25

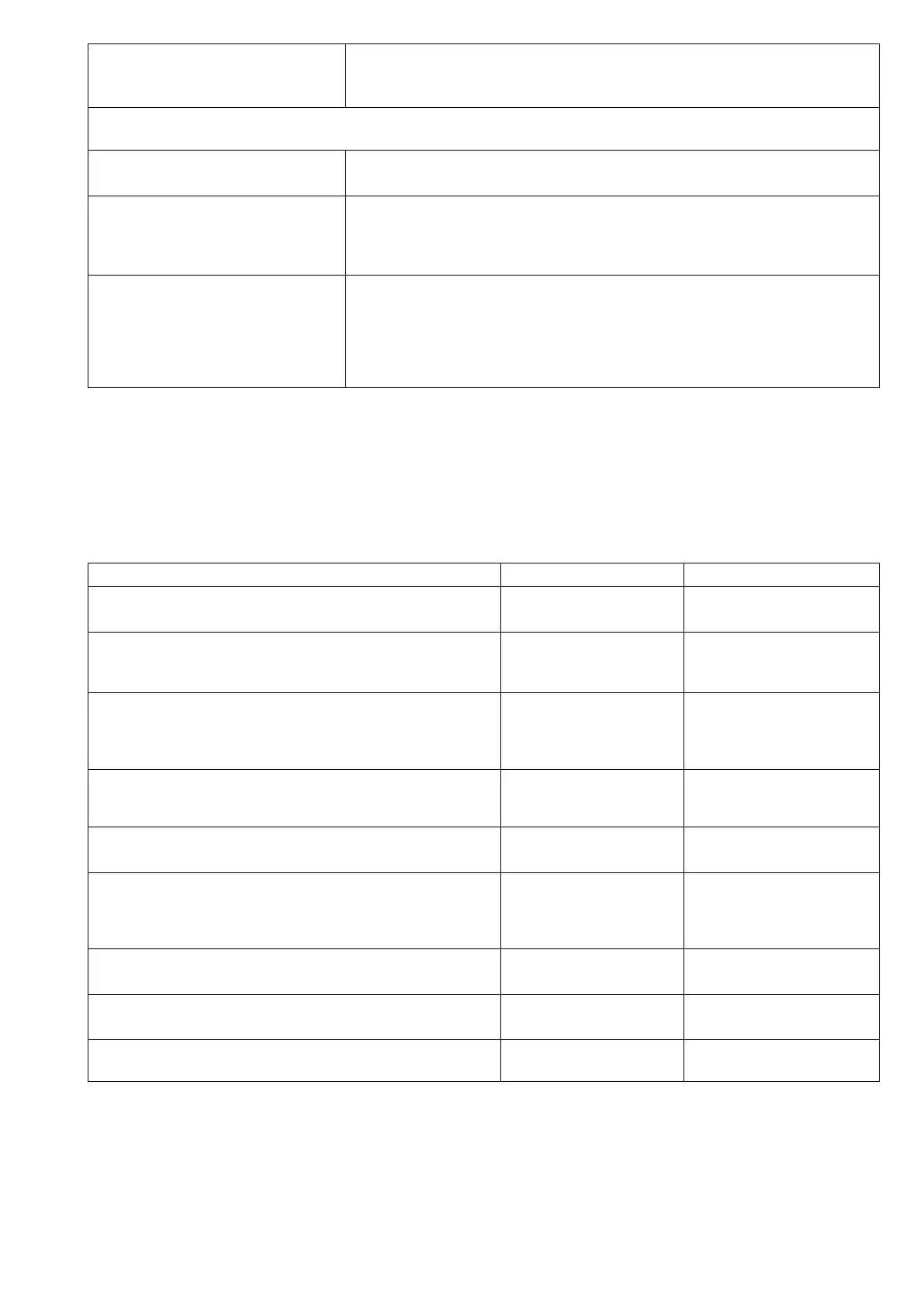

The main burner does not light

• Loss of pressure in gas pipe.

• Blocked nozzle or faulty gas valve.

• Burner with gas outlet holes clogged.

INSTRUCTIONS FOR REPLACING COMPONENTS (to be carried out only by specialised personnel)

Remove the front panel to access:

Gas valve

• Unscrew the pilot and thermocouple pipe, unscrew the gas inlet and outlet unions.

• For installation carry out the same procedure in reverse order.

Pilot burner, thermocouple, igniter

assembly

• To replace the igniter and thermocouple loosen the fixing screws and remove the

components.

• To replace the pilot burner undo the gas pipe, remove the pilot burner assembly.

• Replace the components, proceeding in reverse order to refit the parts.

Main burner

• Unscrew the gas connection from the nozzle holder.

• Undo the screws fixing the burner to the support.

• Remove the pilot burner assembly by undoing the screws.

• For installation carry out the same procedure in reverse order, making sure that

when positioning the burner the centring pins, located at the back of the burner,

enter their special seats.

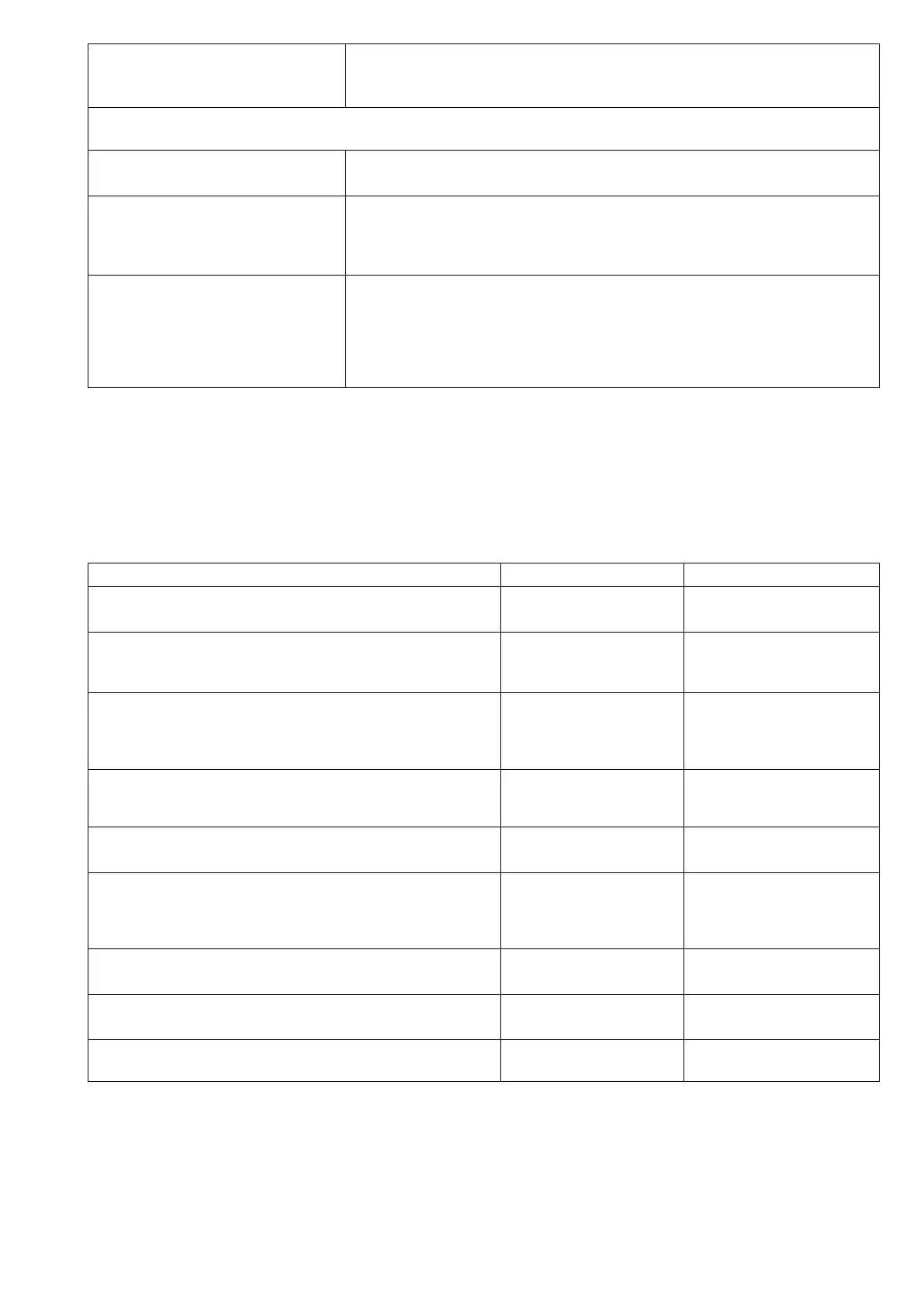

G.8 Maintenance and schedule

All the components requiring maintenance are accessible from the front or the rear panel of the appliance.

Maintenance frequency

• Machine maintenance, checking and overhaul operations must only be carried out by a specialised Technician or the Customer

Care Service, provided with adequate personal protection equipment (safety shoes and gloves), tools and ancillary means.

• Work on the electrical equipment must only be carried out by a specialised electrician or the Customer Care Service.

• To ensure constant machine efficiency, it is advisable to carry out the checks with the frequency given in the following table:

Maintenance, inspections, checks and cleaning Frequency Responsibility

Ordinary cleaning

• general cleaning of machine and surrounding area.

Daily Operator

Mechanical protection devices

• check their condition and for any deformation, loosening or

removed parts.

Yearly Service

• Control

check the mechanical part, for cracks or deformation, tighten-

ing of screws: check the readability and condition of words,

stickers and symbols and restore if necessary.

Yearly Service

Machine structure

• tightening of main bolts (screws, fixing systems, etc.) of

machine.

Yearly Service

• Safety signs

check the readability and condition of safety signs.

Yearly Service

• Electrical control panel

check the electrical components installed inside the electrical

control panel. Check the wiring between the electrical panel

and machine parts.

Yearly Service

• Electrical connection cable and plug

check the connection cable (replace if necessary) and plug.

Yearly Service

• Extraordinary machine maintenance

check all gas components (if present).

Yearly Service

General machine overhaul

• check all components, electrical equipment, corrosion, pipes…

Every 10 years

1

Service

1. the machine is designed and built for a duration of about 10 years. After this period of time (from commissioning) the machine must undergo a general

inspection and overhaul. Some examples of checks to be carried out are given below.

• Check for any oxidised electrical components or parts; if necessary, replace them and restore the initial conditions;

• Check the structure and welded joints in particular;

• Check and replace bolts and/or screws, also checking for any loose components;

• Check the electrical and electronic system;

• Check the functionality of safety devices;

• Check the general condition of protection devices and guards.

Loading...

Loading...