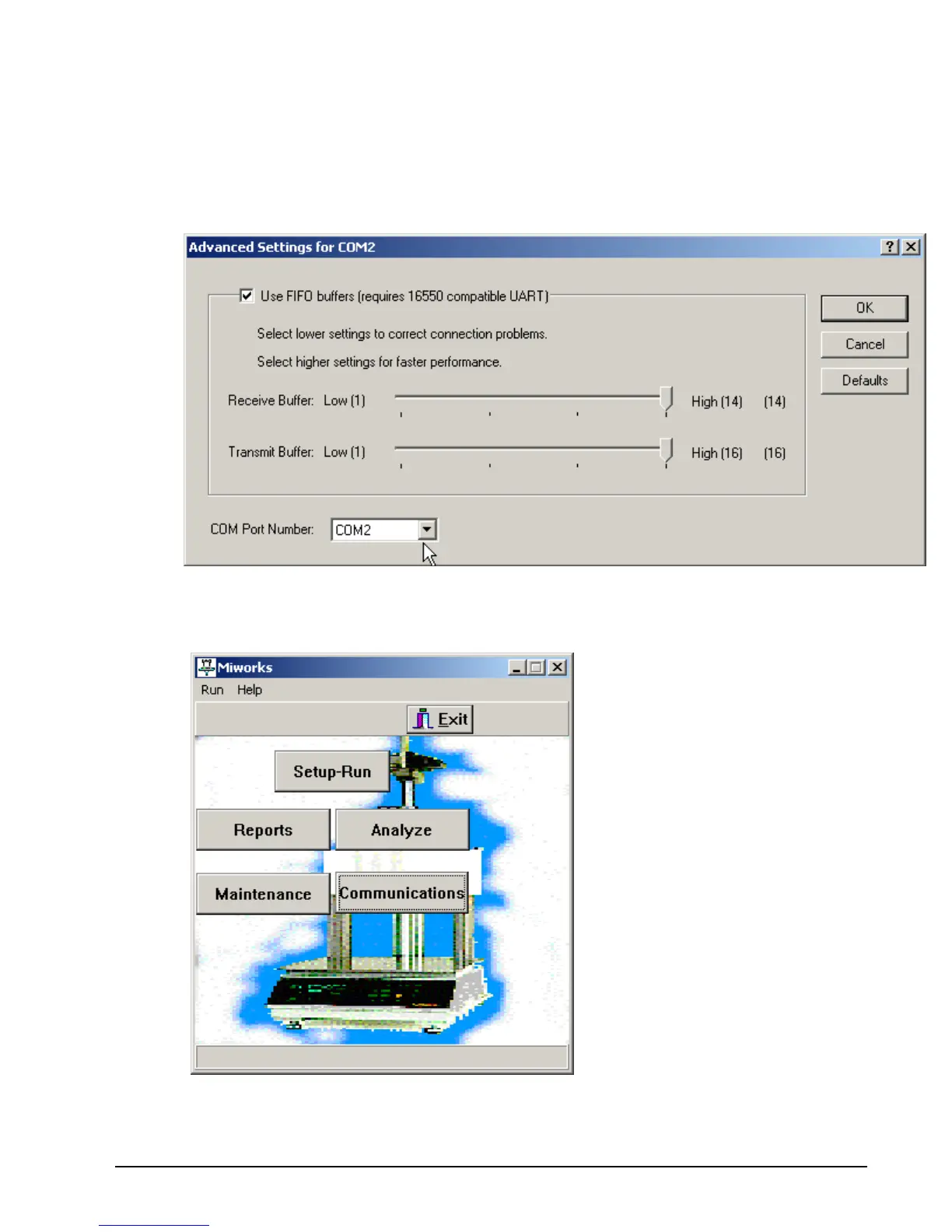

7) Select “Advanced”. In “Advanced Settings”, select “COM2” (or COM1), then

“OK” to “Advanced Settings, then “OK” to “Communications Port Properties”.

Then, close Device Manager.

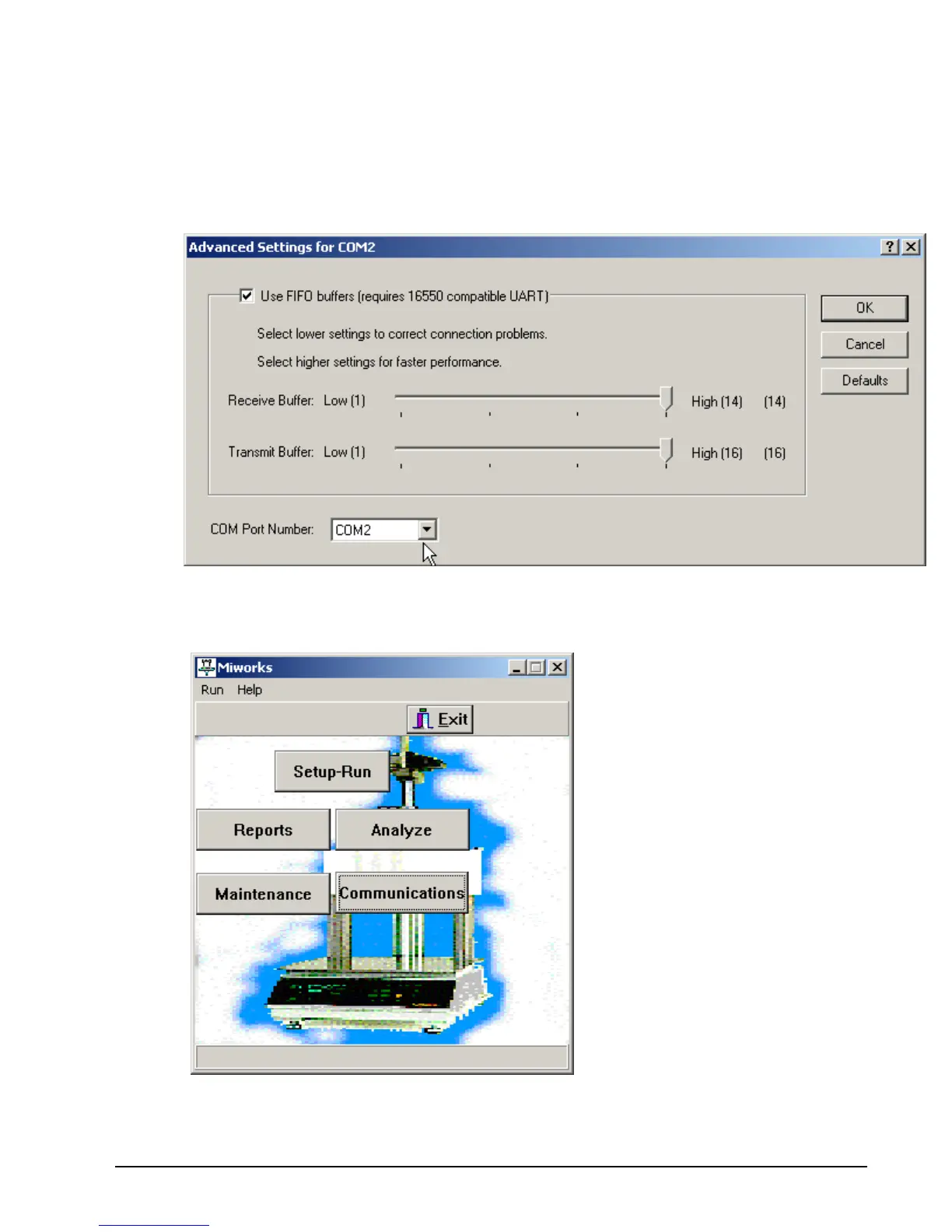

8) Start MI Works and the following window should appear:

Series 4000 Melt Indexer Operation Manual USB Setup

79

Loading...

Loading...