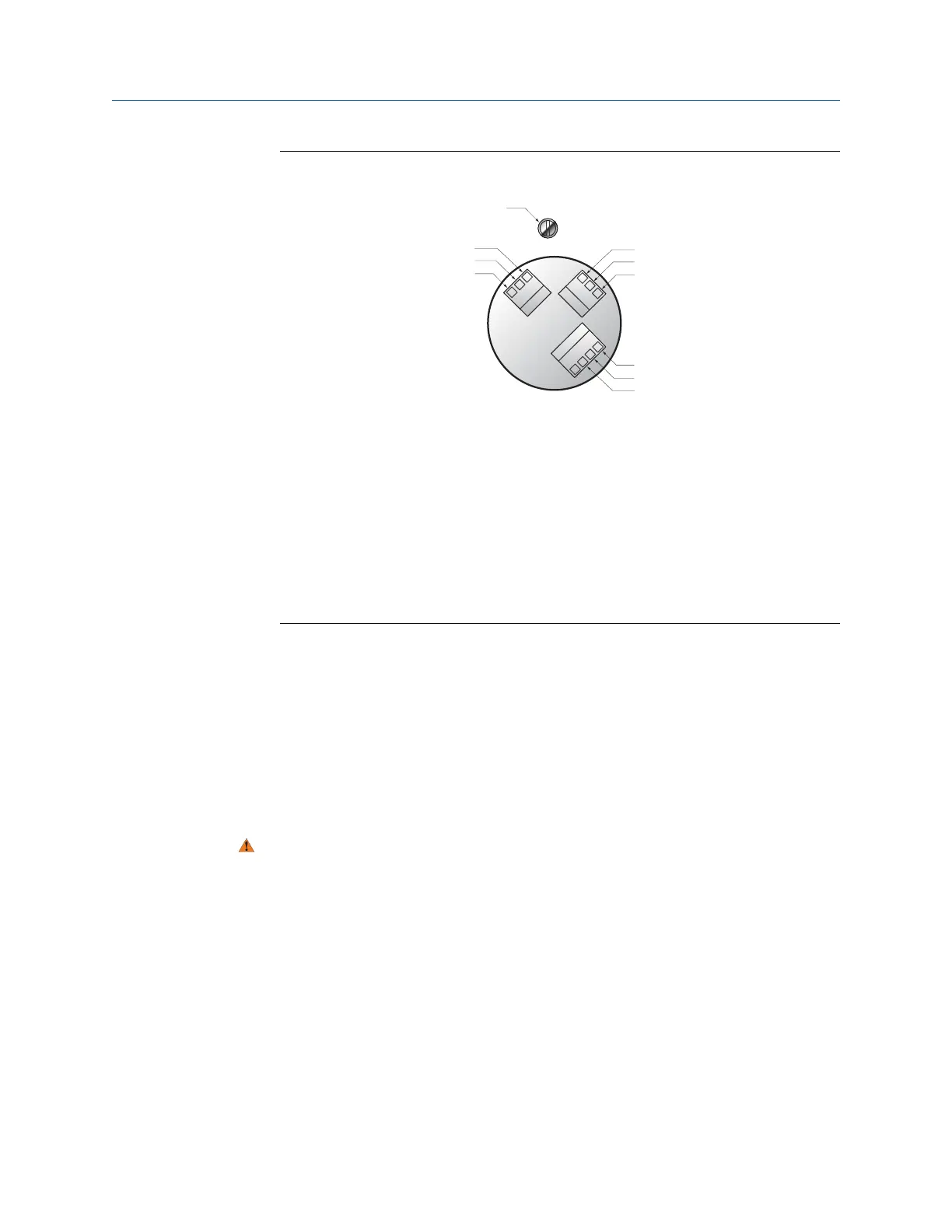

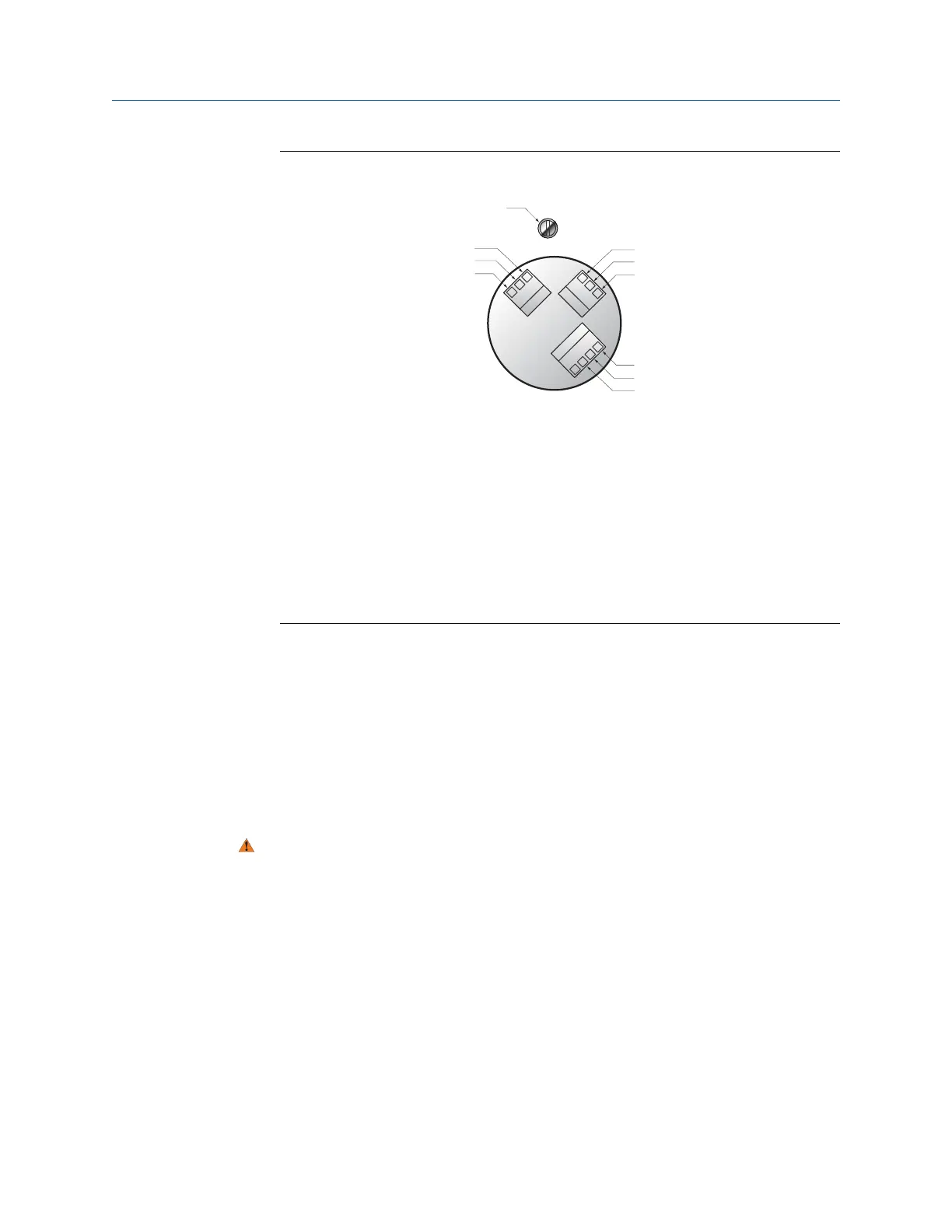

Enhanced core processor terminalsFigure 3-2:

A. Brown

B. Violet

C. Yellow

D. Orange

E. Gray

F. Blue

G. White

H. Green

I. Red

J. Ground screw (black)

3.1.2

Wire the core processor to the sensor using shielded

cable

Prerequisites

For hazardous area installations, shielded cable must be installed with cable glands at the

core processor end. Cable glands that meet hazardous area requirements can be

purchased from Micro Motion. Cable glands from other vendors can be used.

CAUTION!

• Sensor wiring is intrinsically safe. To keep sensor wiring intrinsically safe, keep the

sensor wiring separated from power supply wiring and output wiring.

• Keep cable away from devices such as transformers, motors, and power lines, which

produce large magnetic fields. Improper installation of cable, cable gland, or conduit

could cause inaccurate measurements or flow meter failure.

• Improperly-sealed housings can expose electronics to moisture, which can cause

measurement error or flowmeter failure. Install drip legs in conduit and cable, if

necessary. Inspect and grease all gaskets and O-rings. Fully close and tighten all housing

covers and conduit openings.

Procedure

1. Identify the components of the cable gland and cable.

Wiring

10 Micro Motion Liquified Natural Gas Meter

Loading...

Loading...