Checking the crimp result

To make sure the tool has made the required deformation for the specifi c cable connector, securing mechanical

strength and fi rst-rate electrical contact properties, the crimp should be inspected.

For Cu-terminals and -connectors, the following applies:

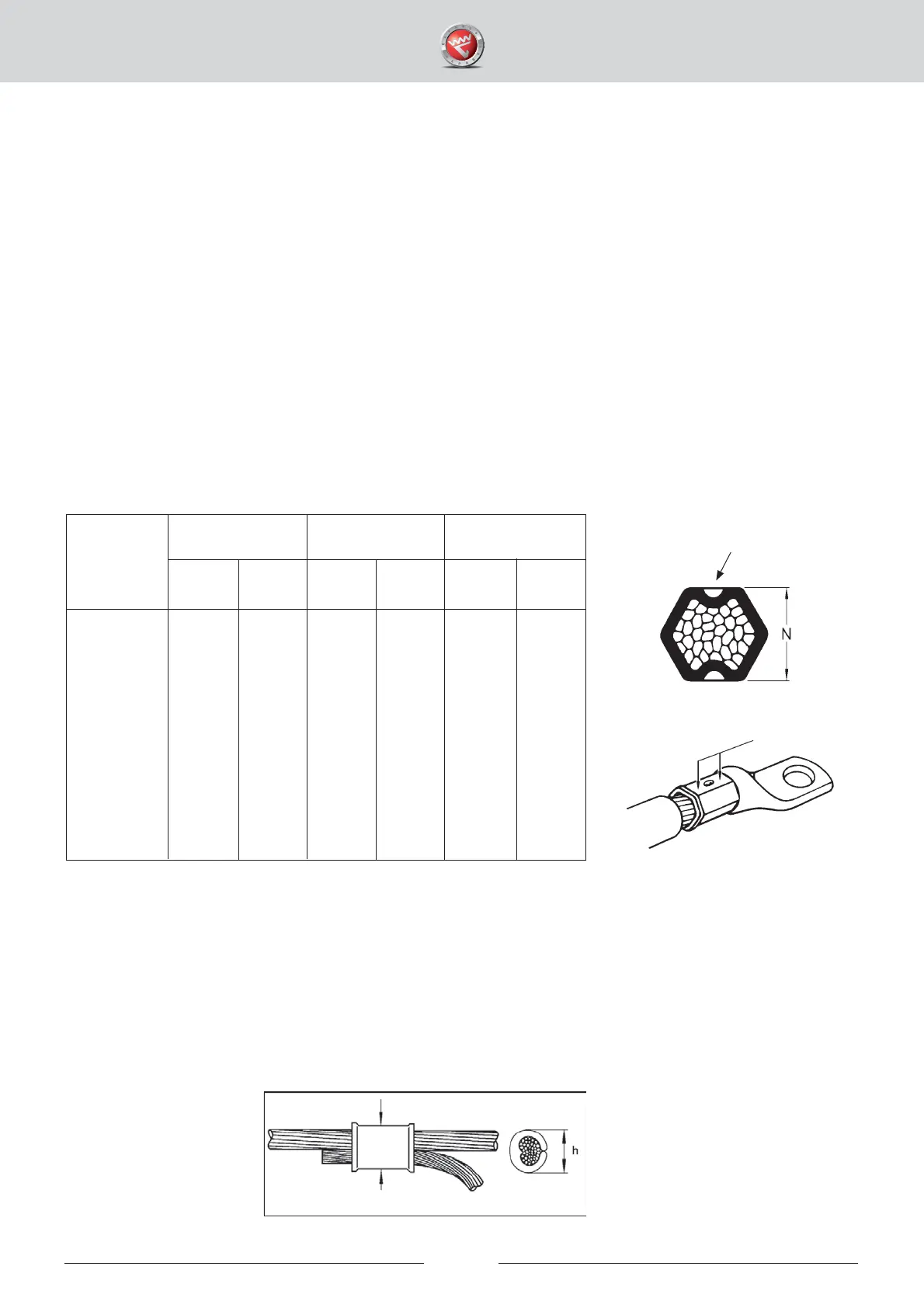

• The check of the gauge measure N is to be made on the hexagon sides that have pattern

stampings from the press dies.

• Check with a slide calliper on one or both sides of the stamp and compare with the N-gauge

measure in the table below.

• Should the test result exceed the N-gauge measure in the table below after properly performed

crimping, contact nearest authorized Elpress Service shop.

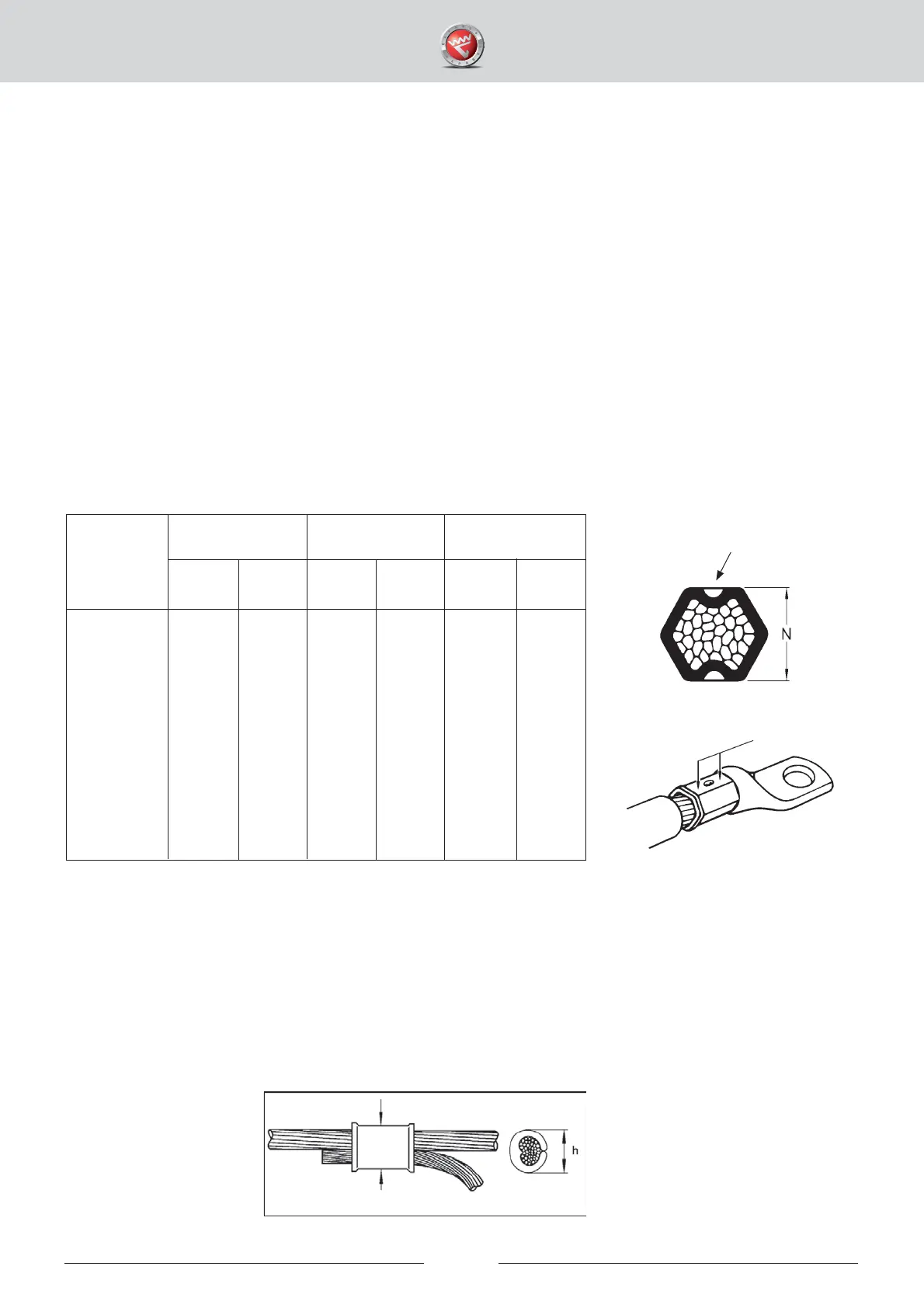

C-sleeves from Cu should be checked with regard to the size ”h”. The ”h”-size is best measured with a slide

calliper on the maximum height of the crimped oval. The measurement should be compared with those in the

table on the next page.

Should the ”h”-size be exceeded following a properly performed crimping operation, contact nearest authorized

Elpress Service shop.

IMPORTANT! When processing C-sleeves, there must always be conductor strands outside the outer

edges of the C-sleeve. The minimum length of the strands sticking out must correspond to

at least 60 % of the diameter of the conductor.

16

Cu-

conductor

mm

2

KRF/KSF types KRD/KSD types KRT/KST types

Press-

die no

Press-

die no

Press-

die no

Max N

mm

Max N

mm

Max N

mm

10

16

25

35

50

70

95

120

150

185

240

300

400

8

9

11

13

14,5

17

20

22

25

27

30

32

38

6,3

7,3

8,8

10,2

11,4

13,4

16,4

16,3

20,3

20,5

23,3

24,5

30,5

-

8

9

11

12

14

16

19

22

25

27

30

32

-

6,3

7,3

8,8

10,2

11,6

13,2

15,4

16,3

20,3

20,5

23,3

24,5

7

8,5

10

12

14

16

18

19

22

24

26

30

32

5,9

7,5

8,2

10,2

11,6

13,2

14,0

15,4

16,3

17,7

19,5

23,3

24,5

Measuring

points

Pattern stamp

Measuring points

Loading...

Loading...