EC5000

- 118 - - 119 -

Maintenance inspection

8

operation with cover removed begin.

2.No one other than the appointed operators could perform

maintenance and part replacement and other operations.(Metal objects

such as watches and rings should be taken off before operation, and use

tools with insulation in operation.)

3.Rebuilding the AC drive is absolutely forbidden.

4.Avoid electric shock and facility accident.

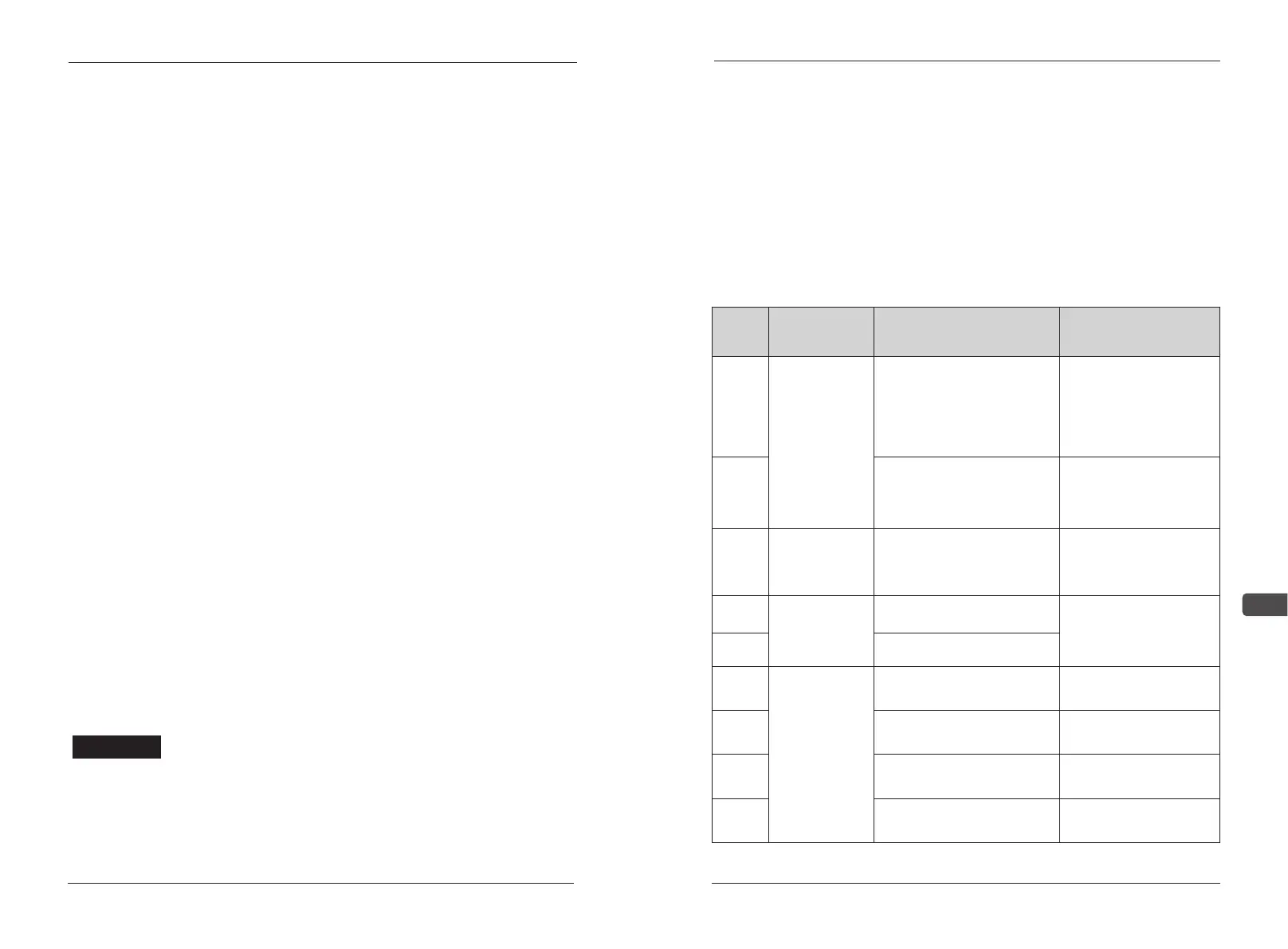

List of Periodic Inspection

Inspection Items Inspection Method

Spot

Check

Period

Cheeck site

Environment

Confirm environment

temperature, humidity,

vibration and whether

there’s dust, gas, oil mist

and water drops and so on.

With eye survey and

apparatus measuring

Are there any foreign bodies

like tools or dangerous goods

nearby?

With eye survey

Daily

Daily

Voltage

Are voltages of main circuit

and control circuit both

normal?

Measure with a

multimeter

Daily

Daily

Daily

Is the display clear?

With eye survey

Is any character missing?

Keyboard

Display Panel

Is there any abnormal sound

or vibration?

Are the bolts (fasteners)

loose?

Is there any distortion and

damage?

Is there color change due to

overheat?

With eye survey and

hearing

Fasten

With eye survey

With eye survey

Mechanism

Parts

Half

yearly

Half

yearly

Half

yearly

Half

yearly

Maintenance inspection

EC5000

8.1 Daily Inspections

8.2 Periodic Inspection

AC drive consists of multiple parts including electronic parts such as

ICs, resistors, capacitors and transistors as well as cooling fans and

relays and so on. These parts aren’t permanently durable and cannot be

used forever. Even if used under normal environment, once the life

period has exceeded, faults are easily to occur. Therefore, preventive

periodic check is necessary, in order to find out the parts with poor

quality or those fall short of the standard, and eliminate the causes for AC

drive malfunction. At the same time, the parts that have exceeded their

life period could also be replaced, so as to ensure fine operation.

During power-up and operation, without taking away the cover,

check the operation of AC drive with eye survey from outside and confirm

that there’s nothing abnormal. Usually, check the followings:

■whether the operation performance accord with the regulation

■whether the environment accord with the regulation

■whether keyboard panel display is normal

■whether without abnormal noises, vibrations and abnormal odor

■whether without abnormality such as overheat or change in color

Before doing the periodic inspection, first stop operation, shut off

power supply and take away the cover.

Even when the power supply of the AC drive is shut off, there’s still

charged voltage on the filter capacitors and it takes some time to

discharge. In order to avoid the danger, be sure to wait until the charge

indicator goes out and test with a voltmeter to ensure the voltage is lower

than safe value(≤25Vdc) before the operation of inspection.

1.For AC drives ≤ 22kW, wait 5 minutes after shutting down the

power, and wait 10 minutes for those ≥ 30kW. Not until the DC voltage

between terminals N- and P+ is lower than DC25V could examination

Notice!

Loading...

Loading...