DVC6000 Digital Valve Controllers

September 2013

2-32

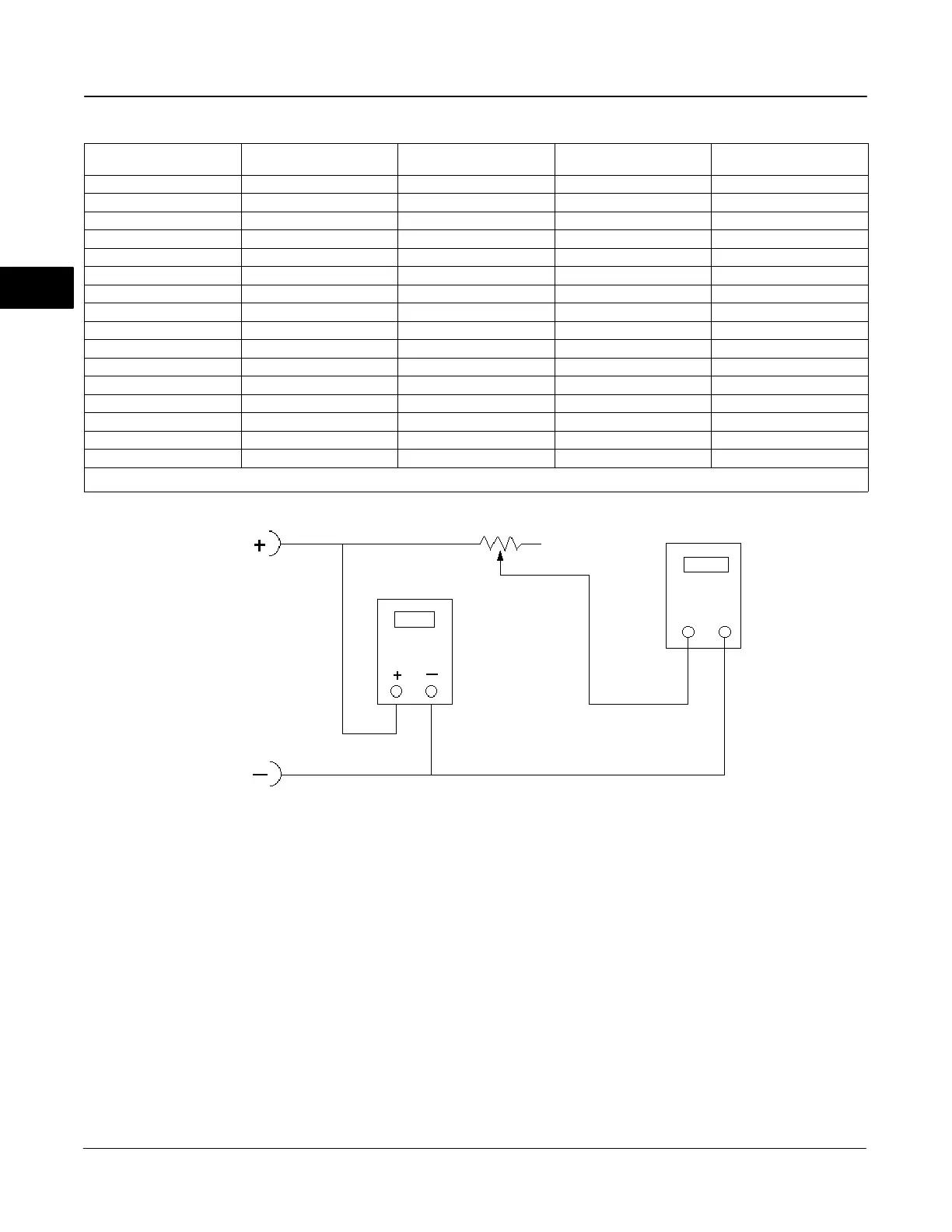

Table 2-1. Cable Characteristics

Cable Type

Capacitance

(1)

pF/Ft

Capacitance

(1)

pF/m

Resistance

(2)

Ohms/ft

Resistance

(2)

Ohms/m

BS5308/1, 0.5 sq mm 61.0 200 0.022 0.074

BS5308/1, 1.0 sq mm 61.0 200 0.012 0.037

BS5308/1, 1.5 sq mm 61.0 200 0.008 0.025

BS5308/2, 0.5 sq mm 121.9 400 0.022 0.074

BS5308/2, 0.75 sq mm 121.9 400 0.016 0.053

BS5308/2, 1.5 sq mm 121.9 400 0.008 0.025

BELDEN 8303, 22 awg 63.0 206.7 0.030 0.098

BELDEN 8441, 22 awg 83.2 273 0.030 0.098

BELDEN 8767, 22 awg 76.8 252 0.030 0.098

BELDEN 8777, 22 awg 54.9 180 0.030 0.098

BELDEN 9501, 24 awg 50.0 164 0.048 0.157

BELDEN 9680, 24 awg 27.5 90.2 0.048 0.157

BELDEN 9729, 24 awg 22.1 72.5 0.048 0.157

BELDEN 9773, 18 awg 54.9 180 0.012 0.042

BELDEN 9829, 24 awg 27.1 88.9 0.048 0.157

BELDEN 9873, 20 awg 54.9 180 0.020 0.069

1. The capacitance values represent capacitance from one conductor to all other conductors and shield. This is the appropriate value to use in the cable length calculations.

2. The resistance values include both wires of the twisted pair.

CIRCUIT

UNDER

TEST

VOLTMETER

MILLIAMMETER

1 kW POTENTIOMETER

A6192-1/IL

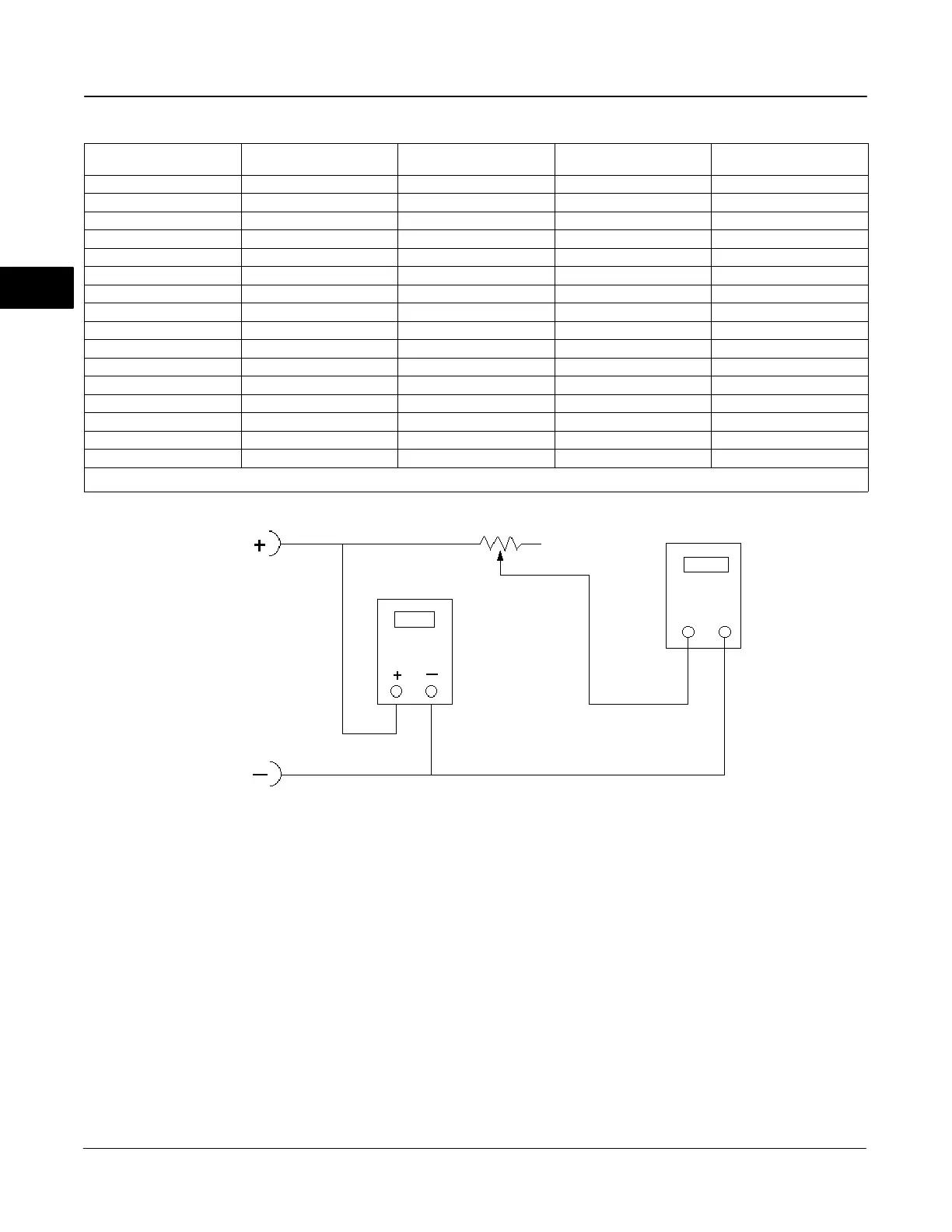

Figure 2-26. Voltage Test Schematic

Compliance Voltage

If the compliance voltage of the control system is not

known, perform the following compliance voltage test.

1. Disconnect the field wiring from the control system

and connect equipment as shown in figure 2-26 to the

control system terminals.

2. Set the control system to provide maximum output

current.

3. Increase the resistance of the 1 kW potentiometer,

shown in figure 2-26, until the current observed on the

milliammeter begins to drop quickly.

4. Record the voltage shown on the voltmeter. This is

the control system compliance voltage.

For specific parameter information relating to your

control system, contact your Emerson Process

Management sales office.

2

Loading...

Loading...