21

Voltage Coil Resistance

6 DC 1.3 Ohms

12 DC 4.9 Ohms

24 DC 19.6 Ohms

48 DC 78.4 Ohms

115 DC 412 Ohms

230 DC 1680 Ohms

115 AC (60 Hz) 37 (3S) 30.5 (3) Ohms

230 AC (60 Hz) 154 (3S) 129 (3) Ohms

460 AC (60 Hz) 637 (3S) Ohms

Table 8. Coil Resistance

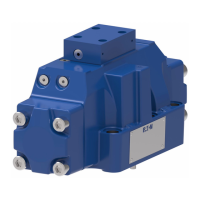

J. Assembly

Before assembly, obtain the correct seal kit as noted in the

parts drawing. Lubricate all ‘‘O’’ rings and internal parts with

clean system fluid to provide initial lubrication and facilitate

assembly.

Check the model code to determine correct assembly of

units. If a L.H. suffix appears in the model code, the pilot

valve solenoid is assembled left hand. Refer to service

drawing for parts orientation.

Assembly will be in reverse of the disassembly sequence

shown in Figures 17 and 18 unless otherwise specified.

K. General Main Stage Assembly (Refer to Figure 17)

1. Install ‘‘O’’ rings (18 and 19) on plugs (16 and 17).

Lubricate plug threads and install plugs into body (3).

Torque plugs to value noted in parts drawing. Refer to

Table 1.

2. Tap new rest pin(s) (13) into place if removed during

disassembly.

3. Install ‘‘O’’ ring (11) into ‘X’ and ‘Y’ port mounting

grooves.

4. Install ‘‘O’’ rings (12) into port mounting grooves ‘A’, ‘B’,

‘P’ and ‘T’.

5. Lubricate spool lands with clean system fluid and then

carefully install spool (10) into main body bore. Make

sure the spool moves freely inside the body bore and is

oriented properly. (See parts drawing).

Note

Spring (8) and washer (9) do not exist on spring offset ‘A’

or ‘floating’ type models.

6. Install washer (9) and spring (8) on end of spool (10).

7. Install ‘‘O’’ ring (7) into body (3) as shown.

8. Install cover (6) on body (3) with four screws (5). Torque

the screws to value noted in parts drawing. Refer to Table

1. Make sure cover is oriented properly (in line with body

contours).

Note

Repeat steps 6 through 8 for opposite side cover

assembly.

L. Pressure Centered Main Stage Assembly

(Refer to Figure 18)

1. Install ‘‘O’’ rings on plugs. Lubricate plug threads and

install plugs and set screws into body (3). Torque plugs

to value noted in parts drawing. Refer to Table 1.

2. Tap new rest pin(s) (27) into place if removed during

disassembly.

L. Check Valve Models

(Refer to Figure 18)

Note

The following step pertains to integral check valve models

only.

3. Place spring (23) into poppet (22) and then install poppet

into pressure port (P) cavity as shown. Obtain a suitable

push rod and press seat (21) into pressure port (P)

cavity. (See assembly drawing for seat orientation.) Use

an arbor press for this operation. Install ‘‘O’’ ring (20) into

pressure port mounting groove.

4. Install ‘‘O’’ ring (26) into ‘X’ and ‘Y’ port mounting

grooves.

5. Install ‘‘O’’ rings (25) into port mounting grooves ‘A’, ‘B’

and ‘T’.

6. Install ‘‘O’’ ring (24) in port mounting groove ‘W’.

7. Lubricate spool lands with clean system fluid and then

carefully install spool (9) into main body bore. Make sure

the spool moves freely inside the body bore and is

oriented properly. (See parts drawing).

8. Install piston (12), sleeve (11) and spring (10) into cover

(7).

9. Install ‘‘O’’ ring (8) in body (3).

10. Install cover (7) on body (3) with four screws (6). Torque

the screws to the value noted in parts drawing. Refer to

Table 1.

11. Install ‘‘O’’ ring (17), centering washer (16) and spring

(15) in body (3).

Loading...

Loading...