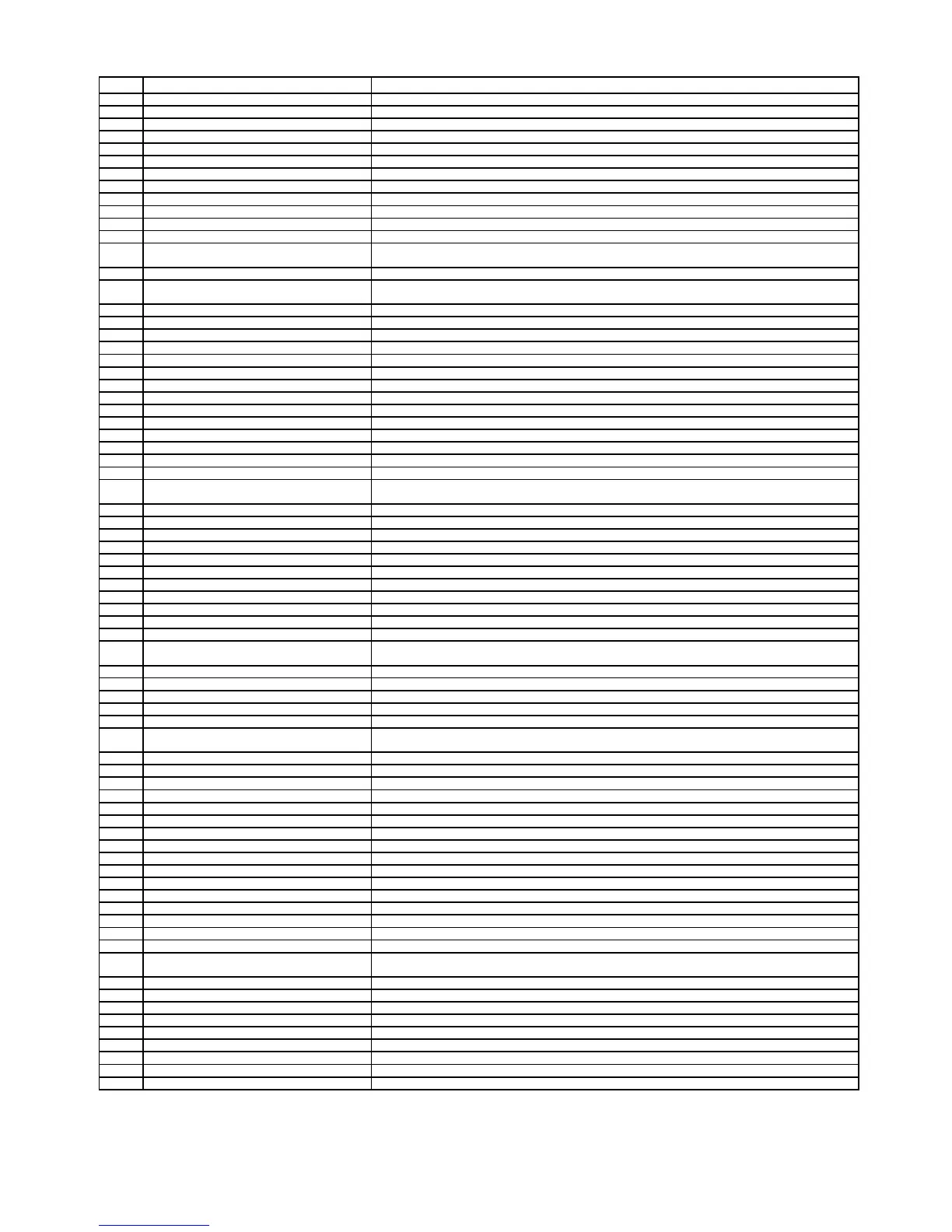

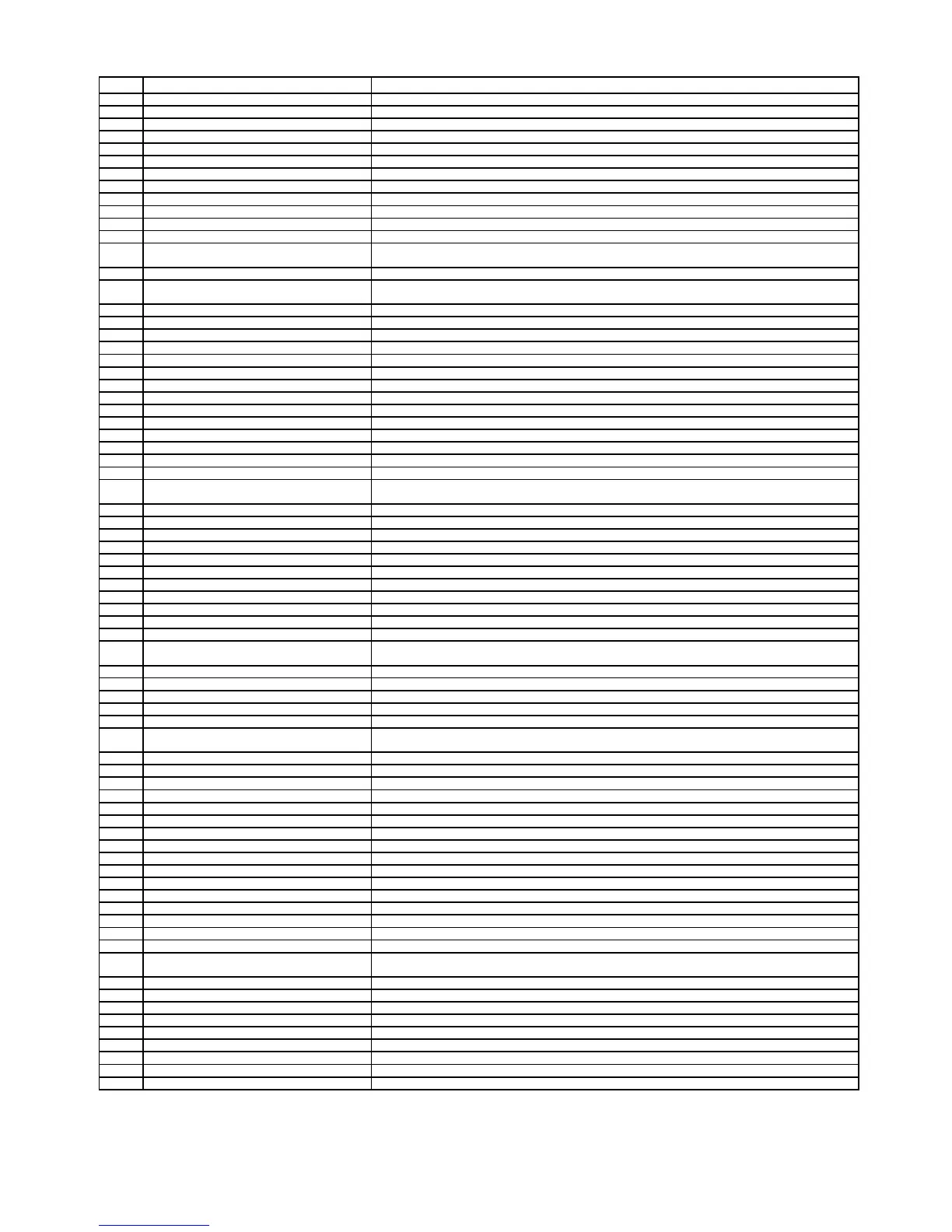

Part 14 - Troubleshooting

Supply and return switched at installation

CH set point adjusted too low

Max CH modulation set too low

Max modulation time too long

Check speed in diagnose menu (24) and check parameter 4 and 5

Boiler is not able to distribute generated heat

Check installation for sufficient flow

Check heating curve parameters 7,8,9,10

Calibration not completed correctly

Distance / gap electrode not correct

Check electrode gap and distance to burner

Ignition electrode damaged

Replace ignition electrode

Room thermostat connected incorrectly

Check cabling and connection to room thermostat

Opentherm thermostat connected

Set point thermostat (CH temperature) is lower than actual CH temperature. Check item 4 and 5 in

Thermostat does not switch off

Opentherm thermostat connected

Set point thermostat (CH temperature) is higher than actual CH temperature. Check item 4 and 5 in

Main heat exchanger cluttered

Check and clean 3-way valve when required

3-way valve does not change position

Check valve actuator and cables. Replace when required

Readout flow sensor incorrect

Check flow sensor in diagnose menu (07)

Solar tank used to feed boiler

Check availability and setting mixing valve

Setting DHW set point too high

Check DHW temperature via diagnose menu (8) and replace sensor when required

Too high DHW flow over boiler

Check use of correct (and undamaged) flow restrictor

Plate heat exchanger cluttered at CH side

Check plate heat exchanger

Gas pressure regulator stuck or broken, gas valve closed, check grid pressure

Ignition cable broken or not connected

Ignition cable cap damaged

Check for cracks. Replace when required

Ignition transformer damaged

Check if the unit sparks and check the distance and gap of the electrode. If all OK replace burner

Water in ionisation circuit

Check for water (humidity), dry and check operation. Replace when required

Check if valve fully closes when power is unplugged

Exchange sensor and check parameter 14

Wrong setting of temperature limit configuration

Check boiler power and adjust parameter 1 when required

Pump does not run is stuck

Replace pump or try to turn pump shaft.

Check cables for damage and friction free routing

Check sensor positions and connections

Check sensor in diagnose menu (4) and replace when required

Siphon cluttered (condensate cup)

Too high circulation losses or demand

Boiler is not able to heat tank to a temperature above 70C within 3 hours. Check recirculation losses and

Check cables and replace when required.

Check gas valve and replace when required.

Exchange leaking installation part s and refill

Decrease pressure using the drain valve

No temperature rise detected within 1 minute

Check position of supply sensor and flue gas sensor. Check sensor readings via diagnose menu and

after ignition or sensor broken

replace sensor(s) when required

No outdoor sensor connected

Check reading via diagnose menu (11) and replace sensor when required

Check reading via diagnose menu (6) and replace sensor when required

Check supply voltage in standby and operation

Check fan connection to burner control

Too much dust/dirt in fan

Check fan and connection and make dry when required

CH pressure sensor broken

Check reading via diagnose menu (3) and replace when required

Check reading via diagnose menu (7) and replace when required

Incorrect connection to earth

Check earth in supply cable and supply cable connections

No tank nor tank sensor present

Check reading via diagnose menu (12) and replace when required

No code key or faulty connection

Install code key and or check connections

Boiler cannot distribute heat due to high system

Perform calibration with DHW demand to be able to distribute generated heat

Calibration not successfully completed

Perform calibration and check diagnose menu (32)

Check flue pipe for blockages

Change in flue system after calibration

Magnetite filter cluttered

CH return restrainer cluttered

Clean hydro block CH return connection

Resistance in gas supply pipe too high

Check pressure drop over gas supply system too boiler. Contact grid owner when required

CH pressure sensor broken

Replace sensor. When required sensor can be deactivated temporarily. Parameter 20.

Gas / air mixture incorrect

Check fan air intake for cracks and secure placement of the air intake sticker.

Table 14.3 Possible causes and solutions

72

Loading...

Loading...