D395-90-880 Issue E

Page 18 © Edwards Limited 2010. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

MAINTENANCE

5.3 Cleaning the controller

If necessary, use a soft dry cloth to clean the exterior of the Controller. Do not clean with harsh abrasives or liquids.

5.4 Software upgrade

As new compatible gauges are released, a software upgrade for the ADC might be necessary. If you have purchased

a new gauge which is not listed in Table 1, and the display shows "???" when the gauge is connected, then you may

need an upgrade. Please contact Edwards for details, quoting the serial number and the software version number of

the ADC. The software version number is shown on the display during power-up, in the form "AdCxx".

5.5 Calibration service

A calibration service is available for all Edwards Controllers and gauges. If you require a calibration certificate for

your ADC, please contact Edwards.

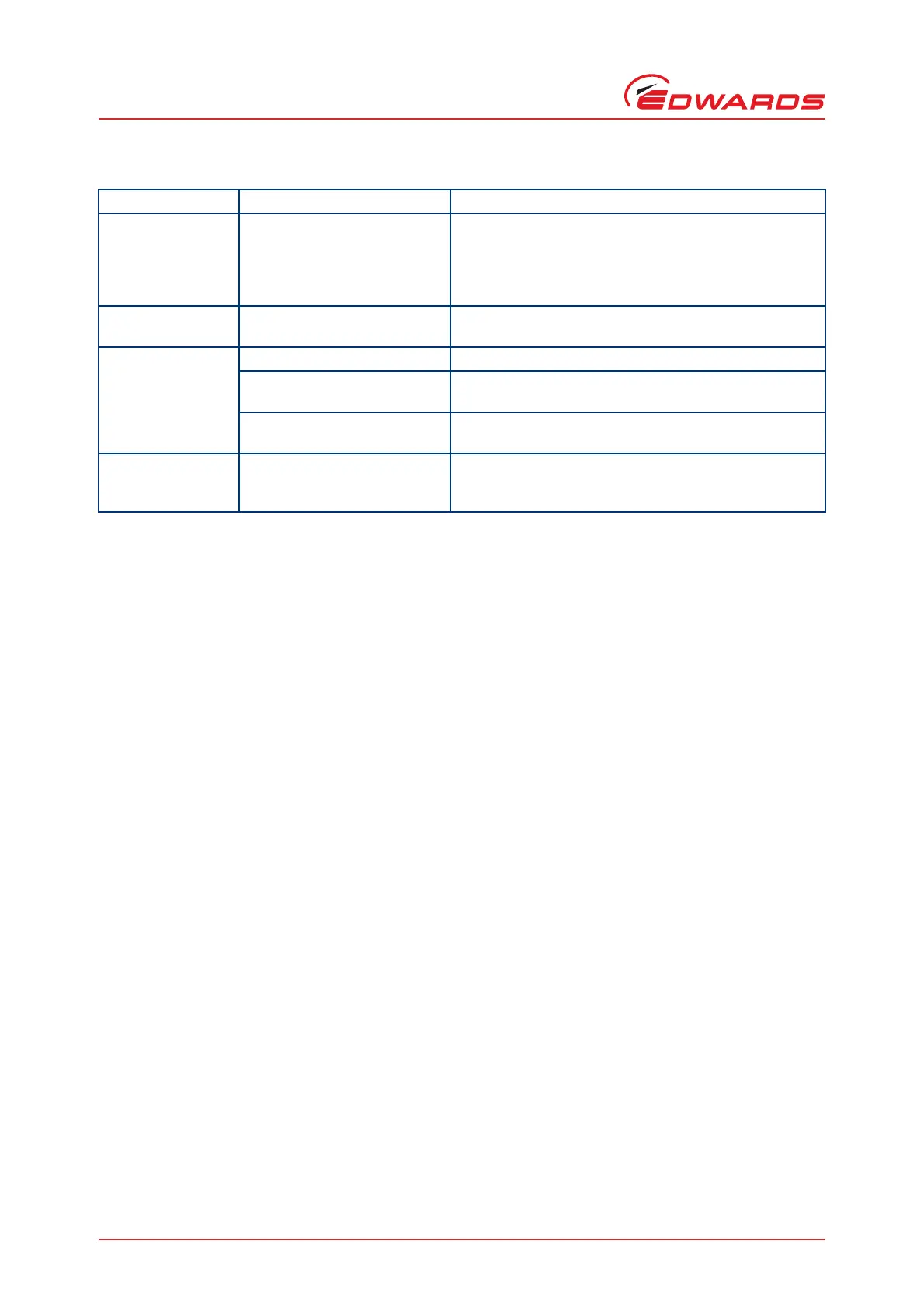

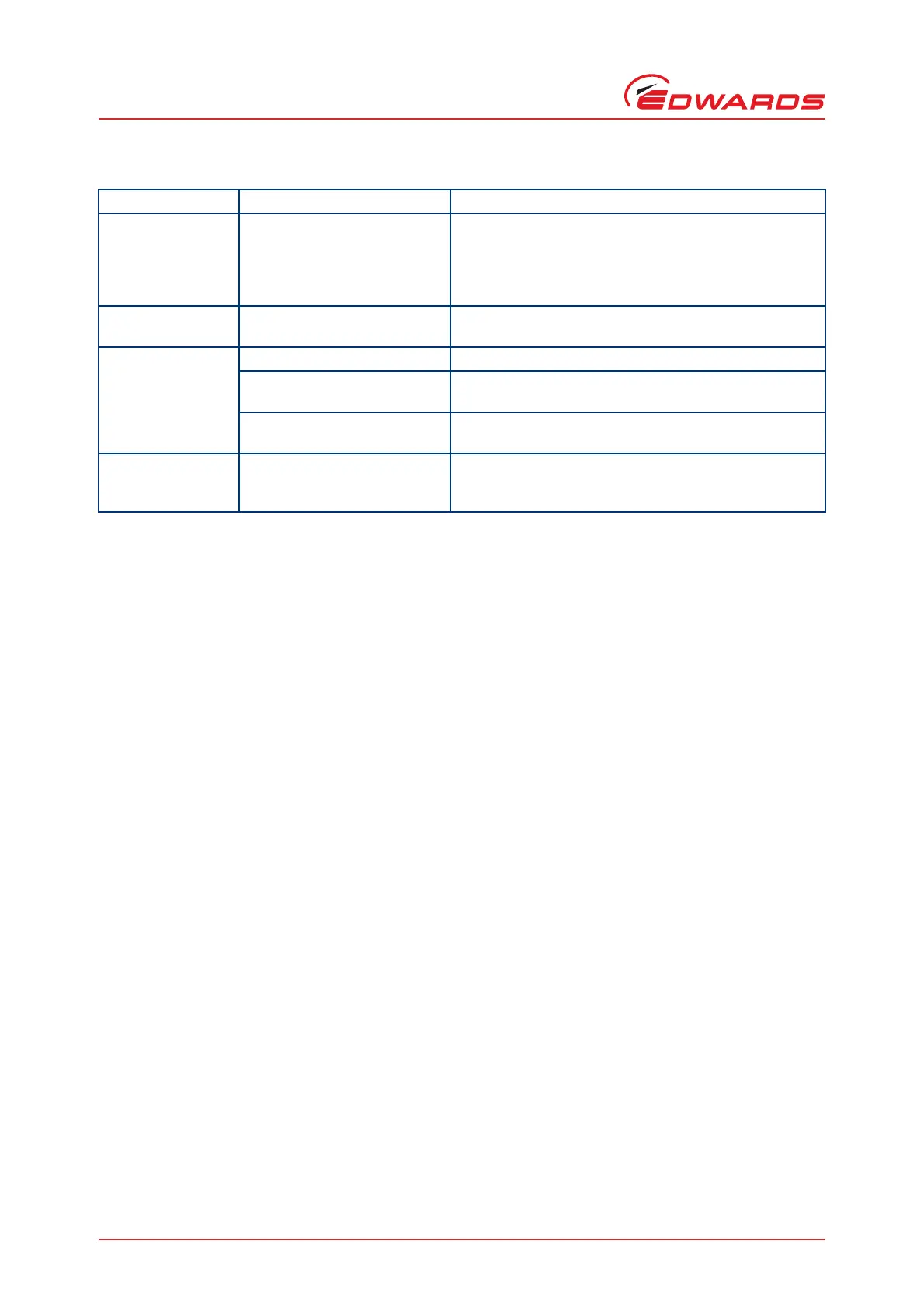

Chart recorder

output voltage not

as expected

Excessive loading on output Set the ADC into voltage display mode (see Section 4.5.5)

and compare the displayed voltage with the output

voltage. If they are different then the loading may be

incorrect. Check the connections and compare with the

specification in Section 2.5.2.

Relays chattering Insufficient hysteresis Adjust the set-point low threshold lower or adjust the set-

point high threshold higher. See Section 4.2.1.

RS232 no response Cable wiring incorrect Check that the wiring agrees with Figure 8 or 9.

Protocol on master does not

match ADC

Check that the master is set to 9600 baud, 8 data bits,

1 stop bit, and no parity.

Handshaking selected at master Check that no handshaking is selected. ADC does not

support CTS/RTS and Xon/Xoff.

RS232 erratic Message rate too fast Ensure that the master is not sending more than

3 messages per second. Wait for reply from the ADC

before sending another message.

Table 11 - Fault finding guide (continued)

Symptom Possible cause Remedy

Loading...

Loading...