© Edwards Limited 2007. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

A371-32-880 Issue C

5.11 Fault finding

A list of fault conditions and their possible causes is provided here to assist you in basic fault-finding. If you are unable

to rectify a fault when you use this guide, call your supplier or your nearest Edwards Service Centre for advice.

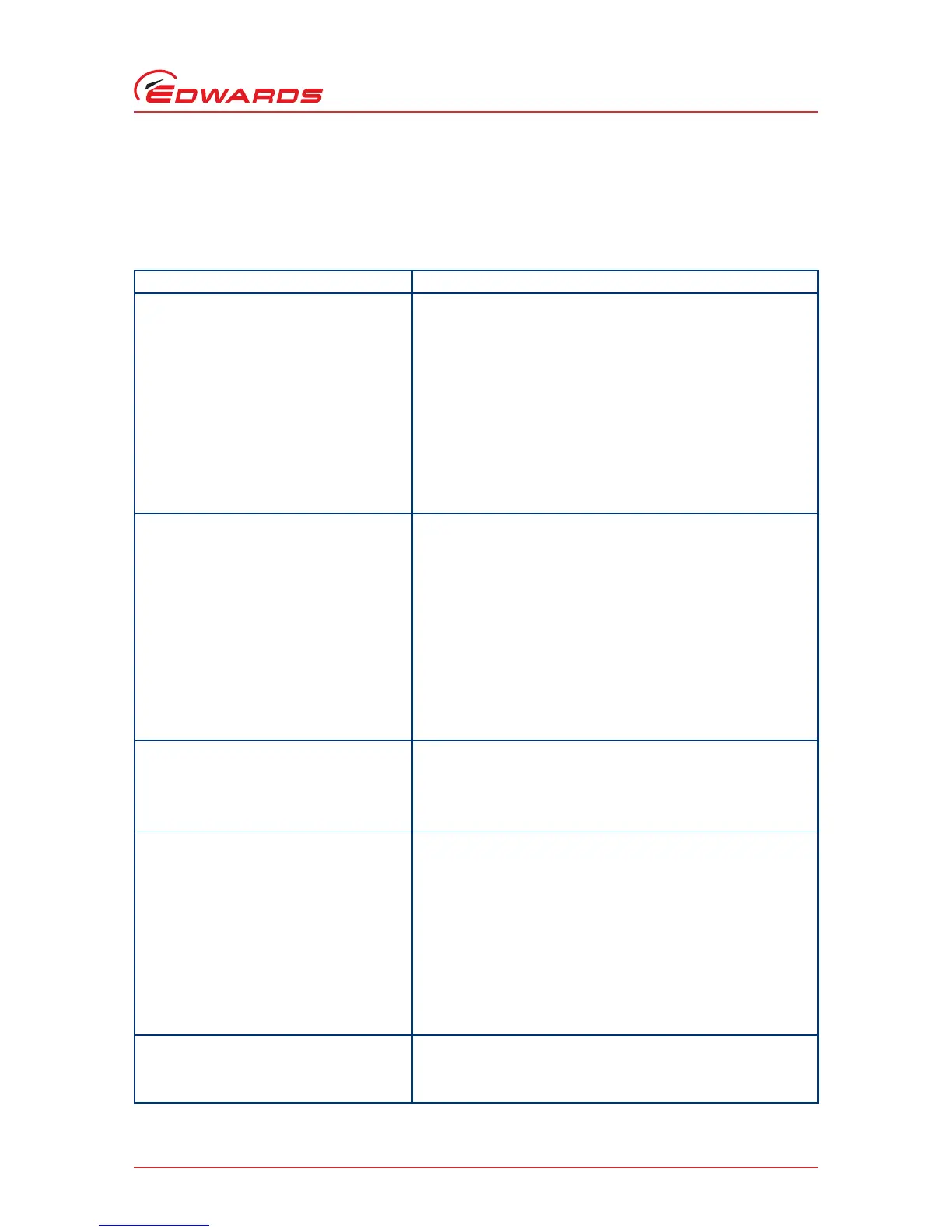

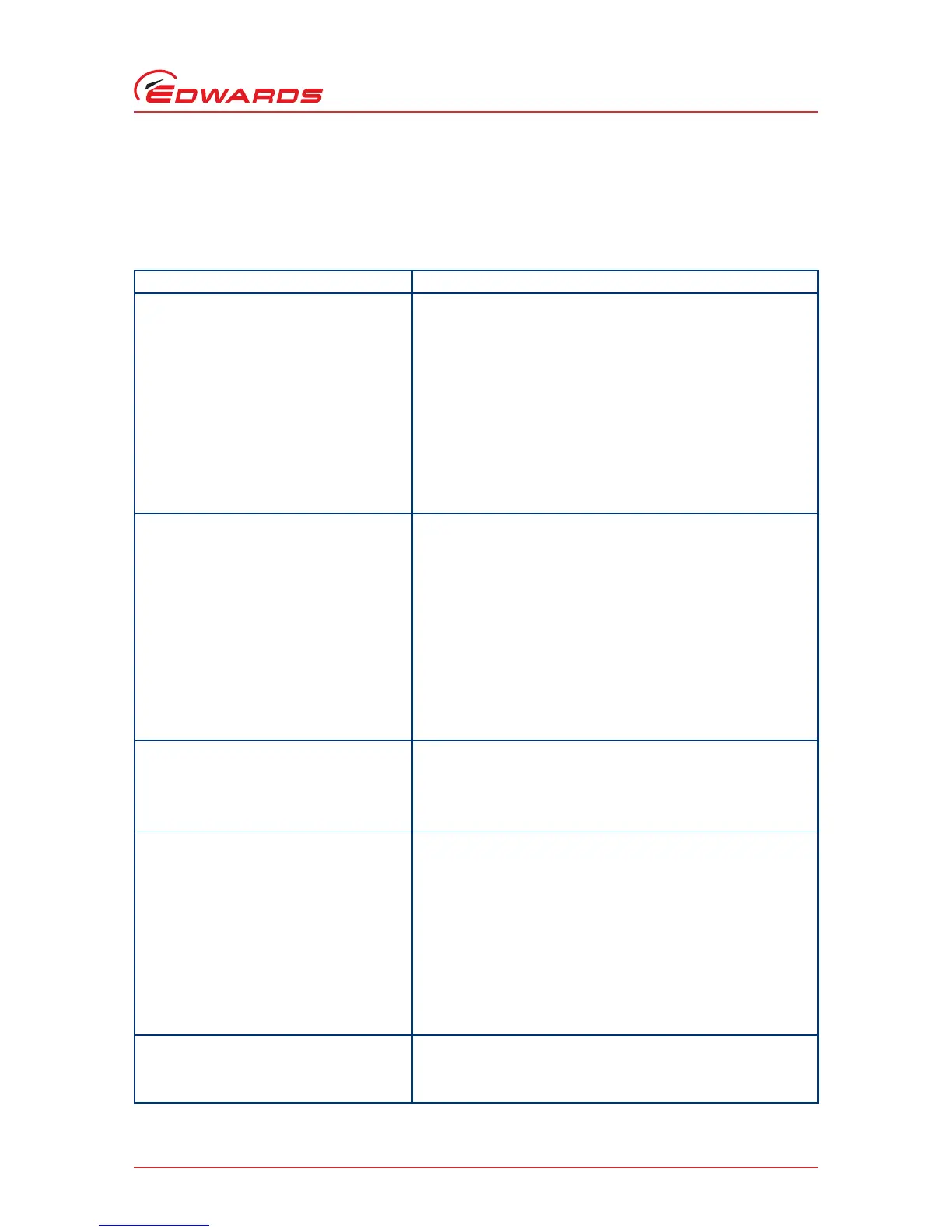

Tab le 5 – Fau lt f i n d i ng

Fault condition Possible cause

The pump has failed to start The electrical supply fuse has blown.

The motor is incorrectly wired.

The operating voltage does not match that of the motor.

The exhaust filter or exhaust line is blocked.

The oil temperature is below 12 °C (53.6 °F).

The oil is too viscous.

The oil is contaminated.

The pump is seized after long storage, or has been left to stand

after pumping contaminants.

The motor is faulty.

The pump failed to achieve specified

performance (Failure to reach ultimate

vacuum)

Your measuring technique or gauge is unsuitable.

There is a leak in the external vacuum system.

The gas-ballast control is open.

The oil level is too low.

You have filled the pump with the wrong type of oil.

The oil is contaminated.

The pump has not primed.

The vacuum fittings are dirty.

The inlet-filter is blocked.

The pump has not warmed up.

The pump is noisy The motor fan-cover is damaged.

The motor bearings are worn.

The oil is contaminated with solid particles.

One of the pump blades is sticking.

The pump surface temperature is above

100 °C (212

°F)

The ambient temperature is too high.

The cooling-air supply is insufficient or is too hot.

The cooling-air supply is blocked.

The electrical supply voltage is too high.

The exhaust filter or exhaust line is blocked.

The oil level is too low.

The pump is filled with the wrong type of oil.

The oil is contaminated.

The process gas is too hot, or the throughput is too high.

The vacuum is not maintained after the pump

is switched off

The gas-ballast control is open.

O-ring(s) are damaged or missing.

The shaft seals have deteriorated.

Loading...

Loading...