24 6 INCH CHIPPER

SERVICE & MAINTENANCE

WARNING

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE, DISENGAGE THE

HYDRAULICS, OPEN SHIELD AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE STOP.

5.13 HYDRAULIC FEED MAINTENANCE

Hydraulic uid drives the feed roller. Check the uid

level daily and ll as needed. The uid and lter should

be changed and system cleaned if the uid becomes

contaminated with foreign matter (water, dirt, grease, etc.)

or if the uid has been subjected to temperatures greater

than the maximum recommended.

The hydraulic pump requires premium hydraulic uids

containing high quality rust, oxidation, and foam inhibitors.

These include premium turbine oils, API CD engine oils

per SAE J183, M2C33F or G automatic transmission

uids meeting Allison C-3 or Caterpillar TO-2, and certain

specialty agricultural tractor uids.

In the unlikely event that the oil is completely drained

from the hydraulic system, oil must be added and any air

bubbles must be purged from the system. To do this:

1. Clean all system components (reservoir, ttings, etc.).

2. Fill the hydraulic reservoir.

3. Start the engine and run at the lowest possible RPM.

4. As you purge air from the unit, the oil level in the

reservoir will drop and bubbles may appear in the

uid. Rell the reservoir as necessary.

5. Run the feed roller in both directions for several

minutes until any remaining air purges from the unit.

Rell the reservoir as necessary.

6. Shut down the engine, check for and correct any

uid leaks, and check the reservoir level. Add uid

if necessary. The hydraulic pump is now ready for

operation.

Handle pressurized hydraulic uid carefully. Escaping

pressurized hydraulic uid may penetrate your skin

causing serious injury. This uid may also be hot

enough to burn. Serious infection or reactions can

develop if immediate proper medical treatment is not

administered.

WARNING

Hydraulic pressure controlled by the relief valve is

factory set at 2500 PSI.

NOTE

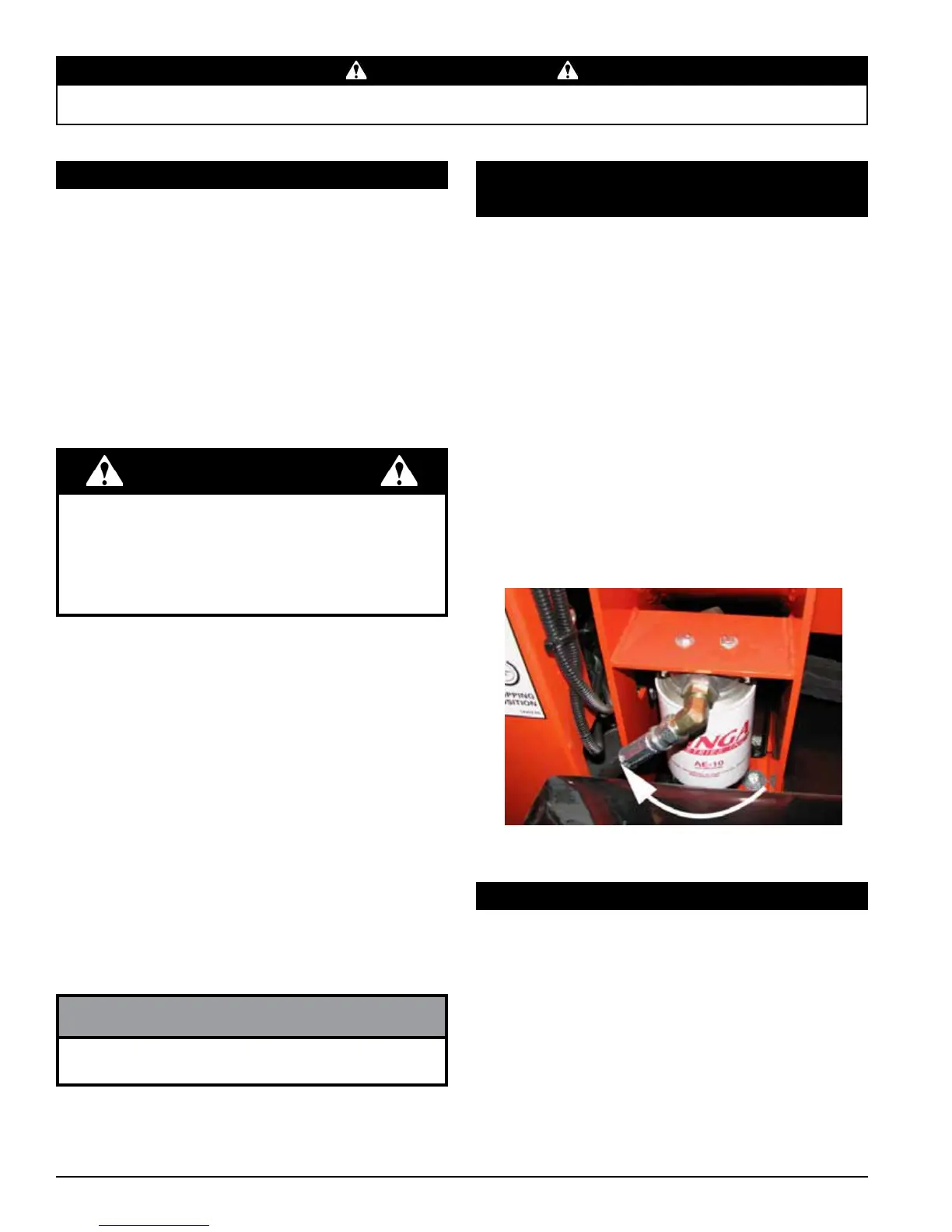

5.14 CHANGE HYDRAULIC FLUID

FILTER

Change the hydraulic oil lter after the rst 50 hours of

operation and every 200 hours thereafter.

To change the hydraulic oil lter:

1. Using an oil lter wrench, turn the lter

counterclockwise.

2. Once the lter becomes loose, turn it out the rest of

the way with your hand.

3. Properly discard old lter.

4. Lube the rubber seal on the new lter with clean

hydraulic oil.

5. Install the lter onto the threaded pipe. Turn with your

hand until the lter is nger tight.

6. Using an oil lter wrench, tighten the lter another 1/2

turn.

7. Check hydraulic oil level and ll if necessary.

5.15 CHANGE OIL

Check the oil level before each use. Change oil as directed

in the engine owner's manual.

Figure 5.9, Hydraulic Filter Removal

Loading...

Loading...