A371-32-880 Issue C

Page 20 © Edwards Limited 2007. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

5.3 Check the oil-level

Note: If required, you can check the oil-level while the pump is operating, however you must switch off the pump

and isolate the pump and other components in the pumping system from the electrical supply before you

pour oil into the pump.

Refer to Figure 1 for the items in brackets.

1. Check that the oil-level in the sight-glass (7) is between the MAX and MIN level marks on the bezel of the sight-

glass.

2. If the oil-level is near to or below the MIN level mark, remove the filler-plug (4) and pour more oil into the

reservoir until the oil reaches the MAX level mark. If the oil-level goes above the MAX mark, remove the drain-

plug (9) and drain the excess oil from the pump. Refit the filler-plug.

3. If the oil is contaminated, drain and refill the pump with clean oil as described in Section 5.4.

5.4 Replace the oil

Refer to Figure 1 for the items in brackets.

1. Operate the pump for approximately ten minutes to warm the oil, then switch off the pump. (this lowers the

viscosity of the oil and enables it to be drained from the pump more easily).

2. Isolate the pump from your electrical supply and disconnect it from your vacuum system.

3. Remove the oil filler-plug (4).

4. Place a suitable block under the pump-motor to tilt the pump and place a suitable container under the drain-

plug (9). Remove the drain-plug and allow the oil to drain into the container.

5. If the oil is dirty or contaminated, pour clean oil into the pump and allow it to drain out of the pump. Repeat

this step until the oil reservoir is clean.

6. Refit the drain-plug, remove the block and reconnect the pump to your vacuum system.

7. Fill a suitable container with clean oil and pour the oil into the filler hole until the oil-level reaches the MAX

level mark on the bezel of the sight-glass (7).

8. Allow a few minutes for the oil to drain into the pump. If necessary, add more oil. Refit the filler-plug.

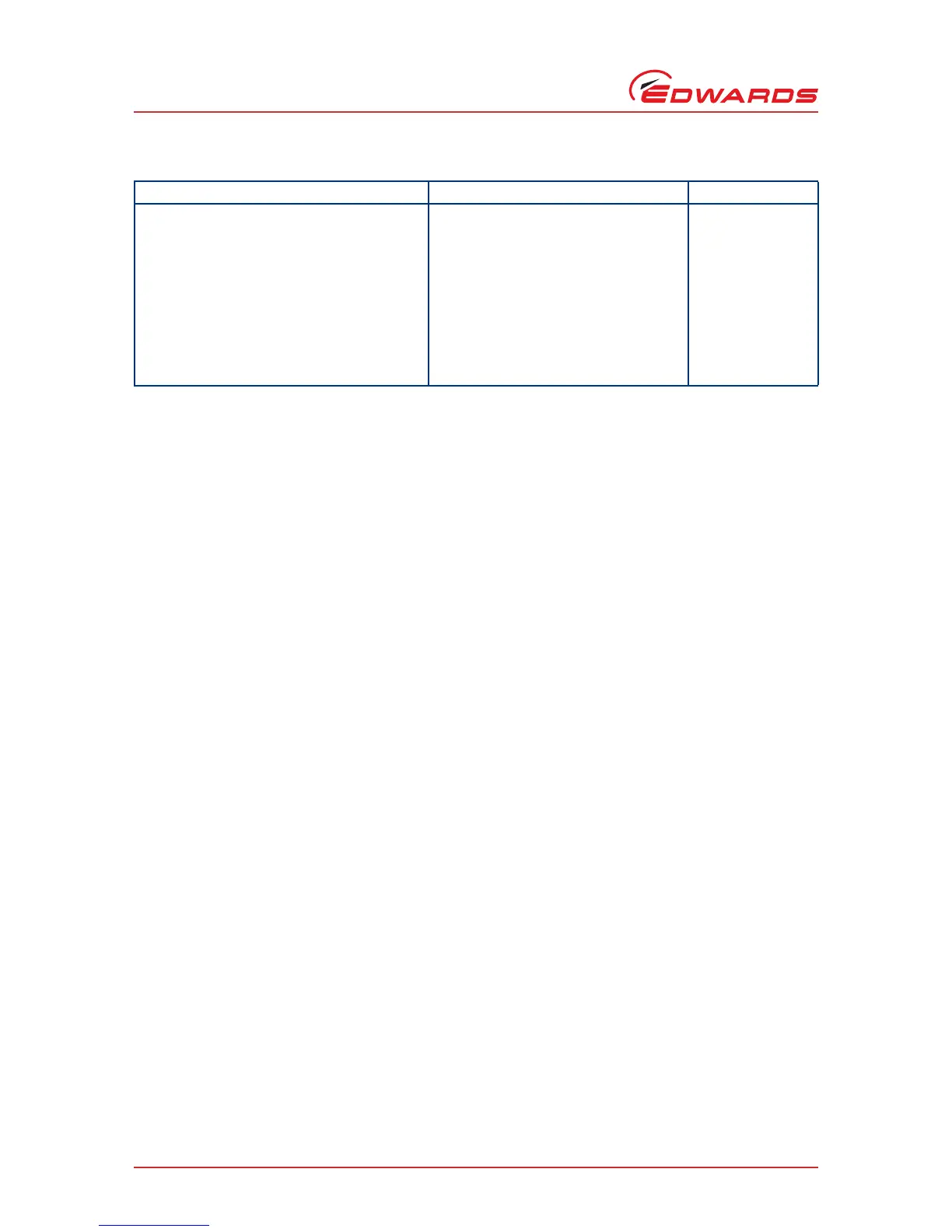

Table 4 – Maintenance plan

Operation Frequency Refer to Section

Check the oil-level Monthly 5.3

Replace the oil 3000 operation hours 5.4

Inspect and clean the inlet-filter Every oil change 5.5

Clean or replace the gas-ballast o-ring Every oil change 5.6

Clean the motor fan-cover Yearly 5.7

Clean and overhaul the pump 15000 operation hours 5.8

Fit new blades 30000 operation hours 5.9

Test the motor condition 15000 operation hours 5.10

Loading...

Loading...