DVC6000f Digital Valve Controllers

December 2009

4-152

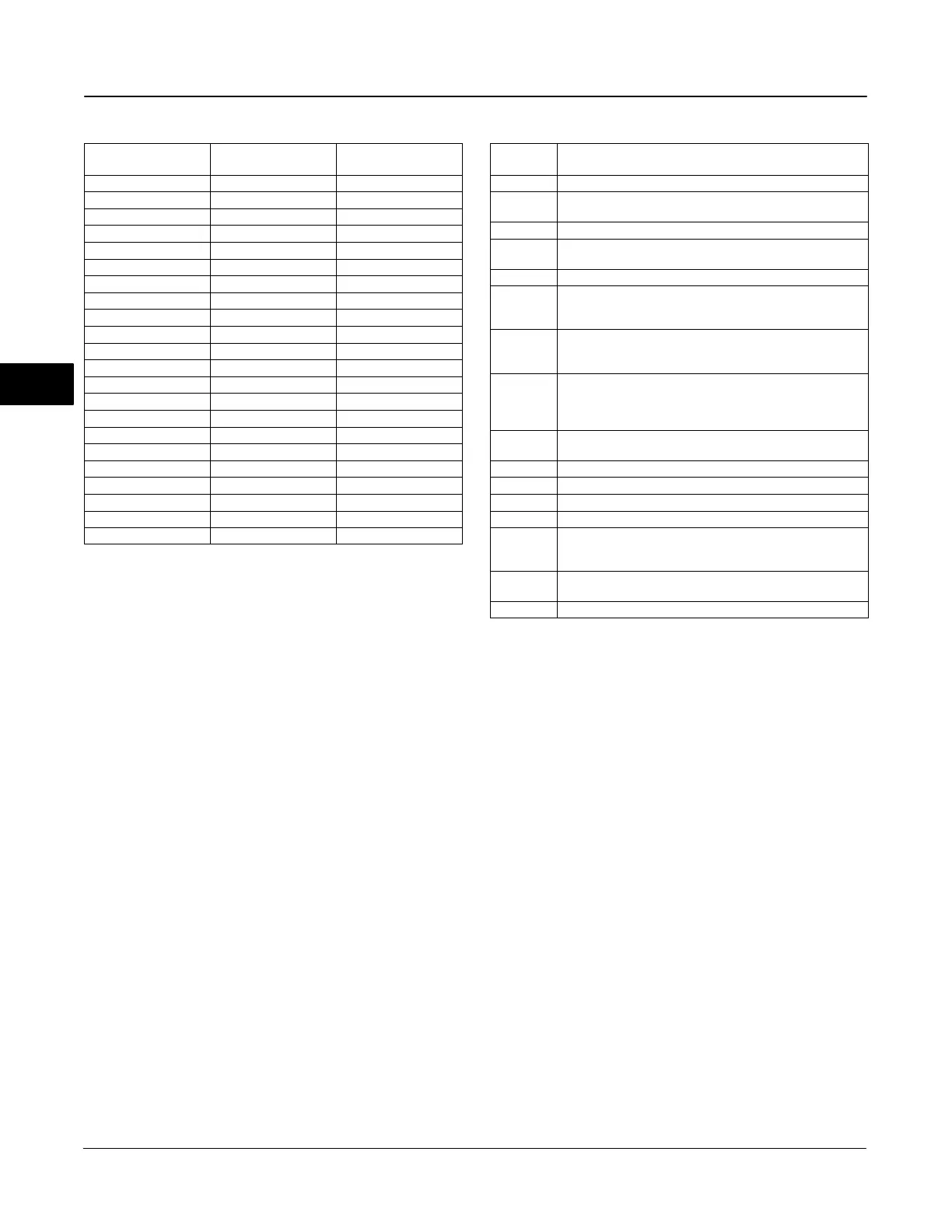

Table 4-69. Valve Set Point for Discrete State

Discrete State

Valve Set Point with

IO_OPTS Invert = 0

Valve Set Point with

IO_OPTS Invert = 1

0 Closed Open

1 Open Closed

5 5% Closed

10 10% Closed

15 15% Closed

20 20% Closed

25 25% Closed

30 30% Closed

35 35% Closed

40 40% Closed

45 45% Closed

50 50% Closed

55 55% Closed

60 60% Closed

65 65% Closed

70 70% Closed

75 75% Closed

80 80% Closed

85 85% Closed

90 90% Closed

95 95% Closed

100 Open Closed

(PV_D [7]), and a manually-entered SP_D [8] value is

overwritten on the block’s next execution cycle. This

option can prevent a state change when transitioning

from Manual to Automatic mode. You can disable this

option in Manual or Out of Service mode only.

The Invert option inverts the set point at SP_D [8]

before it is stored in OUT_D [9]. With this option

enabled, OUT_D [9] becomes an inverted copy of

SP_D [8] where non-zero values of SP_D [8] are

considered a logic 1. With this option disabled, OUT_D

[9] is a direct copy of SP_D [8]. The readback value is

processed through the Invert option to become PV_D

[7]. The Use PV for BKCAL_OUT option specifies that

BKCAL _OUT equal the value of the process variable

(PV_D [7]) instead of the set point (SP_D [8]). If you

do not enable this option, BKCAL_OUT will equal

SP_D [8].

Output Block PV Status

The Output Block PV Status is determined by the

value of the PlantWeb Alerts Set PV Status parameter

in the transducer block (PWA_SET_STATUS [97]),

the Transducer Block mode, and enabled Active

PlantWeb alarms. Refer to table 4-10.

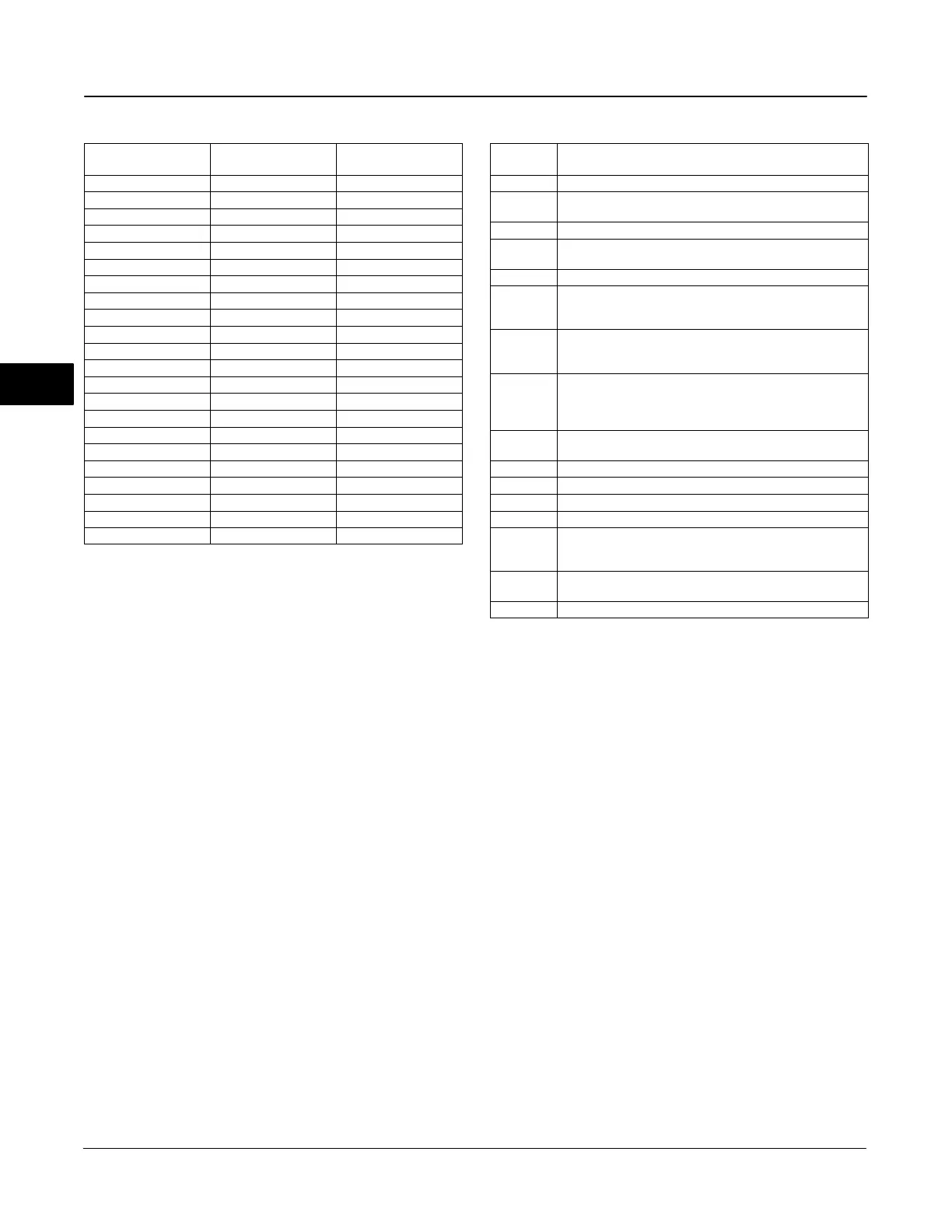

Table 4-70. BLOCK_ERR Conditions

Condition

Number

Condition Name and Description

0 Other (N/A)

1

Block Configuration Error - SHED_OPT or CHANNEL set to

0 (uninitialized)

2 Link Configuration Error (N/A)

3

Simulate active - Simulation is enabled and the block is using

a simulated value in its execution.

4 Local Override - Device in fault state. Actual mode LO.

5

Device Fault State Set - DO block in fault state after

FSTATE_TIME because of Bad status or IFS substatus on

CAS_IN_D or Resource block commanded fault state.

6

Device Needs Maintenance Soon - Indicates a Maintenance

PlantWeb Alert condition is active if Block Error Reporting is

enabled. See page 4-40.

7

Input failure/process variable has Bad status - PV has bad

status and Feature Select in the Resource block has the Out

Readback bit set or the transducer block mode is Out of

Service.

8

Output failure - PV has bad status or the transducer block

mode is Out of Service.

9 Memory Failure (N/A)

10 Lost Static Data (N/A)

11 Lost NV Data (N/A)

12 Readback Check Failed (N/A)

13

Device Needs Maintenance Now - Indicates Failed

PlantWeb Alert condition is active if Block Error Reporting is

enabled. See page 4-40.

14

Power Up - This condition exists after power up until actual

mode is not Out of Service.

15 Out of Service - The block is in Out of Service (OOS) mode.

Block Errors

Table 4-70 lists conditions reported in the

BLOCK_ERR [6] parameter. Conditions in italics are

not applicable for the DO block and are provided only

for your reference.

Action on Fault Detection

Fault State is caused by one of three sources: A

status pertaining to CAS, A status pertaining to RCAS,

or SET_FSTATE [29] in the resource block. To

implement Fault State, configure the following

parameters:

IO_OPTS [14]: Determines the action OUT_D [9] will

take upon a fault state. If the IO_OPTS [14] “Fault

State to Value” is not selected, then OUT_D [9] holds

its last position when Fault State is set. If “Fault State

to Value” is selected, OUT_D [9] goes to the

FSTATE_VAL_D [20] value when Fault State is set.

FSTATE_TIME [19]: The length of time, in seconds,

that the DO block will wait to set Fault State. When

4

Loading...

Loading...