92

Chapter 6 - Pump control application

POWERXL DM1 SERIES VARIABLE FREQUENCY DRIVES MN040049EN—September 2021 www.eaton.com

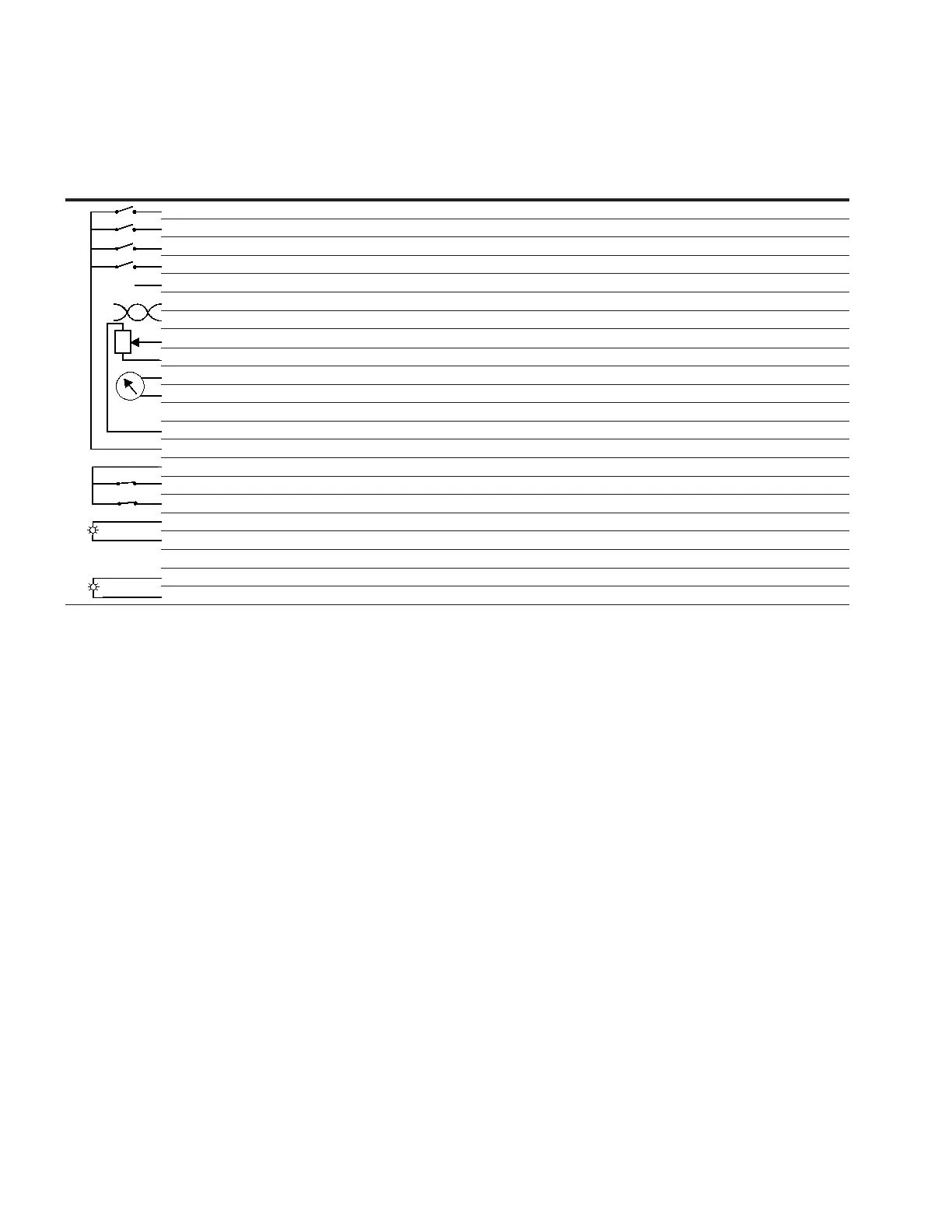

Table 36. Pump application default I/O connection (continued).

DM1 PRO

External wiring Terminal Short name Name Default setting Description

Res

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1 DI1 Digital input 1 Run forward Starts the motor in the forward direction.

2 DI2 Digital input 2 Run reverse Start the motor in the reverse direction.

3 DI3 Digital input 3 External fault Triggers a fault in the drive.

4 DI4 Digital input 4 Fault reset Resets active faults in the drive.

5 CMA DI1 to DI4 common Grounded Allows for sourced input.

6 A RS-485 signal A — Fieldbus communication (Modbus RTU, BACNet).

7 B RS-485 signal B — Fieldbus communication (Modbus RTU, BACNet).

8

AI1+

Analog input 1 0 - 10 V Voltage speed reference (programmable to 4 mA to 20 mA).

9 AI1- Analog input 1 ground — Analog input 1 common (ground).

10 GND I/O signal ground — I/O ground for reference and control.

11 AO1+ Analog output 1 Output frequency Shows output frequency to motor 0 - 60 Hz (4 mA to 20 mA).

12 GND I/O signal ground — I/O ground for reference and control.

13 10 V 10 Vdc reference output 10.3 Vdc +/- 3% 10 Vdc reference voltage.

14 24 V 24 Vdc control output 24 Vdc In/Out Control voltage input/output (100 mA max.).

15 STO_com Safe torque common — Safe torque Off common.

16 STO2 Safe torque Off 2 — Safe torque Off 2 input.

17 STO1 Safe torque Off 1 — Safe torque Off 1 input.

18 R1NO Relay 1 normally open Run Changes state when the drive is in the run state.

19 R1CM Relay 1 common

20 R1NC Relay 1 normally closed

21 R2NO Relay 2 normally open Fault Changes state when the drive is in the fault state.

22 R2CM Relay 2 common

Notes:

The above wiring demonstrates a SINK configuration. The SW2 position 1 is set to ON. If a SOURCE configuration is desired, wire 24 V to CMA and close the inputs to

ground. When using the +10 V for AI1, SW2 position 2 set to ON.

AI1+ support 10 K potentiometer.

Loading...

Loading...