MAINTENANCE

20 NP-DK50 DE-18_02-2019

Checking tightness of joints and inspecting the equipment

Test for leakage:

Disconnect the outlet hose from the quick coupling OUT (3); compressed

air consumption will stop.

Pressurize the air tank by releasing some air via a connected device.

With the compressor off, wait at least 10 minutes before checking the

pressure level.

If the pressure has dropped, use soapy water to find the leaky joint. Start

with the joints outside the case, and then test the ones inside the case

after removing the covers.

Tighten or re-seal joints as necessary.

Inspect the equipment:

Check the status of the compressor motor for balanced operation or noise.

Check the condition of the hangers above the pump.

Check fan functionality.

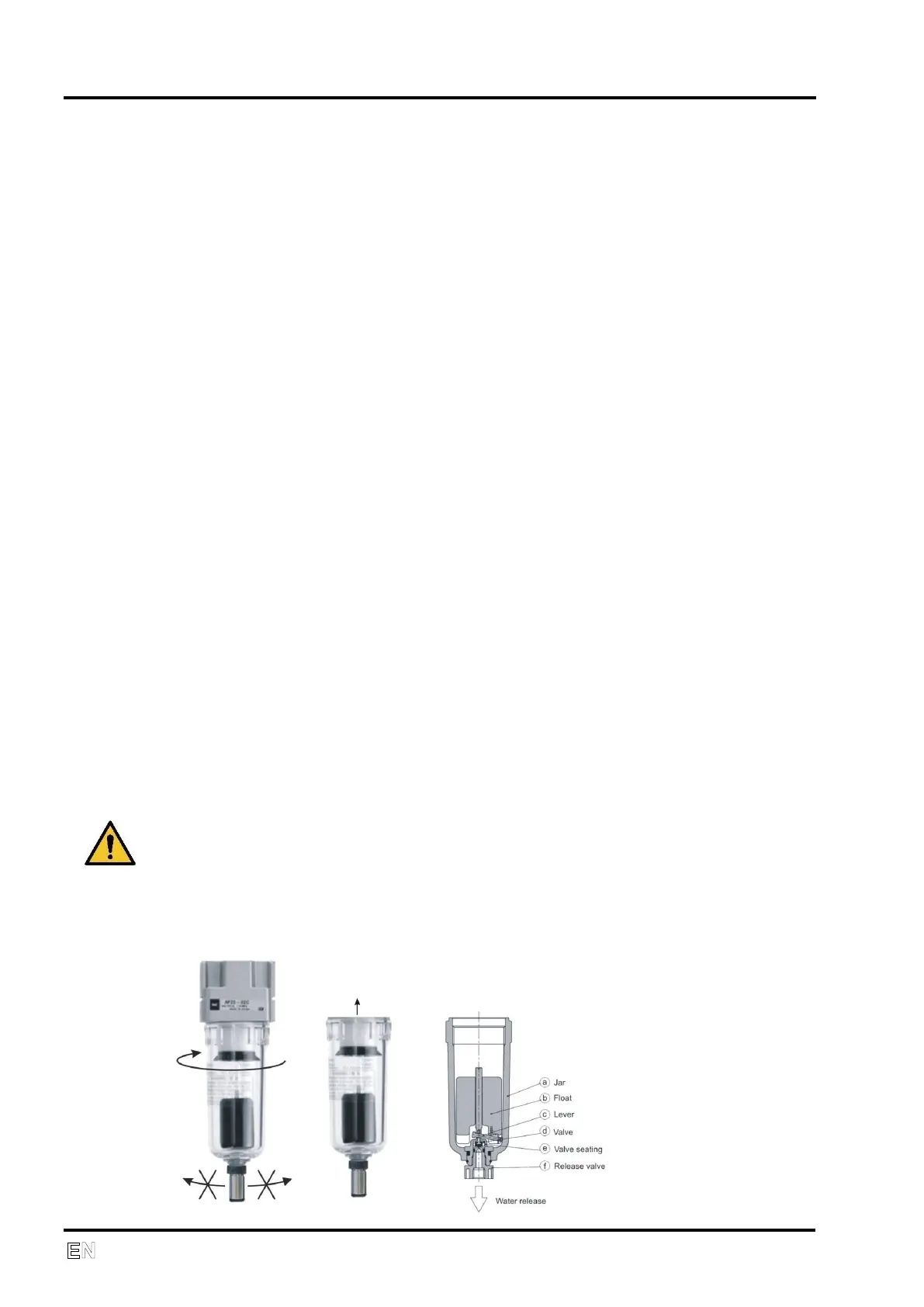

Check the condition of filters (14,16). With regular operation, condensate

drains automatically. Verify this function by comparing the level of

condensate in the tank to the scale line indicating the maximum level. If

the level of condensate is above the scale line, replace the faulty parts.

Examine the pump for:

- Defects in the crankcase

- Free movement of the crank shaft

If necessary, replace any faulty parts.

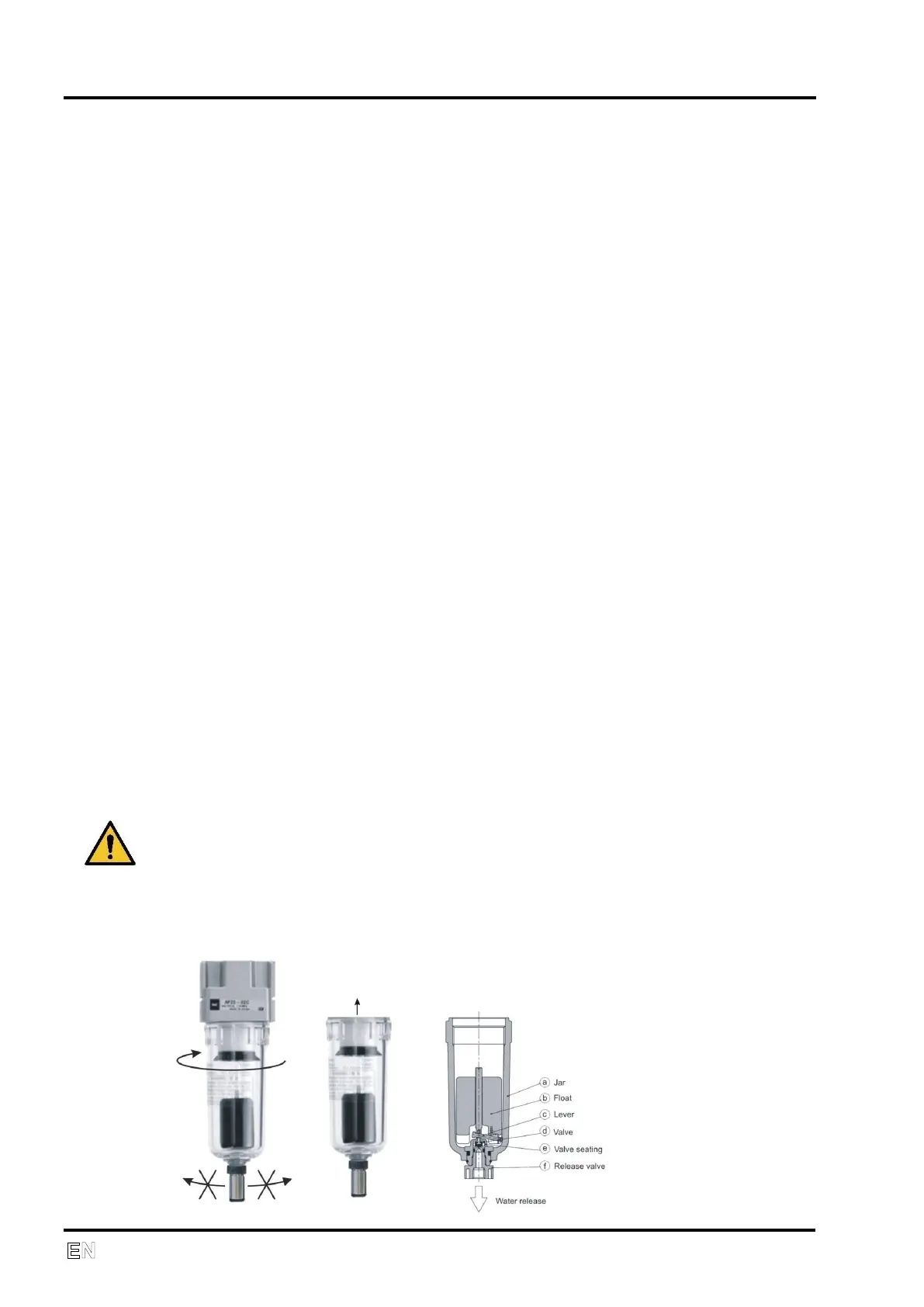

Replacing filter elements

Before beginning, evacuate all compressed air from the tank, reducing

the tank pressure to zero and disconnect the equipment from the power

mains.

Loading...

Loading...