04/10 MN04020001Z-EN

Modbus parameters

137

For Modbus to function at least the following parameters must be

set:

Another requirement is that the arrow

C in the lower status line

of the LCD display is pointing to BUS (adjustable via the LOC/REM

button). The PLC (master) must also be provided with an RS485

serial interface and the necessary Modbus RTU driver software.

Operating mode Modbus RTU

Operating mode Modbus RTU (Remote Terminal Unit) transfers

the data in binary format (faster data rate) and determines the

transfer format for the data request and the data response. Each

message byte that is sent contains two hexadecimal characters

(0 … 9, A … F).

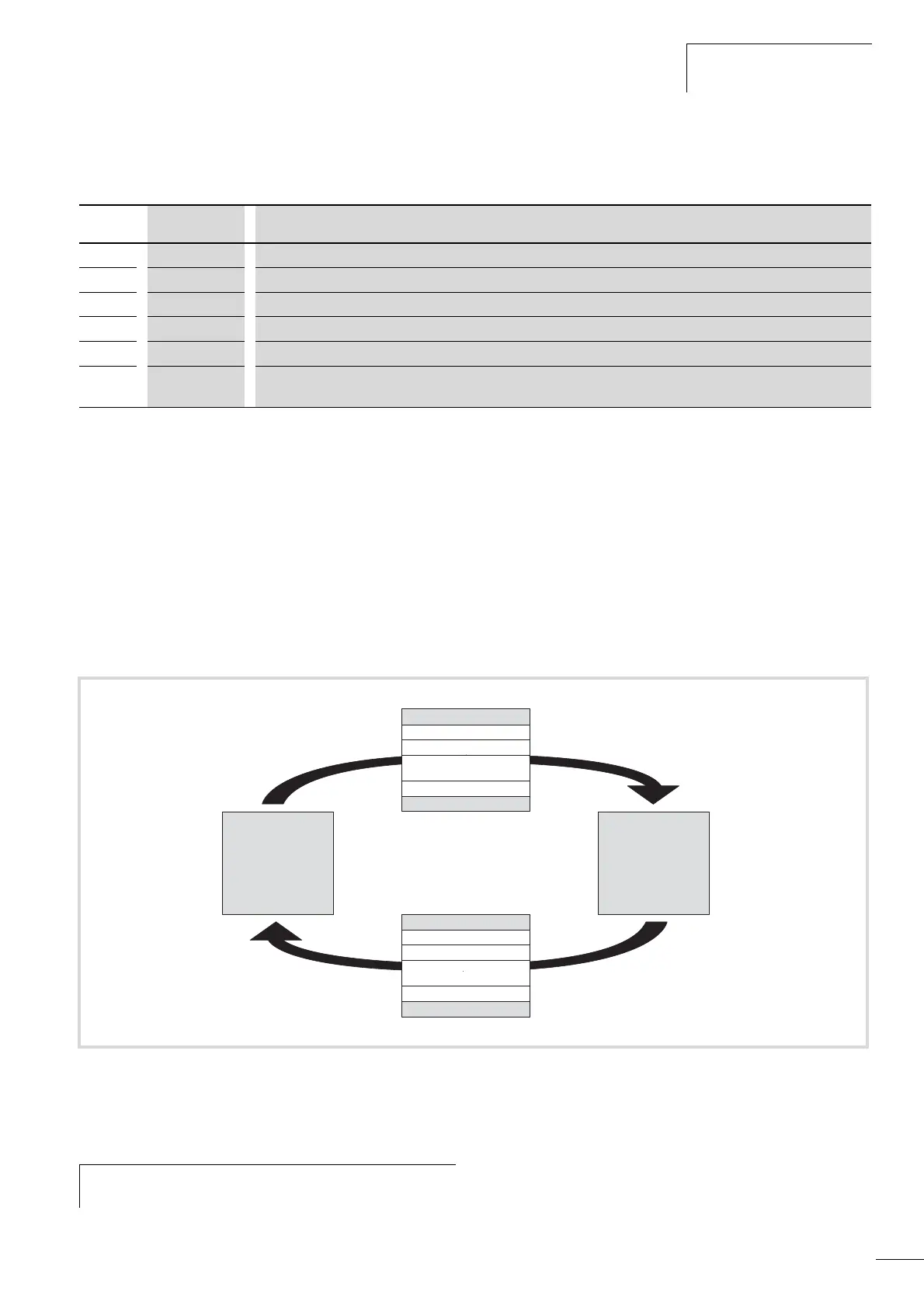

The data transfer between a master (PLC) and the frequency

inverter (M-Max

TM

) is carried out according to the following

sequence:

• Master request: the master sends a Modbus frame to the

frequency inverter.

• Slave response: the frequency inverter sends a Modbus frame as

a response to the master.

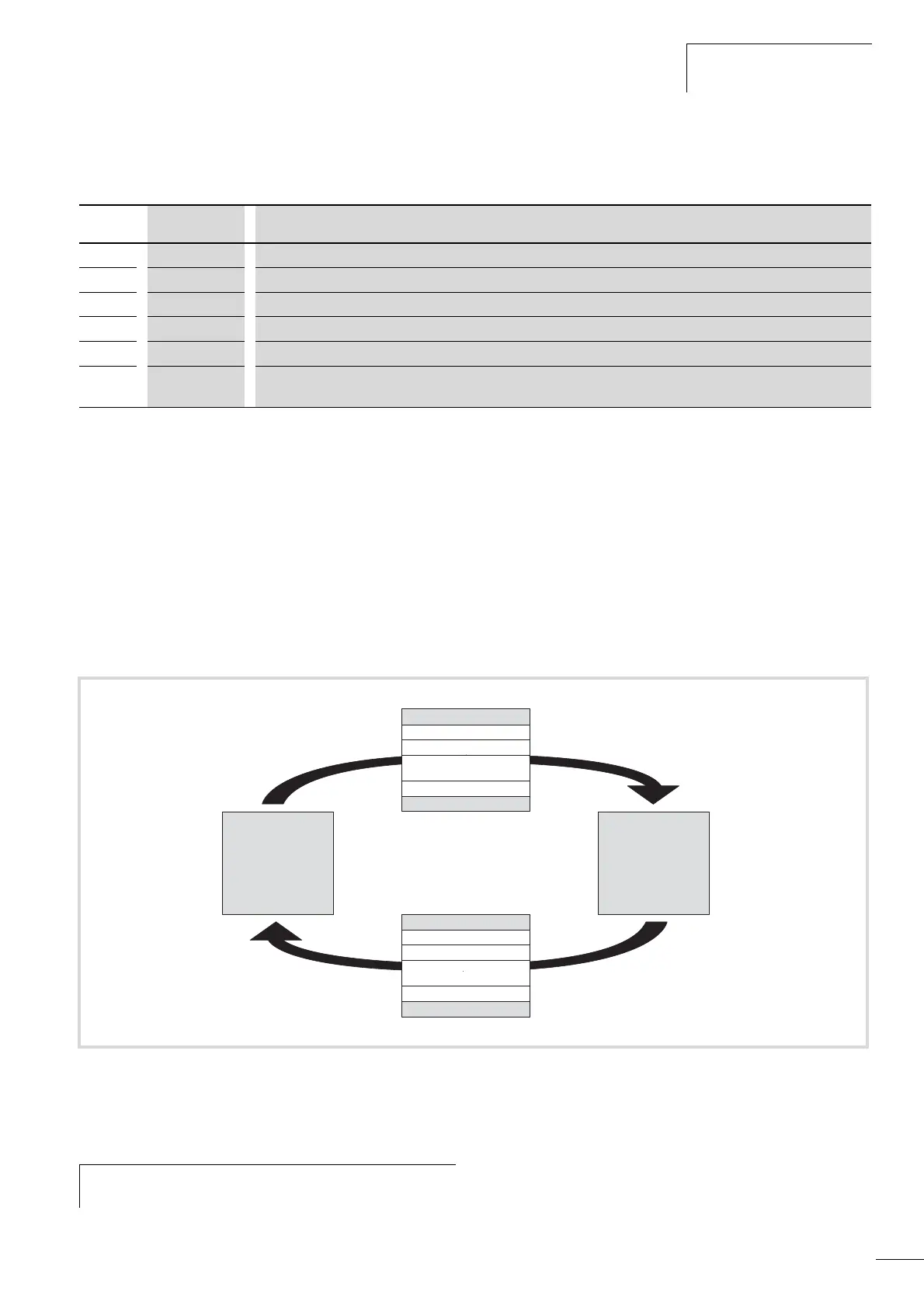

PNU Value Notes

S2.2 1 To activate Modbus.

S2.3 1 - 255 Set differently at each slave (MMX); 0 is used by the master for broadcasts.

S2.4 0-8 Same setting at the master and slave.

S2.6 0/1 Same setting at the master and slave.

6.1 3 Fieldbus selected as a control level.

6.2

2 Set setpoint value via the fieldbus; other setpoint sources also possible, fixed frequencies overlay all setpoint values,

also a fieldbus setpoint value.

Figure 107: Data exchange between master and slave

a Master request

b Slave response, not with broadcast

Start

MMX... (Slave)Master

Address (1 Byte)

Function code (1 Byte)

Data (N x 1 Byte)

CRC (2 Bytes)

End

Start

Address (1 Byte)

Function code (1 Byte)

Data (N x 1 Byte)

CRC (2 Bytes)

End

h

The frequency inverter (slave) only sends a response if it

has received a request from the master beforehand.

Loading...

Loading...