EC5000

- 30 - - 31 -

Operation and inspection

3

EC5000

Installation and Wire Layout

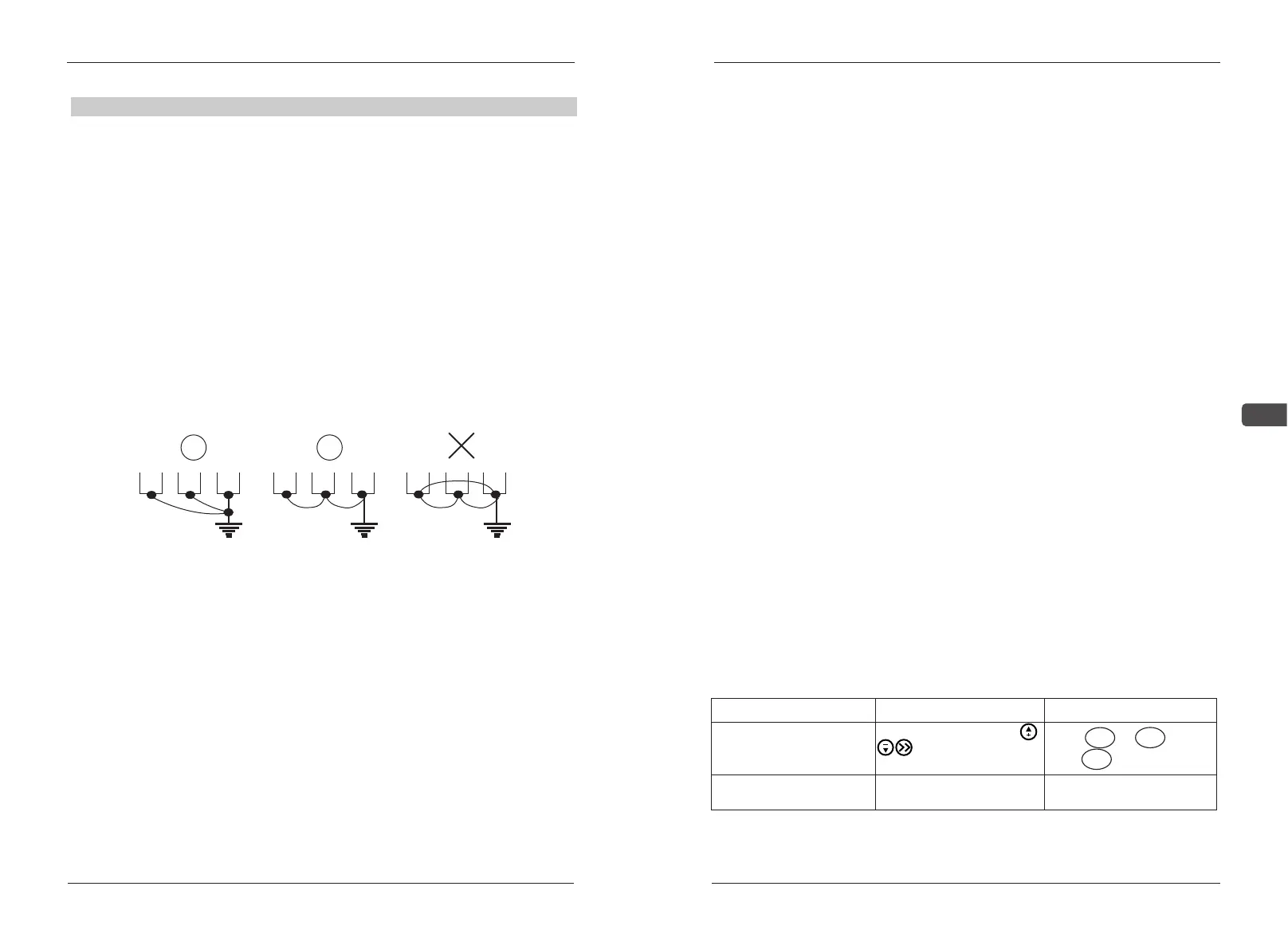

Best Fair Wrong

■ For safety and noise reduction, the grounding terminals of AC drive

should be well grounded.

■The grounding wire of AC drive can’t be grounded together with the

machines with heavy current load e.g. the electric welding machine and

high power motor, they should be grounded separately instead.

■ In order to prevent electric shock and fire, the external metal

grounding wires of electric equipment should be wide and short, and

connected to the special grounding terminals of the AC drive system.

■ If there is more than one AC motor speed controller connecting

with the ground, Please make sure that is does not form grounding loop,

shown as the following figures:

Grounding terminals of AC drive (EG)

3.1 Check and Test Before Operation

The following matters should be paid attention before the operation:

■Check if wire connection is correct. Confirm AC drive output permInal

U, V, W is not connected to POWER and the ground terminal E(G) is grounded

well.

■ Confirm there is no short circuit within every terminal and electricitied

naked part.

■Confirm all terminals connection and joints are tight and not loose

■Ensure that the motor isn't connected with loaded machine.

■Before turning the power on, ensure that all the switches are in the

disconnected state to guarantee that the AC drive won't start or operate

abnormally when the power is on.

■ The power supply can only be turned on after the upper cover is

installed.

■It is forbidden to operate the switch with wet hand.

■Display of the keypad panel (no indication of faults)

■The cooling fan installed in the AC drive should work normally.

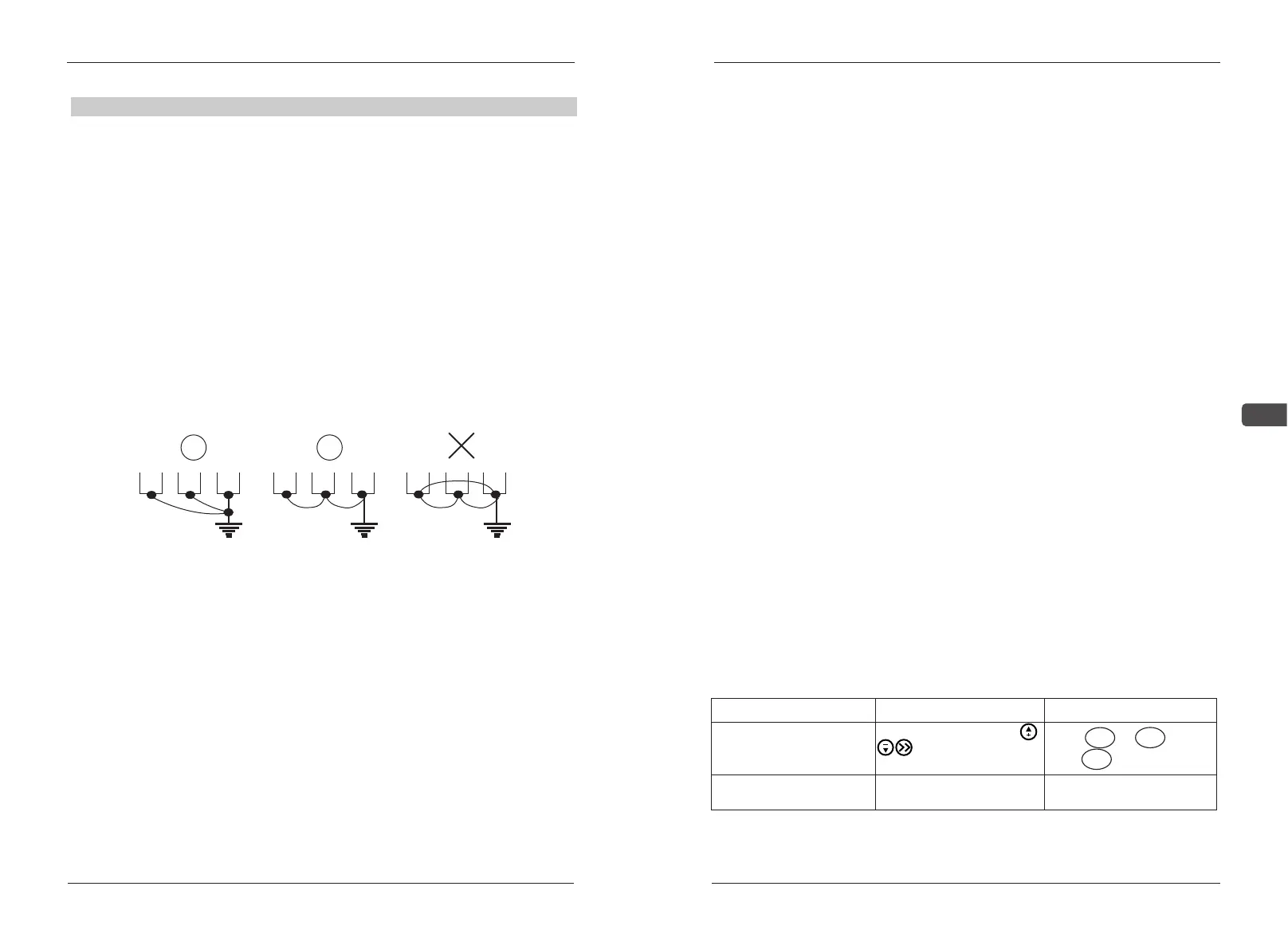

3.2 Running Way

There are many running ways showed in “Chapter 4 CONTROL PANEL

AND OPERATION” and Chapter5 “FUNCTION DATA ILLUSTRATIO

N”.Choose the best operation way according to actual need and running

regulations. The common running ways are listed on figure 7-1

running way

key panel operation

Remote Control

Keyboard keys select

or panel adjustment

potentiometer

frequency setting

potentiometer or

simulated voltage current

running order

Press FWD or REV to start

and STOP to stop

Input joint terminal S1-

SC、terminal S2-SC

Loading...

Loading...