Maintenance and Troubleshooting

December 2009

7-5

Table 7-1. Tools Required

Tool Size Use

Phillips Screwdriver

Hex key

Hex key

Hex key

Hex key

5 mm

1.5 mm

2.5 mm

5 mm

Relay, printed wiring board

assembly, and cover screws

Terminal box screw

Terminal box cover screw

I/P converter screws

Travel sensor screws

Hex key

Open-end wrench

Hex key

Open-end wrench

Hex key

6 mm

1/2-inch

9/64-inch

7/16-inch

3/16-inch

Module base screws

Connector Arm screw (DVC6010f)

Feedback arm screw

DVC6010f mounting bolts

DVC6020f mounting bolts

2. Unscrew the four captive screws in the cover

(key 43) and remove the cover from the module base

(key 2).

3. Using a 6 mm hex socket wrench, loosen the

three-socket head screws (key 38). These screws

are captive in the module base by retaining rings

(key 154).

Note

The module base is linked to the

housing by two cable

assemblies. Disconnect these

cable assemblies after you pull

the module base out of the

housing.

CAUTION

To avoid affecting performance of the

instrument, take care not to damage

the module base seal or guide surface.

Do not bump or damage the bare

connector pins on the PWB assembly.

Damaging either the module base or

guide surface may result in material

damage, which could compromise the

instruments ability to maintain a

pressure seal.

4. Pull the module base straight out of the housing

(key 1). Once clear of the housing, swing the module

base to the side of the housing to gain access to the

cable assemblies.

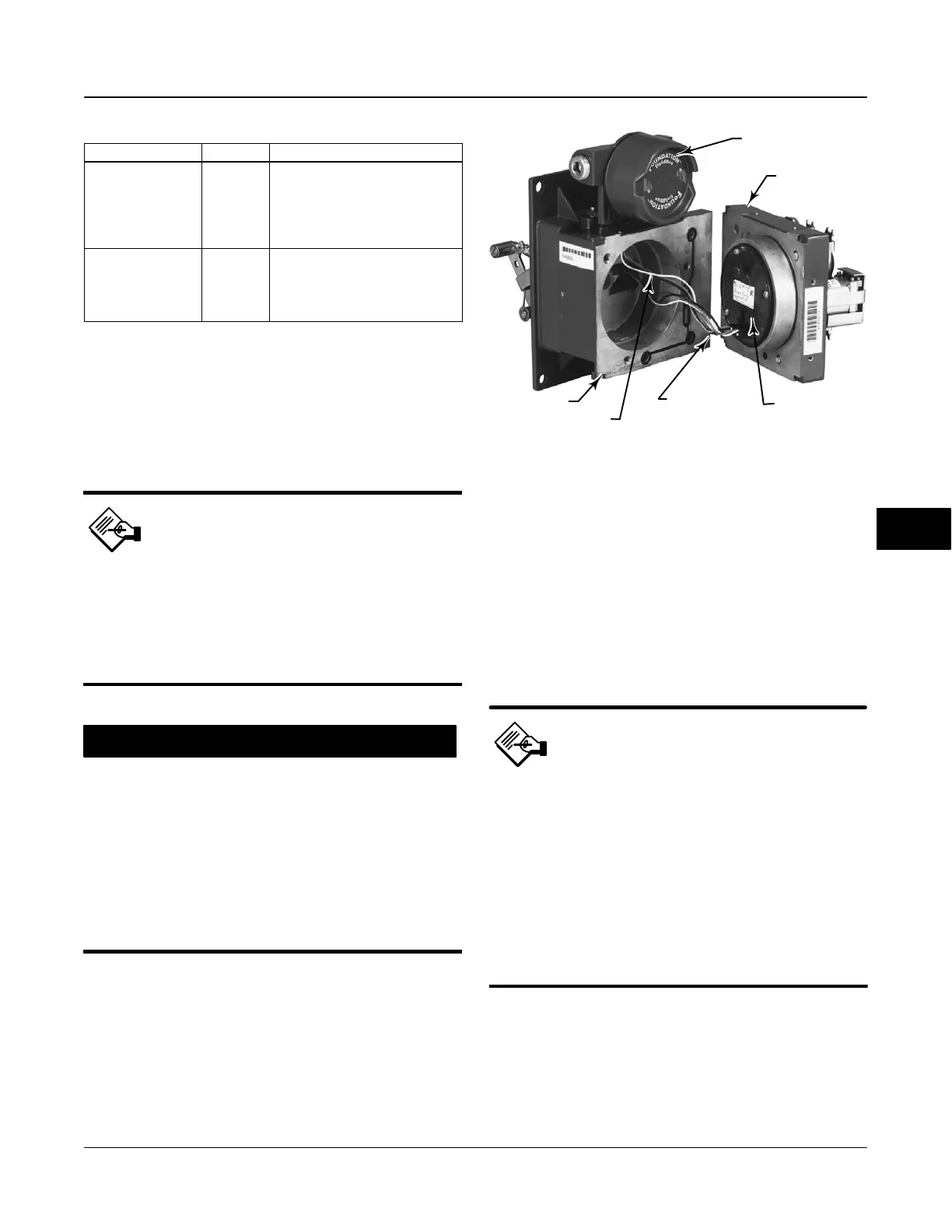

5. The digital valve controller has two cable

assemblies, shown in figure 7-1, which connect the

module base, via the printed wiring board assembly, to

the travel sensor and the terminal box. Disconnect

Figure 7-1. Printed Wiring Board Cable Connections

TERMINAL BOX

MODULE BASE

ASSEMBLY

PRINTED WIRING

BOARD ASSEMBLY

HOUSING

CABLE TO

TERMINAL BOX

W8073-FF

CABLE TO

TRAVEL SENSOR

these cable assemblies from the printed wiring board

assembly on the back of the module base.

Replacing the Module Base

To replace the module base, for DVC6010f, DVC6020f

and DVC6030f digital valve controllers, perform the

following steps. Refer to figures 8-2, 8-3, and 8-4,

respectively, for key number locations. Refer to figure

7-2 for a view of the back of the PWB assembly

sub-module.

Note

Inspect the guide surface on the

module and the corresponding seating

area in the housing before installing

the module base assembly. To avoid

affecting performance of the

instrument, these surfaces must be

free of dust, dirt, scratches, and

contamination.

Ensure the module base seal is in

good condition. Do not reuse a

damaged or worn seal.

1. Ensure the module base seal (key 237) is properly

installed in the housing (key 1). Ensure the O-ring (key

12) is in place on the module base assembly.

2. Connect the terminal box connector to the PWB

assembly (key 50). Orientation of the connector is

required.

7

Loading...

Loading...