EC5000

- 32 - - 33 -

Operation Keypad Panel

4

EC5000

Operation and inspection

Check whether the acceleration / deceleration are steady.

If there is no abnormality, perform the test run with frequency increased. If

no abnormality happens in the test run above, the formal operation can be

started.

If there is any abnormal phenomena occured, stop AC drive immediately.

Consult “ fault diagnosis” to find the problem. When AC drive stops,

terminal L1/R1, L2/S, L3/T is still with power if main circuit is not

switched off. Any touch onto terminal U, V, W will be shocked. Besides,

wave filter capacitor is still full of charging voltage and need certain period

of time to discharge, if main circuit power is off. Touch inner AC drive circuit

only after power and the DC circuit voltage tested by DC circuit voltage

meter is below safety voltage.

Notice!

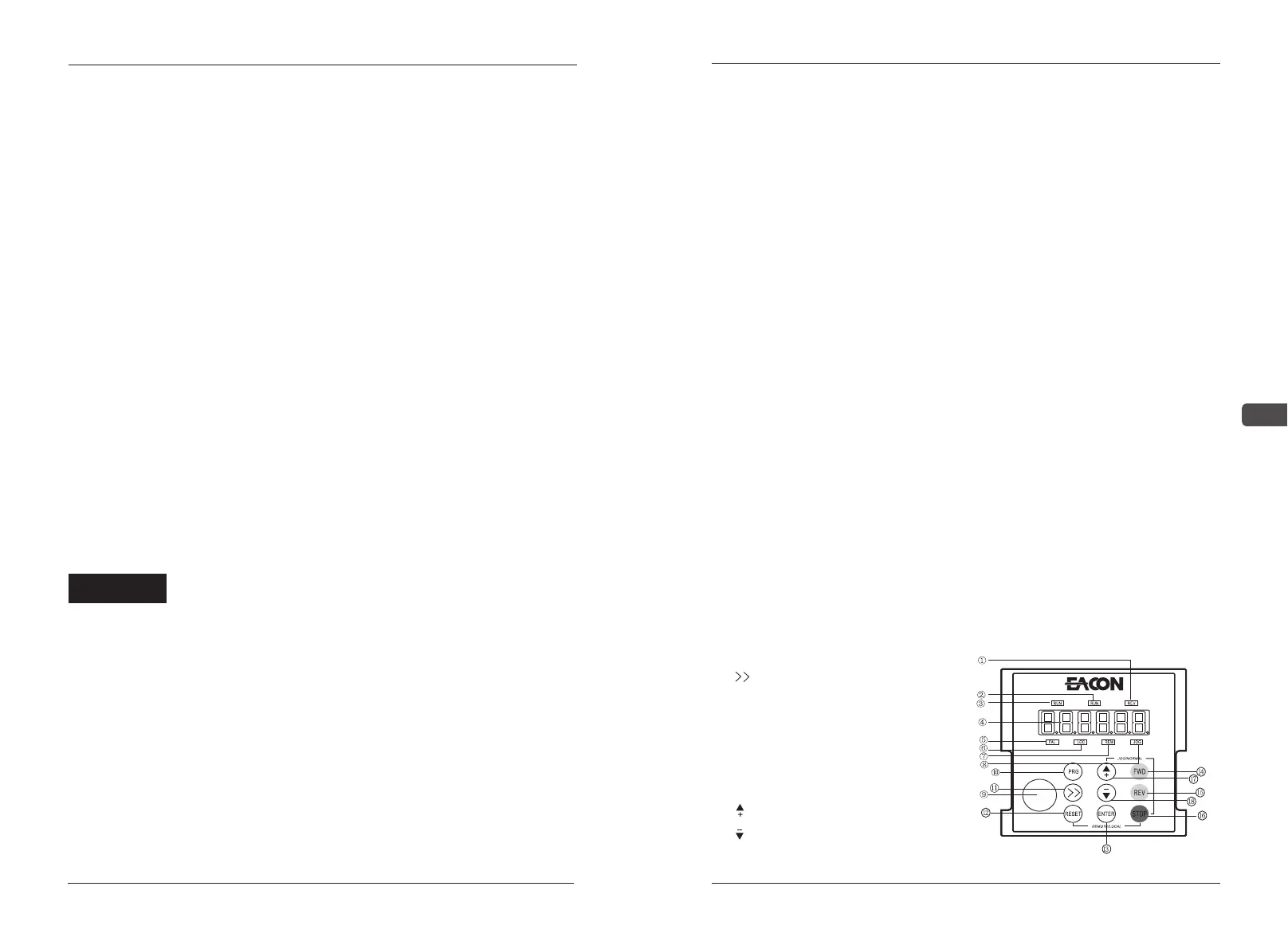

4.1 LED Keyboard Panel Appearance and

Operation Process

8 segment digital tube LED operation panel by six and seven leds, it can

display the running condition of AC drives, running direction, alarm, forecasting

warning information, panel/remote instruction, monitoring data, I/O status, the

parameters of the function of data set, etc.

The panel is detachable and isolated from the input potentiometer. The

panel is allowed to be removed during operation, but it is not recommended to

do so when running in relation to the panel, such as panel control

running/stopping and setting the frequency.

4.1.1Appearance of the Keypad Panel of Nixie

Tube

①REV This LED indicator light will be on when the motor is in positive rotation

②FWD This LED indicator light will be on when the motor is in reverse rotation

③RUN This LED indicator light will be on when the motor is running

④6-bit LED nixietubes display

⑤FAL This LED indicator light will be on when the frequency converter has faults

⑥LOC This LED indicator light will be on when controlled by the Panel

⑦REM This LED indicator light will be on when controlled by the control mode set by A03

⑧JOG This LED indicator light will be on when inching condition

⑨Knob of encoder

⑩PRG Enter set parameters

⑪ Move the position on the display

⑫RESET Abnormal reset; Exit after setting

⑬ENTER Parameters validation

⑭FWD Motor reverse rotation key

⑮REV Motor positive rotation key

⑯STOP Motor stop

⑰ Add value or move up parameters

⑱ Reduce value or move down parameters

3.3 Test Run

If no abnormality is detected after the inspection and preparation before the

operation according to 3-1, the test run can be performed. When the products

leave the factory, they are set to work in the external terminal operation mode,

which can be switched to manipulator operation mode via the key combination

of

1. After the power supply is on, confirm that the LED displays the frequency

0.00Hz.

2. Use the key to set low frequency around 5Hza

3.Press or to start and to low down and stop

4.Check the following before running:

Check whether the rotation of motor is correct.

Check whether the rotation of motor is steady (without abnormal noise or

vibration).

Loading...

Loading...