23

Instruction Booklet IB02402001E

December 2010

Instructions for the Eaton Type

MPCV Network Protection Relay

EATON CORPORATION www.eaton.com

IB02402001E For more information visit: www.EatonElectrical.com

Instruction Bulletin

Effective: September 2004 Page 23

Instruction for the

Cutler-Hammer Type MPCV

Network Protection Relay

Installation Rules

In order to deliver a comprehensive and powerful

energy management solution for use in electrical distribu-

tion environments while ensuring affordability, flexibility,

simplicity and noise immunity the following rules will allow

the user to achieve the above advantages. These rules

are expected to be followed as a starting point before

troubleshooting is performed on a system.

1. Cable Selection

The approved cable types are:

■ Any of the cable in the Belden 9463 family.

■ IMPACABLE — a 600 volt rated custom designed for

IMPACC Style No. 2A95705G01.

2. Cable Intermixing

Any of the above approved cables may be intermixed

without compromising communication performance.

3. System Topology, Size and Capacity

Topology

■ Bus or single star.

■ Maximum number of long line from star: 5.

■ No line termination for tap.

■ Required EOLTR (100 ohms) at the end of long line.

■ Maximum cable length between ends of longest lines:

10,000 feet (3,048 m)

Attenuation:

■ Total system attenuation capacity: 25 dB.

■ Attenuation per device: 0.01 dB.

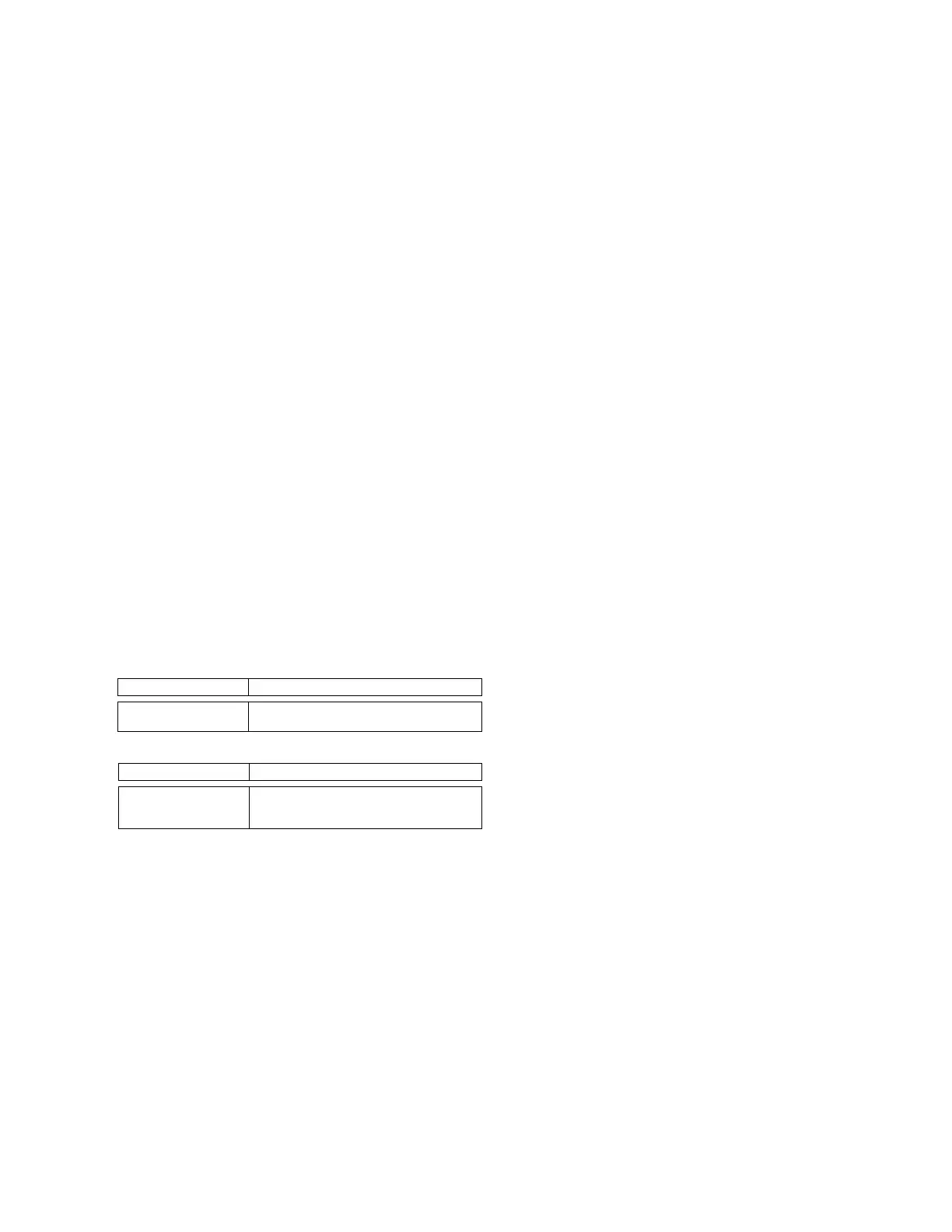

■ Attenuation of approved cables:

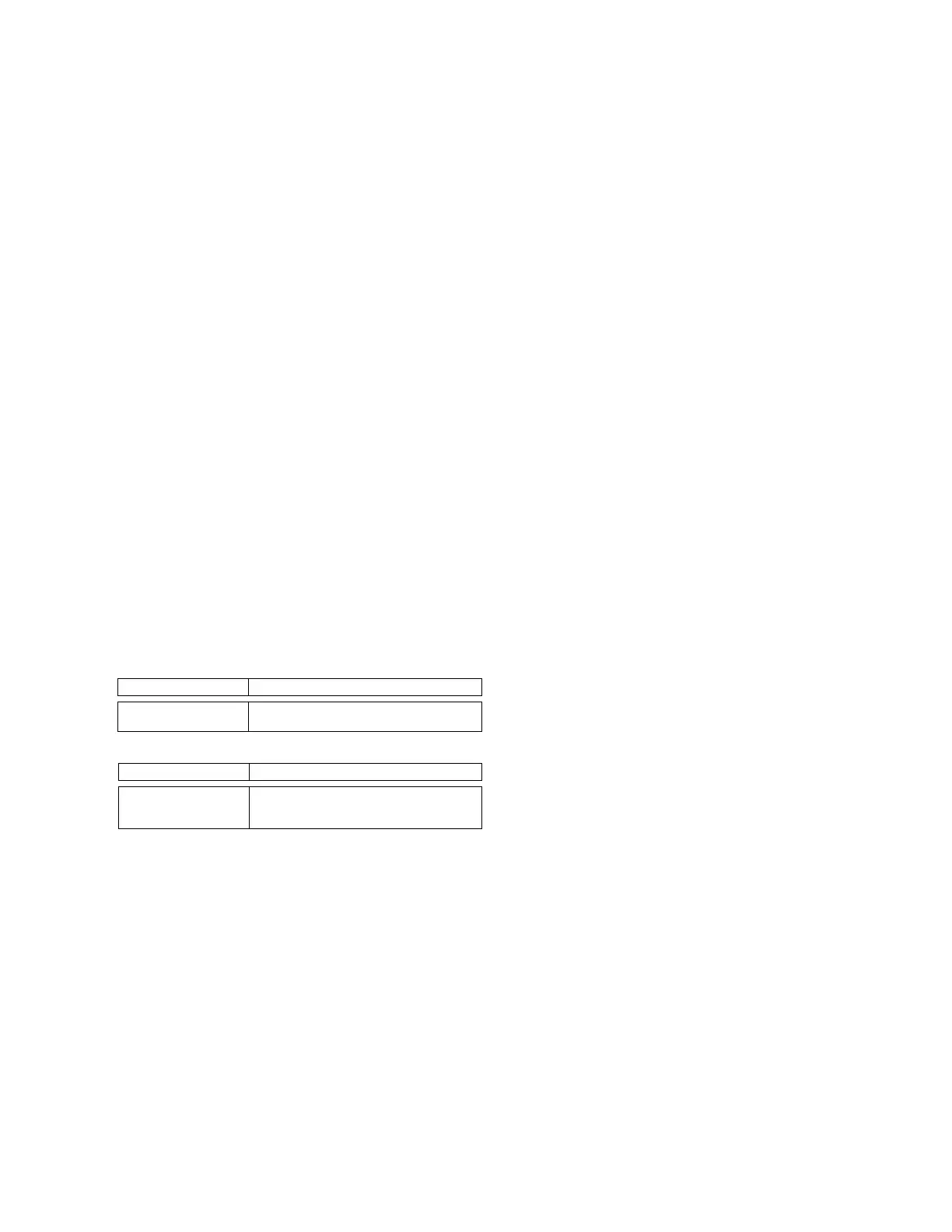

■ Attenuation at Star:

Definition

STAR — single point with a number of long lines

emanating from it.

LONG LINE — greater than 200-foot (61 m) wire run.

4. Cable Splicing

The prime goal is to create a secure electrical connection

while minimizing exposure to electrical transients.

■ Ferrules are used to dress cable ends in order to avoid

problems associated with frayed and loose wires.

■ Use the device built-in two pole terminal blocks when

splicing.

■ All devices, EOLTR, Simple Taps and Complex Taps

should be placed in parallel across the cable.

5. Cable Shielding

■ Cable shielding and outer jacket should not be stripped

longer than 1-1/2 inches (38.1 mm).

■ Use the three pole terminal blocks at tap points to ensure

a continuous metallic shield ground path.

■ Mechanically crimp sleeves on to the two-shield path

drain wires

■ The cable shield ground path for a Main Network and

Subnetwork must not be joined together. Each should

have a separate connection to earth ground reference.

6. Cable Grounding

■ The shield ground path of a Main Network (and each

subnetwork) should be broken up into two separate

isolated segments in such a way that a single, solid earth

ground is available within 3,000 feet (914.4 m) of any point

along the Main Network (or subnetwork).

■ Do not tie together drain wires of neighboring segments

to achieve isolation.

■ Insulate unused drain wire to prevent accidental

grounding.

■ Connect the shield ground path’s drain wire to a #14

AWG or larger multi-stranded wire that has an impedance

path of 1 ohm or less to a known earth ground. Note that a

new ground path will be required when the shield ground

travel through many connections and considerable

distances before reaching earth ground.

7. Cable Termination

The Main Runs of the Main network and each Subnetwork

require a pair of EOLTR, rated 100 ohms, _ watt carbon or

metal film resistors. Do not use wirewound resistors.

■ The resistors should be placed in parallel across the

splicing junction servicing the Complex Tap rather than

at the far end within the Complex Tap.

■ Tap off from the Main Runs do not require EOLTR.

8. Device Address

To avoid the possibility of devices in a Main Network having

the same address as those in Subnetworks, set the Main

Network device addresses to start at 100 or higher excluding

901 to 908.

Cable Type Attenuation per 1,000 ft. (304.8 m)

IMPACABLE

Belden 9463

1.6 dB

2.0 dB

No. of Long Lines Attenuation

3

4

5

3.5 dB

6.0 dB

8.0 dB

Loading...

Loading...