9|\||>|9|M;\g '|v/\Q|/\|33

33¢]-193 -1-|/\ a.|n5!=|

q|nq

wnnoe/\

e sapnpug

luawdgnba

pa1gnba1

aq_|_

'SS8OOJd

l.'l/\

8|dLU[S

e sg

J3/\OlJJ3.l-J8[I)|OS e

;o sueaw

Aq 1ap|os

6ug/\owag

ll

I

F -—

r,

_

.1L_

pt;

I

-

|

Q

-It-7-‘P?

u

--

f

' /

____

|

L#

(]0HJ.ElW

's/v\o||o;

qaea

;o UO!1d!.lOS8p

;agJq

V

--

_

's1|nse1

p006

a/\g6 sp01.|1au1

qlog '”>|0g/v\,,

e ;0 asn

amp, 1aq10

/

‘ ~»...§\

sq), pue 'J9AOlLl8J 1ap|os pa1e1ado

q|nq LUHHOQA

e 40 asn

sq), s|ge1ua

aug "pad e UJOJ].

J9p|OS aql

a/\0u.1a1 01 pasn

aq

"a;-___

uea

SpOL{l9LU

o/v\1 ;o auo

1aq1g3 "awn

a|qe1apgsu0o sa1gnba_1

|n;a1e0 Anegaadse aq ‘1uawa:)e|da1

10 uogloadsug

Jo; p1e0q

13,3

1_!nO.l!i)-p91U[Jd e LUOJ} pa/\ou1a1 we

S1U8UOdU.JOO

Aue

;|

‘

A|uea|:>

S1U8UOdL1JOD

a/\0wa1

oi "H0; sq],

aewep 01

10u

‘,0

§

&--—-—

E)NlHElCI'|OS

.Ll3HlO

(]El.LNlHd

8'9

'1ep|0s

40

aaJ;ee1e

1ug0[

aql Bug/\ea| ’>|:>!/v\ aql dn

/\|>|0gnb /v\0|; pue 1|aw ||g/v\

1u!0[

'P91l"5U°9

aq P|"°l-I5

'9J"P9°°Jd

luau‘

eql

ug1ep|os

aq1,\0

lsow

’spu00es M9}

e

u!L|1!/\/\

'pa1ap|osun

-U5!|V

9'41 '/\

U°!199S '51U9U°dW°9'W!11

19!}!ldW9

9111

4°

aq

01 1ug0[

aql

a/\oqe

/\|10eJgp

a1!/v\ papuens

aqn,

;0

9W051$n[P9

01

/9955999“ 9‘?! Alqeqold ll!/V\

1! 'P919ldW°°

9!

do1

uo U01! 5U!J9p|OS

loq 9 a0e|d

‘L-|/\ em6g:|

ug u/v\oqs

sv

$1U9U0dL1109

P9‘?!

J0 1U9W999|d91

PUB

5U!1°°LI59lqn°11

U9L|N\

'xn|,1 eseq-pgoe

'(J911!W9

ue asn saouelswnznga ou

Japun

:3_|_Q|\|

'1ugo[

8L|1

JGAO

9H1

01 l99d$9J

LI1!/V\ P91"$99W]' 9591|°/\ 95%|

9H1

UPLI1 559i

/v\0|;

01

xn|; aql ;0 awos Bu!/v\o||e ‘peuap osun

eq 01 1u!0[

5!1°1$!5U9J1

P9l9Jn195 9 J0 959140/\

1°199l|°9 9H1 19LI1

PL"? '/\

9L|1

40

dO1

uo

pgeuq

10 91!/v\

eql

aoe|d

uaq_|_ '><n|; 6ug1ap|os

9'0

/\lLl5"°1

5! (U°!19U"! 9P°!P 1°)

J°1'5!5U911

U°9!l!5

P999!q

889C]-Ll!SOJ

eql o1ug

pgeJq 6ugp|egqs

10

cu!/v\

pepueus

40

P19/‘M01949

9591|°/\

1911!ll-'9-01-95'?q

QLI1

lelll Jaqwalllal 01

saqaug Ma; e

dgq :sAAo||o;

se

peaawd '(1ue|e/xgnba

JO gg-917$

In-J99"

9!

1!

'5>I99Ll9

959l|0/\

5U!°P

9|!LllV\

"5U°!19U"!

J°199il°9

V|_|d"|V)

xn|;

6u!1ap|0s

aseq U!SOJ awos pue 'p!BJC]

papuens

PUP

eseq

8L|l

40 U0!1OB

epO!p

9L|1

5LI!>i09L|0

Aq J01S!$LIBJ1

peq

4Q Alddng Q ’(1u9||9QX3

5! pgqlgw

U! pgpugwwgggj lgql)

9 91BOO|

O1

a|qgssod

S8lil!l8LUOS S! 1!

'S)|O9L{O

8OU€lS[S9J

5Ll!Op

um! 5ug1ap|0s

p006 B sapnpu!

pa1gnbeJ

luauudgnbg 'poq1eu1

U9L{/\A

'8|qn0J1

eql 1u!0du!d

/\||BO!,l!09dS

ueql

UBO $>|0€-M10

sgql

Aq pa/\agq0e aq ueo >|1o/v\ ueap A||eu0g1de:>x3

‘pad

9L|1

99UB15!$9J

PUB

95Bl|0/\

’1!n9J!0

PBOIJI-J/\0

8L|1

01 JO $85918

uu0J;1ap|os ua1|0w

aql dn

/v\e1p 01 >|:>g/v\ e se pgwq

6ugp|e!qs

J9!}!|dLUB

9L|1 40 BUO O1

e|qno11

Bql 819|0S!

S>|09L|0 |9u5!$

10

a1!/v\ pepue11s;0 q16ua| e sasn

qagq/v\ poqlew

2 sg 6ug>|ogN\

181}V 'S|Bu5!S

lndul

1Su!B6e

s|eu6gS

1nd1H0

5u!J9dw00 /\q

pa>|oeqo

aq Aew saels

.l9[}!|C|LUE?

0*/v\1 aql ‘sa6e1|0/\

A|dclns

z# qQ|_|_|_3W

.l9N\Od

aql 6ug>|oeq0

.l9l}V 'a|qnoJ1

aql 6ug1e|osg

10; uoglew

-J0;u!

1uag:)!;;ns

Sp!/\O.ld p|noqs '(||/\

uogloag)

soglewaqos

.S9|OL|

pue

suuwegp

1noAe|

a'q1 qlg/v\

1aq1a601 'UO[ld[J3S8(]

lgnzugg

aql

mum;

.l8p|OS ||é

Jeep

/\|a1a|duuo0

01

JGAOLUSJ

J8p|OS W1

I/\| “Q9393 'sw°1d‘“’\5

mil 5u!u!‘*“919p

U! |n¥d|9L| aq

am asn

Ipamwal uaaq seq luauodwoo

am JGHV

.pJeOq

||g/v\

'|| UO!1Q8S'S>|O3L|Q

|eg1gu|

ug ua/\g6

e1npa:>oJd

pue dn-1as

a\.|1 mum;

sea; sg luauodwoo

aql

|!1un

speag

ea1,Lun

aql

9L|i'p91S91 pug

pamauuoa Auadold S!

J9!=‘!|dwB am “WM

40

qsea 10;sgq1

5U!1B9d9J

/\|a/xgssaoons

pue

‘a|qgss0d se Je; se

SWQWW/\$

9H1

U!B1J99SB

pue

'9|C|O.l1

aq1

5,0

sasneo

|eu1a1xa

aloq am

qnoml peel am ‘Ind

O1 luauodwoa em Huppojn

Aue

au!uua1ap

01 A11 'SS9OOJd

6ug100qse|qn0J1

aql paads o_|_

pue spea|

aql 40

auo

01

leaq

ug/\|dde

Aq

pa/\0wa1

eq

ueo luauoduuoo

aql ‘sa|oq

aql

ug spea| aql

;0

||e em;

3UnC|3QOHC|

2'9

01 a|qgssod

1ou

sg1g;g

5/\|snoeue1|nLugs

sa|0q

aql ug

am; spv2a|

s1! ;0

||e

a/xeq

1SI'1LLl awgl

e 1e auo

PGAOLUBJ

aq 10uue:> qogq/v\

Vuueuem aw’

a1Bp!|e'\u! pmoa Os

Speal LIMA luauodwoo

V _9|Oq am mo“

peel am Bumnd

op 01 am|ge;se‘1gede1

p|a!; e Bugldwane

01 JO‘_\.lC|

paloeluoo

a|gL|/v\

leeq

A|dde

01

anu!1u0o

‘am;

-lou

sg pee|

aql

;|

'SJ8[|d

sq 9A!]'e1uaSeJd9J

@0139} paZ!JOL|1ne

ue leql luelmdw!

asou-6u0|

a|qe1gns

ugsn

‘pmoq

aql

,10

apgs luauodwoo

/Welnagljed

S! 1! A-LNVHHVM

U! “us S! luewmlsu!

am won eloq am qnojul

peel am ‘Ind ,pa/mwaj

8L|1 ,1! eseo Aux?

u|

ugedeu

JO}

M0102;

aql 01 1; 6ugum1a1

1ap|os

eql 1a1;V

'/Uessaaeu

ueql 1a6u0|

Aue

1eaq 01

10u ems O1

pasoddo Se Haswm

luawmlsu! aw’ Bumedaj

JO swam

e>|e_|_

'a|oq pue

ped sq),

LUOJ} 1ap|0s

sq),

8/\OLL|9J 01

J9/\OLU9.l 9A!]'e'aJ aw’

U0 a3!Ape JO} uonejodjoa

“M98895 pauddv

Jeplos am

asn ,SMOH

_1uauOdwOO

uolaoupd

19e1u0:>

p|noqs JGSH

aq1 5u!10oqse|qn0J1

Aue

eql allsoddo

ems aql ped

5U!lC|lU811B

9JO}9C]

JO 1U8UOdllJOO JO

l!I'\OJ!O O!].!O8C|S B O1

paeomd

‘luauodwoa

e a/\0wa1

O_|_

'1uauodw0o

HLI1

allsoddo

pelmos!

S!

walqojddaql

8?/:0

-lmdlau 9/(2 “W25 uonoas

SM1 U!

ems am

U0 ped am won pamwaj

aq lsmu Japlos

aql _(d!1 pau!|1no

sampaom 8L|1. JBSSBOSU

aq

ew u!100qsa|qno11

SNVLM

ad/Q WM OZLOVSGHVL

ad/£1 TIVM)

J3/mod |euo!se:)00‘1uawnJ1suga|qeg|aJ

e sg 311

|ap0|/\| aqn, q6n0q1|v

-po1.u,10

um! 6ug1ap|os

p006

e pue

(papuewwoam

(_'1‘08L#

:|;|()-H3Q|"|()S

ad/£1

av-§)|\|(])

.l9l\OUJ9J

1ap|0s

pa1e1ad0 N()|J.QC|0H.].N| L 9

9Nl.l.OOHS3'l8OH.l.

lI\

NOILOHS

32

Q

D

‘\\

J

(

SECTION

VI

TROUBLESHOOTING

6.1

INTRODUCTION

Although

the

Model

113

is

a reliable

instrument,

occasional

troubleshooting

may

be

necessary;

the

procedures

outlined

in

this

section

will be helpful.

Once

the

problem

is

isolated

to

a specific

circuit

or

component,

or

before

attempting

any

troubleshooting,

the

user

should

contact

Princeton

Appl ied Research

Corporation

for

advice

on

the

relative

merits

of

repairing

the

instrument

himself, as

opposed

to

returning

it

to

the

factory

for

repair.

In

any

case, if

the

instrument

is

still in

WARRANTY,

it

is

particularly

important

that

an

authorized

factory

representative be

contacted

prior

to

attempting

a field repair,

as

failure

to

do

so

could

inval

idate

the

Warranty.

6.2 PROCEDURE

To

speed

the

troubleshooting

process,

try

to

determine

any

external

causes

of

the

trouble,

and ascertain

the

symptoms

when

the

amplifier

is

properly

connected

and

tested.

The

set-up

and

procedure

given

in

Initial Checks,

Section

II, will

be helpful in

determining

the

symptoms.

Section

IV,

the

Circuit

Description,

together

with

th.e

layout

diagrams and

schematics

(Section

VII),

should

provide

sufficient

infor-

mation

for

isolating

the

trouble.

After

checking

the

power

supply

Voltages,

the

two

ampl ifier stages

may

be

checked

by

comparing

output

signals against

input

signals.

After

signal

checks

isolate

the

trouble

to

one

of

the

amplifier

stages

or

to

the

overload

circuit,

voltage

and

resistance

checks

can

then

specifically

pinpoint

the

trouble.

When

doing

resistance

checks,

it

is

sometimes

possible

to

locate

a

bad

transistor

by

checking

the

diode

action

of

the

base and

collector

junctions.

Wh

ile

doing

voltage

checks,

it

is

usefu I

to

remember

that

the

base-to-emitter

voltage

of

a

forward

biased silicon

transistor

(or

diode

junction)

is

roughly

0.6

V,

and

that

the

collector

voltage

of

a

saturated

transistor

is

less

than

the

base voltage

(measured

with

respect

to

the

emitter).

When

troubleshooting

and

replacement

of

bad

components

is

completed,

it will

probably

be necessary

to

adjust

some

of

the

amplifier

trim-components.

Section

V,

the

Align-

ment

Procedure,

should

be

consulted.

6.3 PRINTED CIRCUIT SOLDERING

If

any

components

are removed

from

a

printed-circuit

board

for

inspection

or

replacement,

be especially careful

not

to

damage

the

foil.

To

remove

components

cleanly

requires

considerable

care_

Either

one

of

two

methods

can

be used

to

remove

the

solder

from

a pad.

One

entails

the

use

of

a

vacuum

bulb

operated

solder

remover,

and

the

other

the

use

of

a

"wick".

Both

methods

give

good

results.

A brief

description

of

each

follows.

METHOD

#1

Removing

solder

by

means

of

a

solder-remover

is

a simple

process.

The

required

equipment

includes a

vacuum

bulb

VI-'

operated

solder

remover

(UNGAR

type

SOLDER-OFF

#7805

recommended)

and

a

good

soldering

iron

of

mod-

erate

power

(WALL

type

14HDG40120

with

type

W14KS

tip).

The

solder

must

be removed

from

the

pad

on

the

side

opposite

the

component.

To

remove a

component,

proceed

as

follows:

Heat

the

pad

on

the

side

opposite

the

component.

As

soon

as

the

solder

flows, use

the

solder

remover

to

remove

the

solder

from

the

pad

and

hole.

Take

care

not

to

heat

any

longer

than

necessary.

After

the

solder

has

been

removed, pull

the

lead

through

the

hole

from

the

component

side

of

the

board,

using

suitable

long-nose

pliers. If

the

lead

is

not

free,

continue

to

apply

heat

while

pulling

the

lead

from

the

hole.

A

component

with

leads

which

cannot

be removed

one

at

a

time

must

have all

of

its

leads free in

the

holes

simultaneously;

if it

is

not

possible

to

free

all

of

the

leads in

the

holes,

the

component

can be

removed

by

apply ing

heat

to

one

of

the

leads and

"rocking"

the

component

to

pull

the

lead

through

the

hole

as

far as possible,

and

successively

repeating

this

for

each

of

the

unfree

leads until

the

component

is

free

from

the

board.

After

the

component

has been

removed,

use

the

solder

remover

to

completely

clear

all

solder

from

the

holes.

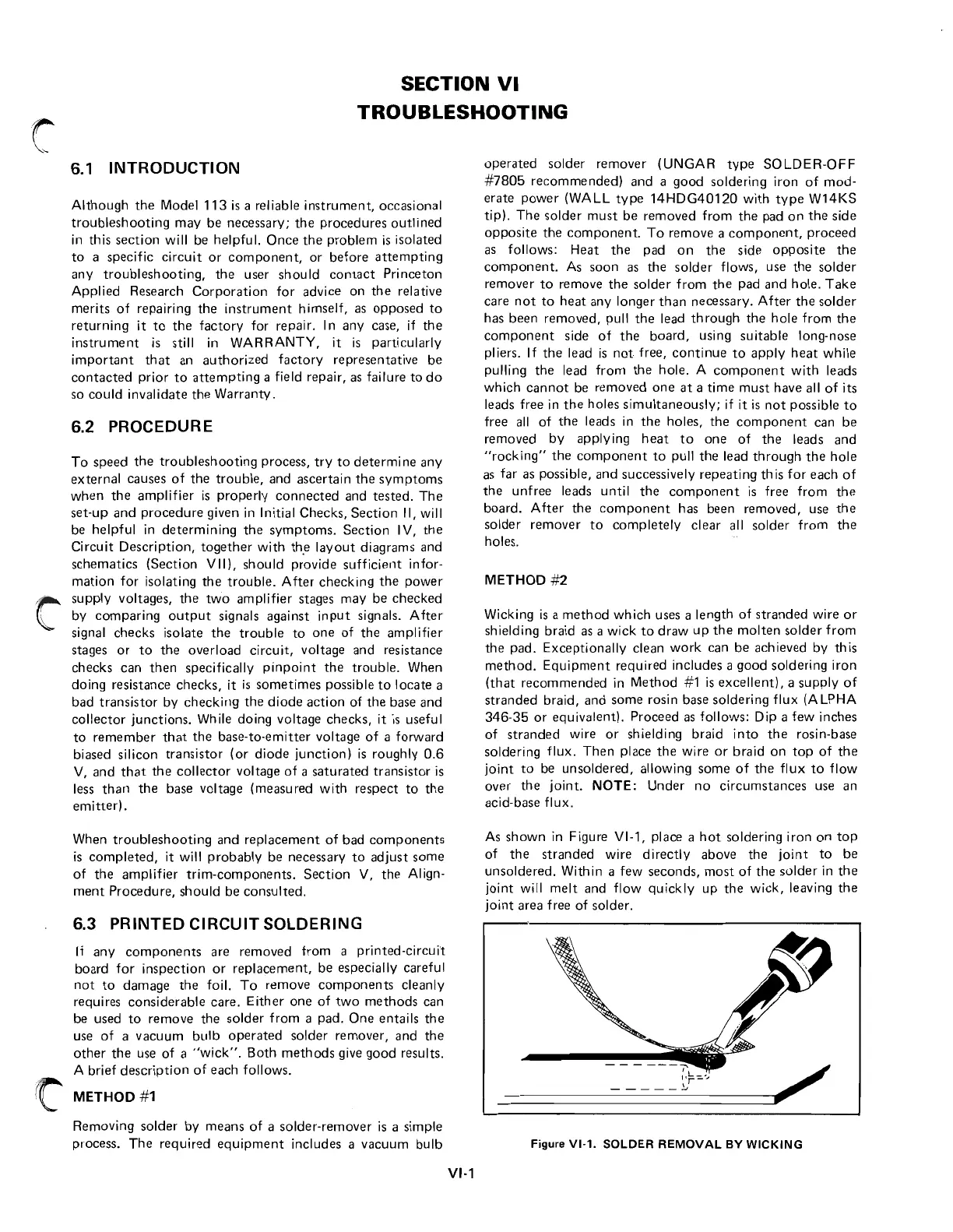

METHOD

#2

Wicking

is

a

method

which

uses a length

of

stranded

wire

or

shielding braid

as

a

wick

to

draw

up

the

molten

solder

from

the

pad.

Exceptionally

clean

work

can

be achieved by

this

method.

Equipment

required

includes a

good

soldering

iron

(that

recommended

in

Method

#1

is

excellent),

a

supply

of

stranded

braid,

and

some

rosin base

soldering

flux

(ALPHA

346-35

or

equivalent). Proceed

as

follows: Dip a few

inches

of

stranded

wire

or

shielding braid

into

the

rosin-base

soldering flux.

Then

place

the

wire

or

braid

on

top

of

the

joint

to

be

unsoldered,

allowing

some

of

the

flux

to

flow

over

the

joint.

NOTE:

Under

no

circumstances

use an

acid-base flux.

As

shown

in

Figure

VI-l,

place a

hot

soldering

iron

on

top

of

the

stranded

wire

directly

above

the

joint

to

be

unsoldered.

Within

a

few

seconds,

most

of

the

solder

in

the

joint

will

melt

and

flow

quickly

up

the

wick,

leaving

the

joi

nt

area free

of

solder.

-===================~/

Figure

VI-l.

SOLDER

REMOVAL

BY

WICKING

Loading...

Loading...