5

Application Engineering

BULLETIN

AE4-1383 R5

© 2012 Emerson Climate Technologies, Inc.

Printed in the U.S.A.

ZF*K5E Low Temperature K5 Compressors for

Refrigeration

The low temperature models are provided with an

injection port that can be used for either liquid or vapor

injection.

Liquid Injection

When using the ZF*K5E scrolls for liquid injection

operation, a discharge temperature control (DTC)

valve must be applied. The purpose of the DTC valve

is to eliminate the need for a standard capillary tube.

The DTC valve is approved for all refrigerants in

this product range. A DTC valve must also be used

for ZF**K5E applications with R-407A, R-407C and

R-407F (R-407A/C/F) with vapor injection via a special

T-fi tting adapter. Further details and part numbers

related to the DTC valve are listed in Table 1 at the

end of this bulletin.

DTC Valve Specifications

The following components are not required, but they

are recommended for liquid injection.

• Sight Glass - A sight glass can be installed before

the DTC valve to allow for visual inspection for the

presence of liquid refrigerant.

• Filter/Drier - A filter/drier should be installed

upstream of the injection circuit to avoid the

possibility of the DTC screen blockage due to

contaminants.

Figures 2A through 2C are a representation of typical

systems, depicting the location of these components

Installation of DTC Valve

The valve bulb must be installed in the top cap thermal

well to adequately control scroll temperatures. The

valve should be tightened on the injection fitting to

a torque of 216-245 in. lbs. (24.4 - 27.7 Nm). A 90°

orientation on the valve is recommended, however it will

function properly in any orientation. The capillary tube

connecting the valve to the bulb should be positioned

such that it does not contact the compressor during

operation. Do not bend the capillary tube within 1”

(25.4mm) of the valve.

The DTC valve comes with an insulating cap. If this

additional height from the cap is an issue, the valve

cap could be replaced with high temperature insulation.

This should be applied to insulate and protect the valves

remote bulb assembly. This will reduce the total height

requirement by 0.5” (12.7mm).

Suggested Application Techniques for the DTC

Valve

For the most efficient thermal sensing, spread a thin film

of thermal grease around the DTC valve bulb before

installing into the top cap well. However for proper

functioning of the valve this is not required.

• For service purposes, a mechanical ball valve (not

provided by Emerson) is also recommended in the

liquid and vapor injection line.

For the liquid injection system to be effective, a

minmum of 5°F subcooled liquid at the at the DTC inlet

is required.

Note! To ensure adequate temperature control,

take care to not damage the DTC valve bulb when

installing.

Vapor Injection

The ZF*K5E 8-15 HP scrolls can also be applied with

vapor injection by implementing an economizer circuit

in the system. Economizing is accomplished by utilizing

a subcooling circuit similar to that shown in Figure 3 at

the end of this bulletin. This mode of operation increases

the refrigeration capacity and in turn the efficiency of

the system.

The schematic shows a system configuration for

the economizer cycle. A heat exchanger is used to

provide subcooling to the refrigerant before it enters

the evaporator. This subcooling process provides the

increased capacity gain for the system, as described

above. During the subcooling process a small amount

of refrigerant is evaporated and superheated. This

superheated refrigerant is then injected into the mid

compression cycle of the scroll compressor and

compressed to discharge pressure. This injected vapor

also provides cooling at higher compression ratios, similar

to liquid injection of standard ZF scroll compressors. The

benefits provided will increase as the compression ratio

increases, thus, more gains will be made in summer

when increased capacity may actually be required.

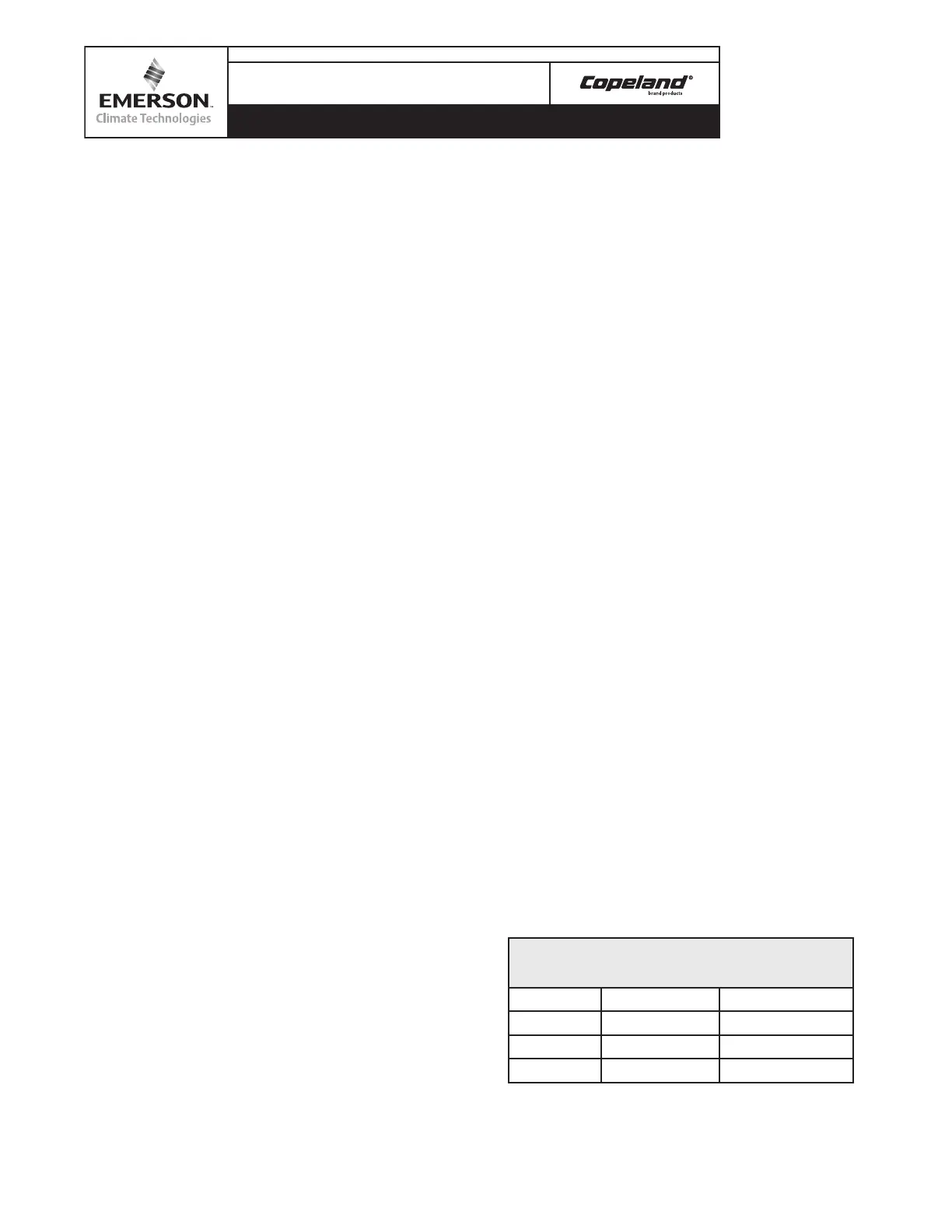

An example of the additional capacity available when

using vapor injection is depicted in the following table.

ARI Low Temperature Ratings

(-25°F/105°F, R-404A)

Model With EVI* Without EVI*

ZF34K5E 48,100 Btu/hr 34,200 Btu/hr

ZF41K5E 57,500 Btu/hr 42,200 Btu/hr

ZF49K5E 71,000 Btu/hr 50,500 Btu/hr

*

Maximum possible subcooling

* Without EVI is “0” subcooling

Loading...

Loading...