• If the purge gas is heavier than air (such as argon), locate the inlet lower than the

outlet, so that the purge gas will displace air from bottom to top.

• If the purge gas is lighter than air (such as nitrogen), locate the inlet higher than

the outlet, so that the purge gas will displace air from top to bottom.

5. Make sure that there is a tight seal between the inlet connection and sensor case, so

that air cannot be drawn by suction into the case or purge line during the purging

process.

6. Run purge gas through the sensor.

The purge time is the amount of time required for full exchange of atmosphere to

inert gas. The larger the line size, the greater amount of time is required to purge

the case. If purge lines are being used, increase the purge time to fill the additional

volume of the purge line.

Important

Keep the purge gas pressure below 7.25 psi (0.5 bar).

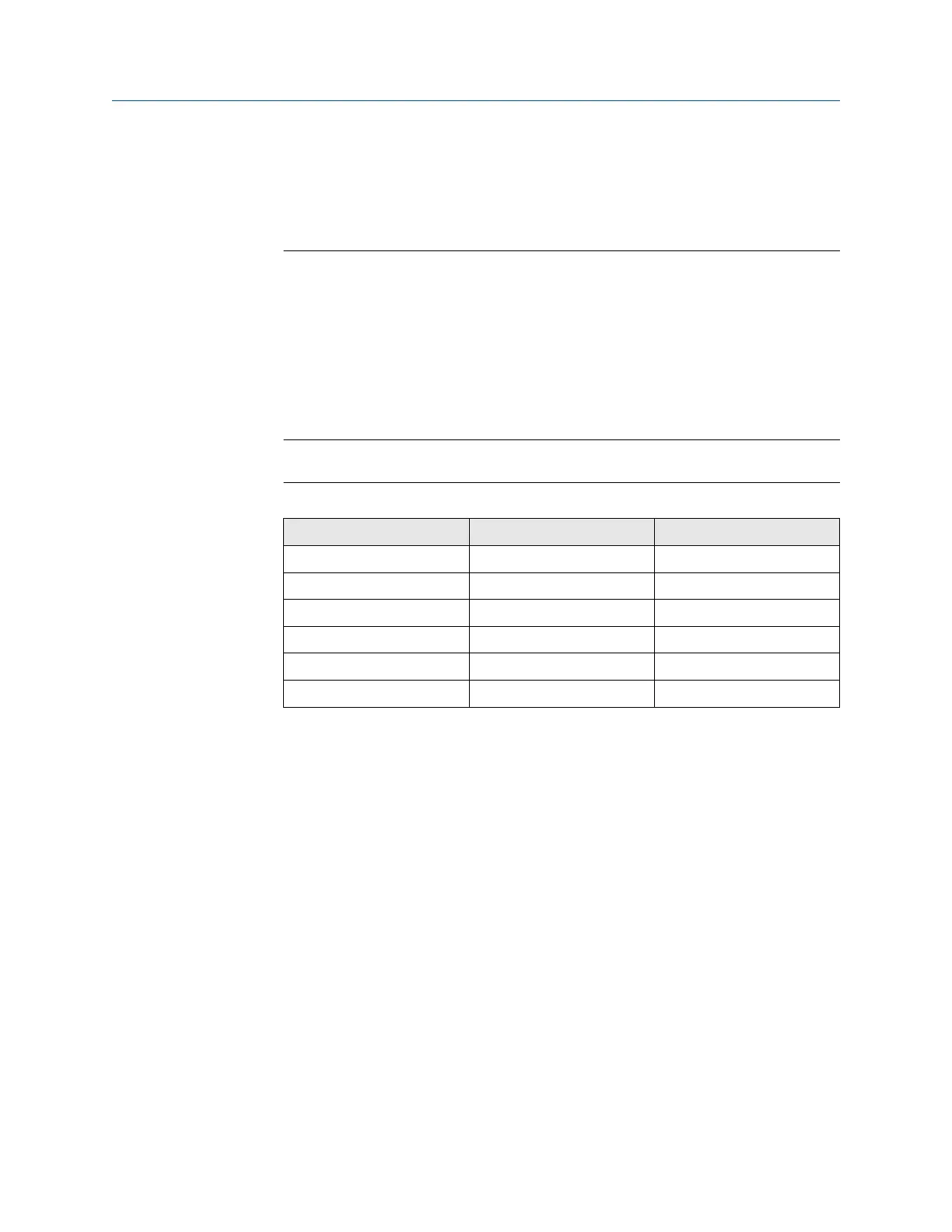

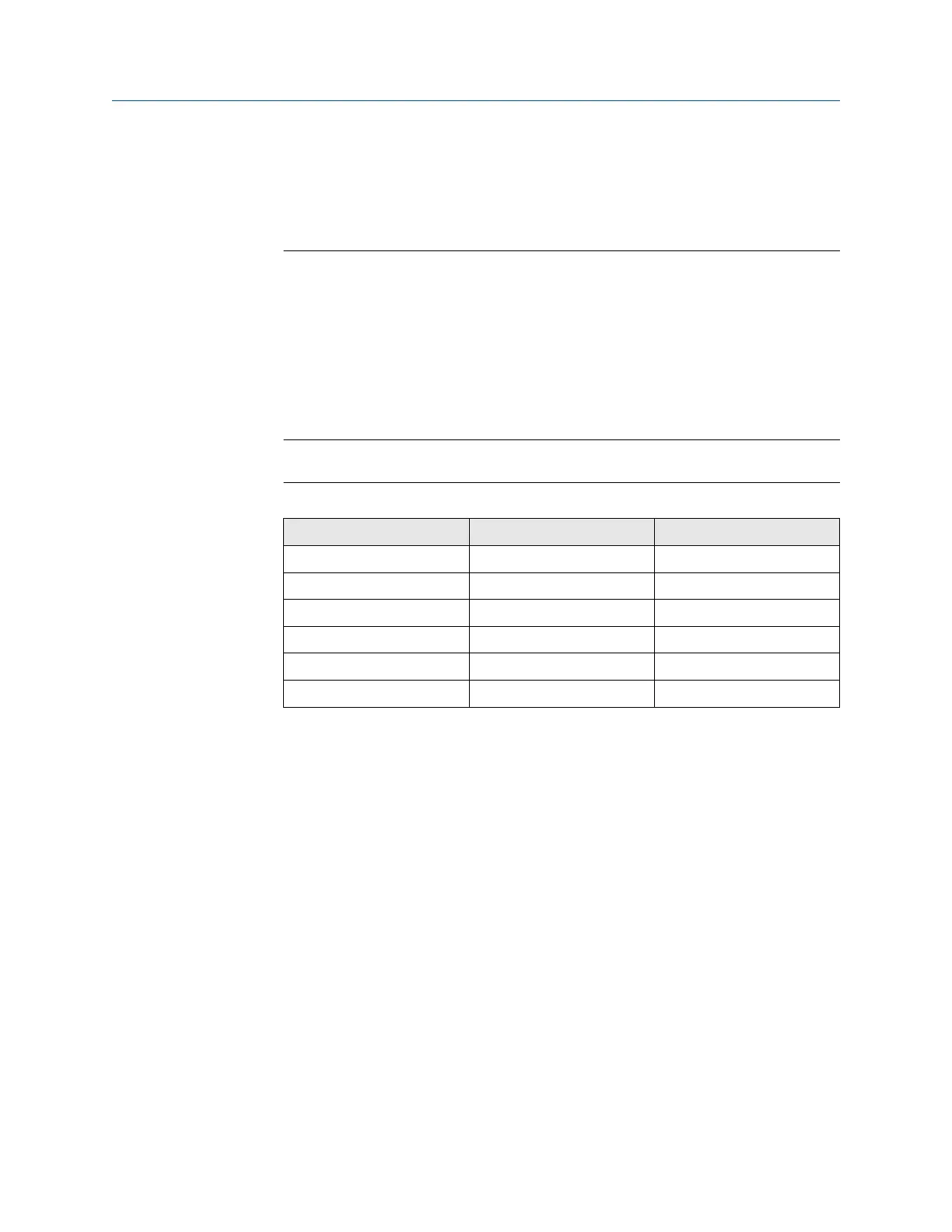

Table 6-1: Purge time

Sensor model Purge rate Time, in minutes

F025 20 ft3/h (566.3 l/h) 4 1/2

F050 20 ft3/h (566.3 l/h) 4 1/2

F100 20 ft3/h (566.3 l/h) 6

F200 20 ft3/h (566.3 l/h) 15

F300 20 ft3/h (566.3 l/h) 25

F400 20 ft3/h (566.3 l/h) 25

7. At the appropriate time, shut off the gas supply, then immediately seal the purge

outlet and inlet connections with the purge plugs.

Avoid pressurizing the sensor case. If pressure inside the case elevates above

atmospheric pressure during operation, the flowmeter density calibration will be

inaccurate.

8. Make sure that the purge fitting seals are tight so that air cannot be drawn by

suction into the sensor case.

6.2 Pressure relief

F-Series sensors are available with a rupture disk installed on the case. Exceptions are high-

temperature models (base model codes A and B) that are not available with rupture disks.

Rupture disks vent process fluid from the sensor case in the unlikely event of a flow tube

breach. Some users connect a pipeline to the rupture disk to help contain escaping

process fluid. For more information about rupture disks, contact customer service.

If the sensor has a rupture disk, keep it installed at all times as it would otherwise be

necessary to re-purge the case. If the rupture disk is activated by a tube breach, the seal in

the rupture disk will be broken, and the Coriolis meter should be removed from service.

Supplementary information Installation Manual

April 2020 20002298

22 Micro Motion F-Series

Loading...

Loading...