- 1 -

Safety Information and Introduction

This pump should only be serviced by a qualified person or a factory trained person.

This instruction manual includes necessary items for installation, operation and maintenance.

Read this manual carefully to ensure correct installation, operation and maintenance.

Be sure to keep this instruction manual on hand for future reference.

Design of this EBARA pump is based on superior engineering and long experience. To prevent trouble and provide

satisfactory operation and long life, it is important to understand the EBARA pump thoroughly by careful study of this manual.

If any questions arise regarding this manual, please direct them to EBARA INDONESIA.

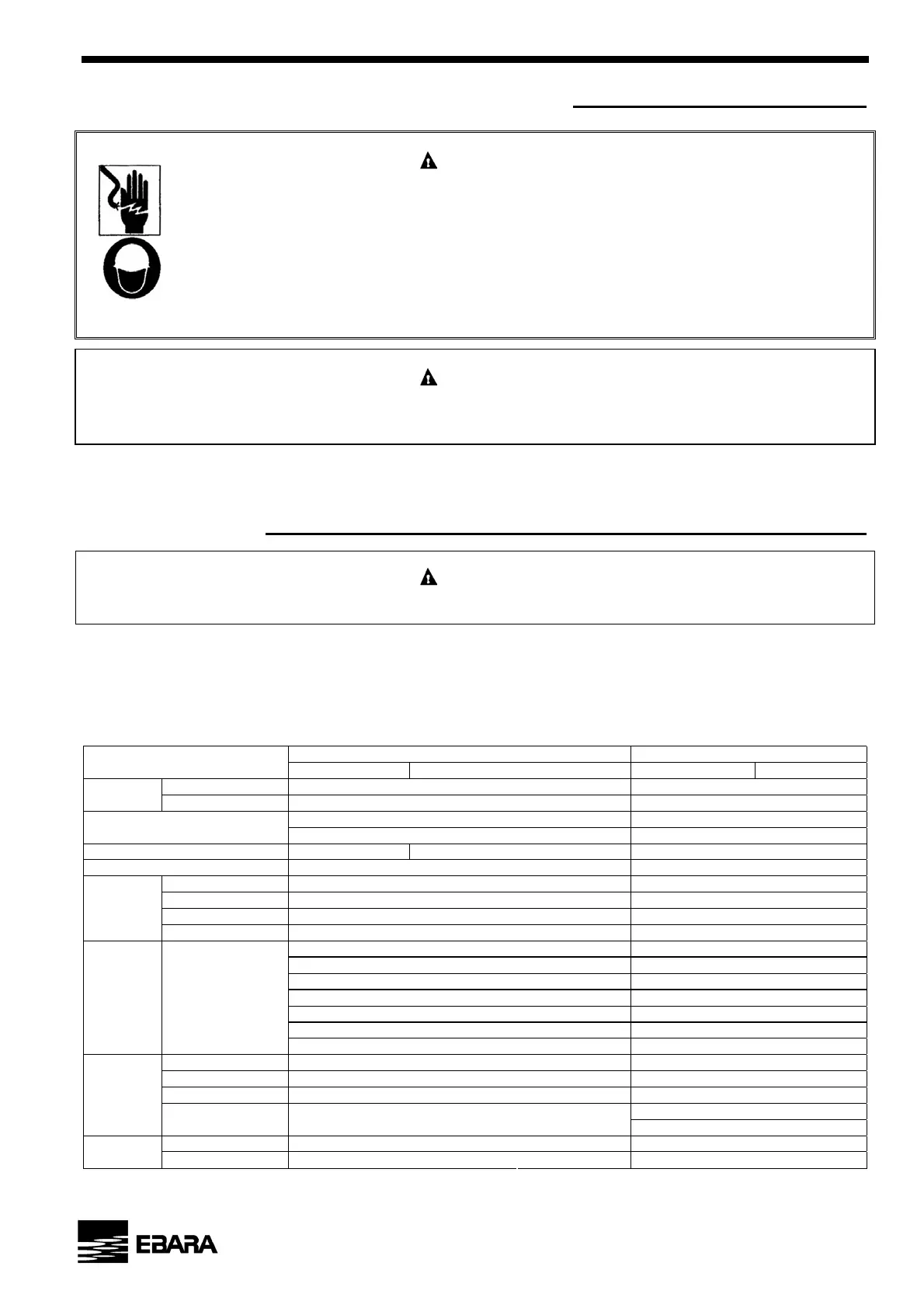

Specification

Be careful not to exceed the given specifications in the use of your products.

Check the following points upon receipt of your pump:

(1) The pump exactly what you ordered? Check the

nameplate. It is especially important that you check

whether the pump is to be used with 50 Hz.

(2) Has any damage occurred during shipment? Are any

bolts or nuts loose?

(3) Have all necessary accessories been supplied? (For

a list of standard accessories see Construction.)

We recommend that you keep a spare pump on hand in

case of emergencies. Keep this instruction manual in a

safe place for future reference.

Standard Optional

Description

2 poles model 4 poles model 2 poles model 4 poles model

Name Clean water

Liquid

Temperature

0 to 100

o

C (32 to 212

o

F)

10 bar (10.2 kgf/cm

2

) for standard flange JIS 10K RF 16 bar (16.3 kgf/cm

2

)

Max. Working Pressure

16 bar (16.3 kgf/cm

2

) for standard flange JIS 16K RF

Synchronous Speed 3000 min

-1

1500 min

-1

Installation Indoors Outdoors

Impeller Enclosed

Shaft seal Mechanical seal Gland Packing

Sealing Self flushing External flushing

Construction

Bearing

Sealed ball bearing Oil bath (some models only)

Suction < φ 150 mm, except 100x65 FSKA

: JIS 10K RF 16 bar : JIS 16K RF; DIN PN-16

100x65 FSKA : JIS 16K RF DIN PN-16

Suction = φ 150 mm, except below models

: JIS 10K RF 16 bar : JIS 16K RF; DIN PN-16

150x100 FSKA; 150x100 FSNA : JIS 16K RF DIN PN-16

Suction = φ 200 mm, except below models

: JIS 10K RF 16 bar : JIS 16K RF; DIN PN-16

200x150 FSLA; 200x150 FSNA : JIS 16K RF DIN PN-16

Flange

Suction & Discharge

Suction = φ 250

: JIS 16K RF DIN PN-16

Casing Cast Iron Ductile Cast Iron (FCD)

Impeller Bronze Casting (CAC406/BC6) Cast iron; Ductile Cast Iron (FCD)

Shaft 403 Stainless steel 304; 316 Stainless steel

Gland Packing : Teflon (PTFE) impregnated

Material

Seal

Mechanical Seal: Ceramic/Carbon/NBR

Mechanical Seal : SiC/SiC

Bare shaft Priming funnel ; valve; Companion Flange

Accessories

With motor

Common base, Coupling, Coupling guard Priming funnel ; valve; Companion Flange

Before handling this pump, always disconnect the power first. No open flame or use sparkable

electrical devices or flames in a septic (gaseous) or possible septic sump.

Do not work under heavy Suspended object unless there is a positive support under it to stop its fall in

event of sling or, hoist failure. Disregard of this warning could result in personal injury.

CAUTION

(Kg/cm

=98,6 kPa)

Note : Refer to the Standard Specification if you have purchased a standard model. We also offer pumps with optional features

according to customer demand.

Be careful not to exceed the given specification on the use of your pump.

Loading...

Loading...