8

Instruction Booklet IB02402001E

December 2010

Instructions for the Eaton Type

MPCV Network Protection Relay

EATON CORPORATION www.eaton.com

For more information visit: www.EatonElectrical.com IB02402001E

Instruction Bulletin

Page 8 Effective: September 2004

Instruction for the

Cutler-Hammer Type MPCV

Network Protection Relay

Instructions for the Type MPCV-D Relay used on

Type CMD, 216 Volt, Network Protectors

I. Installation

a. Remove the CN-33 master relay and the CNJ phasing

relay, as well as the BN relay. Install a BN dummy or

jack plate if a BN relay was removed. If there is no BN

relay, but the position is taken by a BN dummy plate

or BN jack plate. DO NOT REMOVE THE BN DUMMY

OR JACK PLATE.

b. Install Style No. 508B559G01 phasing jumper plate in

the location of the CNJ phasing relay.

c. Install the Type “MPCV”, Style No. 6417C82G01, in

location of the CN-33 master relay.

If the network protector is wired for an electromechanical

watt-var relay, the wiring must be changed over to the watt

trip characteristic. Refer to l.B. 35-552, Pages 36 – 37. The

MPCV can be set for a watt or watt-var trip characteristic.

Although its input is connected as a watt characteristic, the

change to watt-var is accomplished by changing the “WV”

set point from OFF to ON.

II. Calibration

a. Connect a network protector portable test kit to the

network protector. Specific instructions for performing

this task are contained in I.B 35-556.

b. Power-up the test kit in the relay test mode. Set the

test kit to zero phasing volts, either in phase or at 60

degrees. Once the test set is powered with zero phas-

ing volts, (the Variac set to zero), the MPCV Relay will

advance to float. This indicates that the power-up

mode of the relay is correct. Connect the setting

pendant to the relay, by plugging the setting pendant

into the exposed 9 pin “D” connector.

Note: Note the connector and plug are polarized to prevent improper

connection.

c. De-press the EDIT key to begin the “Edit” mode.

Note: At this point, the amber float light will begin to flash and the

first set point, with its loaded value, will appear on the display of the

pendant. While in this mode, the relay will not change state and is

effectively inoperable for normal relay functions.

d. To change a set point, de-press the large or small,

up or down arrow keys for large or small increment

adjustments until the desired value appears on the dis-

play.

e. Once the desired value is obtained, de-press the NEXT

key. The program will automatically step to the next

set point to be set.

f. Continue to adjust each set point by repeating Steps d

and e above until all the set points have been

satisfied.

Note: The starting set point is HZ=60. Refer to the settings on Page 5.

Note: When setting the master line values on a 216 volt relay being

used on a 480 volt system, the phasing voltage necessary to close

the relay is not directly indicated. The relay calibration on this

system is determined by multiplying the master line setting by 2.2.

Refer to Table 2.

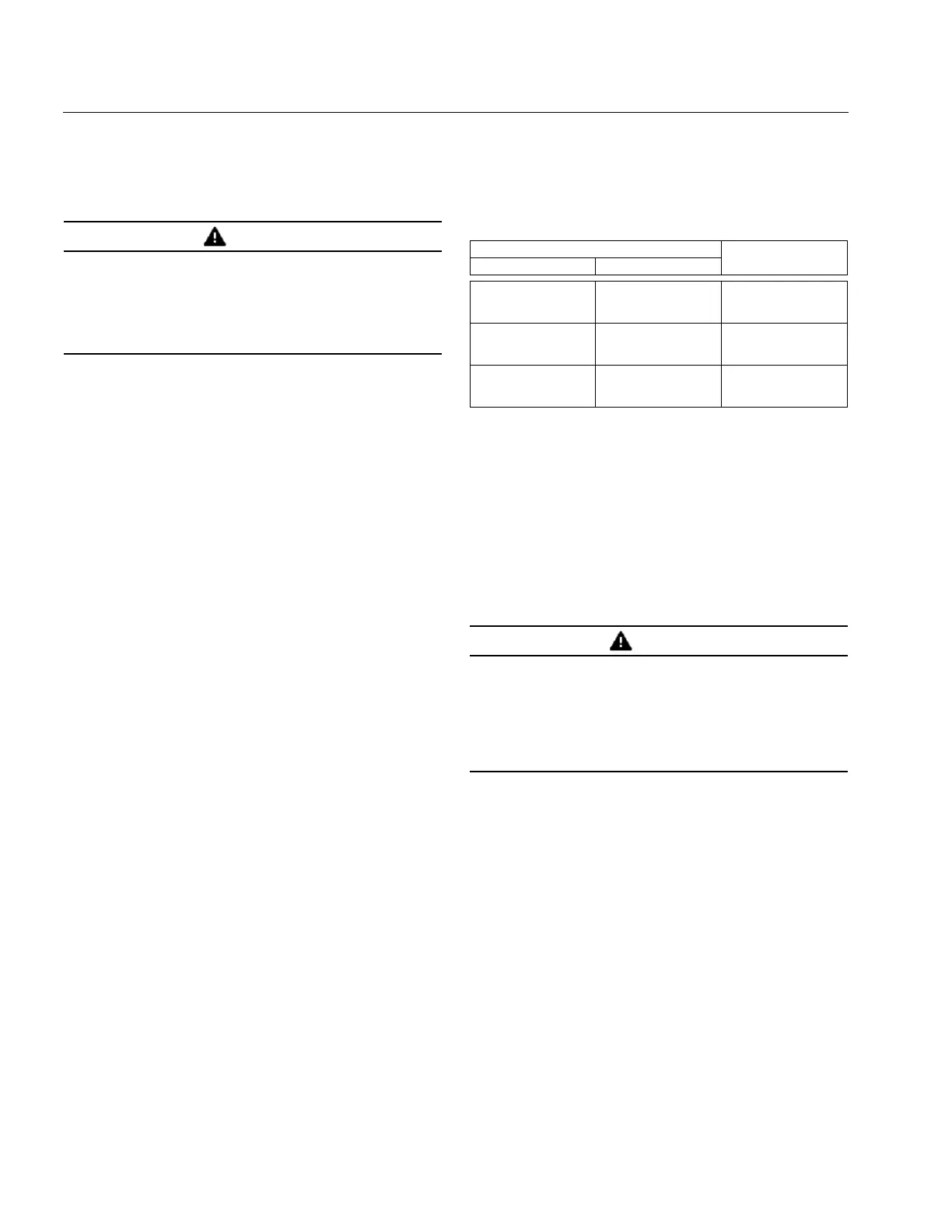

Table 2. Overvoltage Close Values for 480 Volt Units Using Potential

Transformers

Approximate phasing volts required to close the relay

contacts, in phase, equals 2.2 times the “MPC” relay setting,

Note: If the BN time delay is not required, make certain that the time

delay is set to zero (TD=0).

g. Once ALL the set points have been set, de-press the

SAVE key. The display will go blank and the float light

will remain constantly ON.

Note: If changing only one or two of the set points, the entire menu

need not be reviewed prior to de-pressing the SAVE key.

h. Remove the pendant from the relay; the relay

calibration is now complete.

Note: On all 216 volt units, the master line (ML) value equals the

phasing volts required to close the relay contacts, in phase.

WARNING

BEFORE PROCEEDING FURTHER, MAKE CERTAIN THAT THE

NETWORK PROTECTOR IS DE-ENERGIZED AND IS

WITHDRAWN FROM THE ENCLOSURE ON THE EXTENSION

RAILS. SPECIFIC INSTRUCTIONS FOR PERFORMING THESE

TASKS ARE CONTAINED IN THE LATEST REVISION OF

INSTRUCTION BOOK 1.B. 35-552. THOSE INSTRUCTIONS

MUST BE CONSULTED AND FOLLOWED.

Overvoltage Close Value Desired Master Line (ML)

Setting

At 60 Degrees In Phase

.70 V

1.45 V

2.13 V

.45 V

.90 V

1.32 V

ML = .20

ML = .40

ML = .60

2.85 V

3.55 V

4.28 V

1.75 V

2.20 V

2.60 V

ML = .80

ML = 1.00

ML = 1.20

5.00 V

5.70 V

6.40 V

3.05 V

3.50 V

4.00 V

ML = 1.40

ML = 1.60

ML = 1.80

WARNING

DO NOT FUNCTIONALLY OPERATE (TRIP AND CLOSE) THE

NETWORK PROTECTOR BREAKER WITH THE SETTING

PENDANT CONNECTED INTO THE RS-232 PORT.

CALIBRATION OF THE MPCV MUST BE MADE WITH THREE-

PHASE POTENTIAL AND ONLY AFTER THE FLOAT LIGHT IS

ILLUMINATED. AT THE END OF THE CALIBRATION

SEQUENCE, THE PENDANT MUST BE REMOVED PRIOR TO

OPERATION OF THE BREAKER.

Loading...

Loading...